What factors need to be considered?

-

Solubility

-

Weldability

-

Inter-metallic compounds

-

Thermal expansion

-

Melting rates

-

Corrosion

-

End-service conditions

Once you have thoroughly investigated and considered the above factors, you can begin the welding process. Dissimilar metal welding is, for the most part, extremely similar to the welding of two similar metals. From smartphones to submarines, objects of all different sizes and from a variety of industries incorporate welding into their manufacturing process. This is done by physically melting the two metals together until they form one strong, connected joint. This fusion of metals is completed by using a high level of heat from the laser beam to cause the melting.

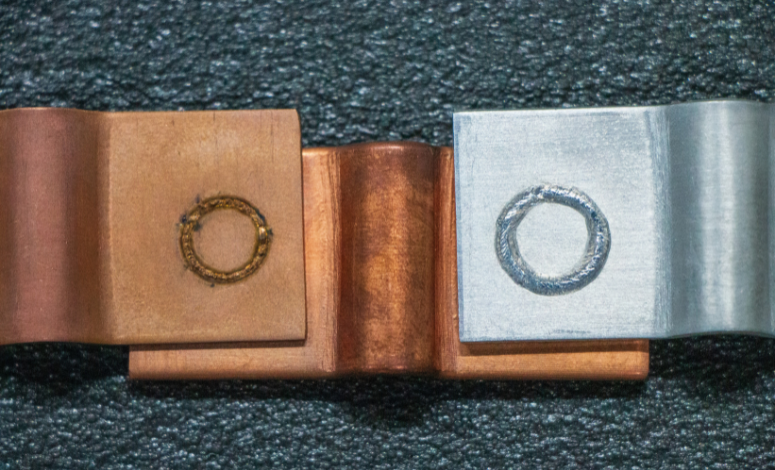

The complication with this type of welding is that often, two very distinct, very different metals may be getting welded together, which means it is not always as easy as simply melting the two parts together to form a bond. The problems arise in the transition zone between the two metals, where the intermetallic compounds are formed.

For a successful dissimilar metal weld to have taken place, the new forming joint needs to be as strong as the metal with the weaker tensile strength, so that you know the joint will be able to withstand any stresses that it faces