INTEGRATING LASER SOLUTIONS FOR BATTERY ASSEMBLY LINES

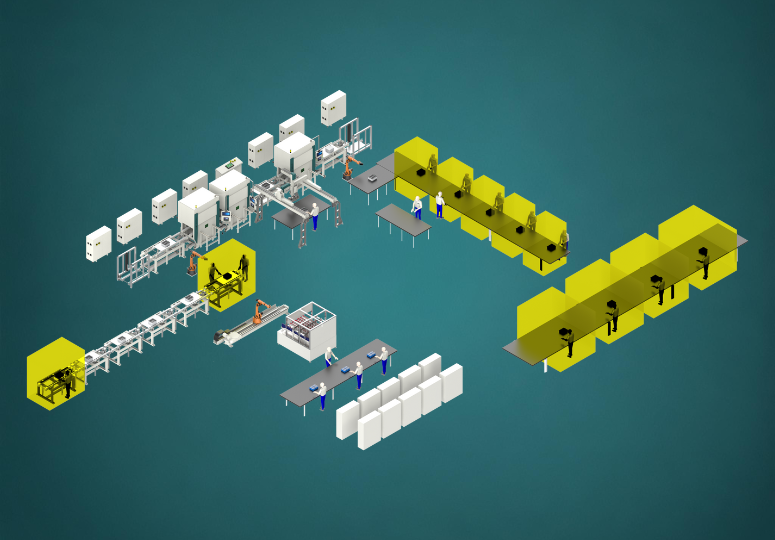

Light Mechanics is a leading supplier of laser equipments which provides end to end laser based solutions for battery assembly lines for EV and Battery industry. We integrate and combine our systems directly to battery assembly lines maintaining the height and width of the conveyor to match rest of the conveyor movement. Hence we directly support our customers in optimizing their battery production process while increasing the efficiency of the assembly lines with our ready to integrate laser, vision and weld monitoring systems.

Our machines can be used for power cylindrical, prismatic and pouch cell battery pack manufacturing. We also offer individual systems for small-scale as well as large-scale production. Our laser and vision system concepts are distinguished by their high production speed, high precision and reliability.

Our Solution

-

LOADING STATION

The battery module is loaded in this station and is clamped from all the sides to maintain stability during movement. Clamping process varies according to the battery type. Heavy battery modules can be clamped in trolley which eases the process of loading.

-

SIDE PLATE LASER WELDING SYSTEM

The battery module is loaded in this station and is clamped from all the sides to maintain stability during movement. Clamping process varies according to the battery type. Heavy battery modules can be clamped in trolley which eases the process of loading.

-

VISION SYSTEM

Visual inspection station detects the misplacement or misalignment of associated components such as battery sequence, side plates etc.

-

TERMINAL LASER CLEANING STATION

Removes potential contaminants from the surface of the terminals consisting of a masking unit to provide a clear line of sight to laser welding head. It is a pre welding process to enhance the strength of the weld. (Optional as per customer demand)

BUSBAR LOADING STATION

In this station the Bus bars are loaded on the battery module before moving to the next welding station.

BATTERY LASER WELDING STATION WITH INLINE WELD MONITORING

Here the busbars are laser welded to the cell terminals. It also includes the Inline weld monitoring system which performs the quality check during welding process by detecting the following:

- SEAM POSITION

- WORKPIECE HEIGHT

- KEYHOLE DEPTH

- FINISHED WELD SURFACE

- TRANSVERSE PROFILE

This setup reduces the chances of rejection by conducting a live weld test and shares details with the machine system to overcome the challenges of producing faulty battery packs.

UNLOADING STATION

After completion of all the process, welded battery module comes out to the unloading station where they are unloaded.

CONVEYOR SYSTEM

Our conveyor system can be customized in such a way that it can easily match the width and height of the conveyor to align and match it with the rest of assembly lines. In case conveyor

YOUR BENEFITS

Increased process and resource efficiency

Optimized process accuracy

Shorter Takt Times

Minimized Heat Affected Zones (HAZ)

Precision and Durability with low operating cost

Inline Weld Monitoring System