LASER SOLUTIONS AND INNOVATIVE BONDING PREPARATION IN TYRE INDUSTRY

TYRE INNER LINER CLEANING

Experience the expertise of Light Mechanics in solving problems related to laser cleaning of molds, surface treatment of tyres for effective bonding process and marking of tyres.

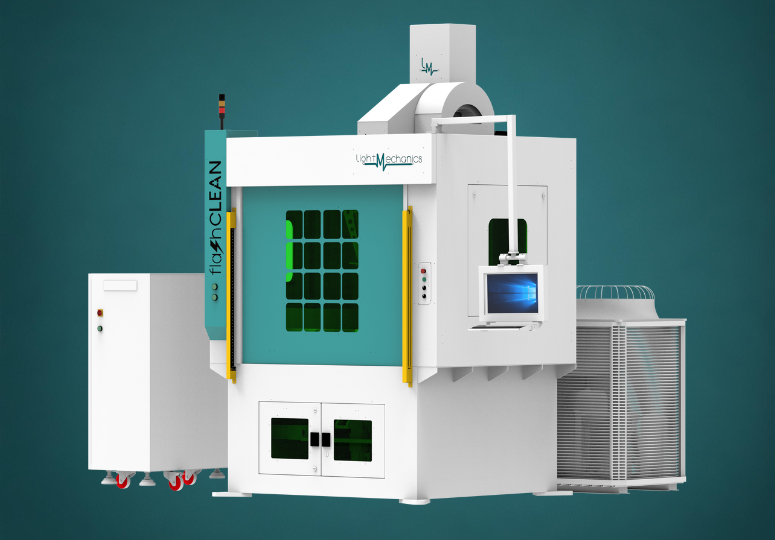

Our “flashclean” series provides Laser based Tire Cleaning solutions for cleaning the residue deposited on the innermost surface of self-healing tires, to facilitate good adhesion to the inner-liner while greatly reducing the time required to sufficiently clean the inner surface of tires. Our laser cleaning machine is suitable for efficient production line integration with consistent and selective laser cleaning process

ADVANTAGES OF “FLASHCLEAN” LASER CLEANING SYSTEMS:

- Removes releasing agents and oil residues for subsequent processes

- Prevents cracks or damage to the surface by removing the harmful residues

- Highly efficient compared to conventional cleaning methods

- Damage free tyre surface

- No residues left after cleaning

- Designed for maximum productivity

- Low maintenance system

- Provides high repeatability

- Suitable pre-treatment for subsequent processes like noise foam, RFID tags or sealants

- Dry cleaning process and post-process such as drying of moisture is not required

LASER TYRE MOLD CLEANING

In Tyre Industry, the surface quality of tyre molds strongly affects the quality of tyres. Hence mold cleaning forms a critical part of the manufacturing process. Tyre Molds requires to be cleaned every 1000-3000 tyres molded as contaminants may begin to build-up on the molds after days of use. Thus Tyre molds require frequent cleaning to remove residues from molding by products and release agents. Only perfectly clean molds deliver spotless tyres without blemishes and other defects.

Our “flashclean” systems are tailor-made to efficiently laser clean residue and contaminants from molds of the tyres.

ADVANTAGES OF “FLASHCLEAN” TYRE MOLD CLEANING

- Contactless and non-abrasive cleaning

- Maintains proper surface finish

- Removes pieces of rubber that gets attached to the mold

- Makes tyre codes in the mold readable and clear

- Keep the brand name and logo clearly legible

- Efficiently cleans the vents/ spring vents

- Avoids formation of surface irregularities

- Improves durability and reliability of the mold

- Reduces discarding of tyres damaged due to dirty mold

- Dry process with almost no consumable cost

- Flexibility for a variety of mold and profile geometries

- Lower running and maintenance costs with superior cleaning quality

- A noiseless alternative that does not damage the mold

- Minimal Emissions and reduced Carbon Footprint

- An easy-to-use solution where spacing is limited