Laser Welding Systems for Process Stable, Consistent and High-Integrity Welds

Across modern manufacturing industries, including Automotive components, Powertrains and other industrial manufacturing, laser welding has become a preferred fusing technology due to its ability to deliver stable weld quality, controlled and high joint accuracy. By Using high power lasers, laser welding ensures consistent weld pool behaviour, controlled solidification and repeatable joint formation across a variety of components, motor parts and structural assemblies, meeting the demand for precision, reliability and scalable production in advanced manufacturing environments.

Why Laser Welding?

Laser welding offers superior process control and weld integrity compared to conventional

joining methods:

- Generates a narrow and controlled heat-affected zone (HAZ), reducing thermal distortion and residual stress

- Supports deep and consistent weld penetration with precise energy delivery

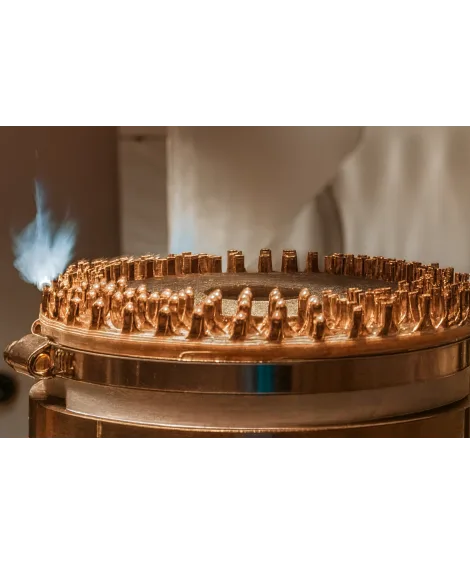

- Supports similar and dissimilar metal welding, including challenging metals like copper and aluminum, minimizing intermetallic compound formation

- Preserves mechanical integrity and material properties across welded joints

- Facilitates clean and precise fusion with minimal post-weld finishing requirements

- Fastest welding technology enabling single-pass high-speed welds without the need for fillers or electrodes.

Machine Quality and Welding Performance

Light Mechanics laser welding machines are engineered for continuous industrial operation

and long-term process stability ensuring consistent weld quality across high-volume

production:

- Robust industrial machine structure enables stable laser beam alignment

- Precision motion and optical control for consistent weld penetration and geometry

- Designed for spatter-free, pore-free and crack-free weld quality

- Built for continuous 24/7 industrial operation with in-house design, fabrication and assembly

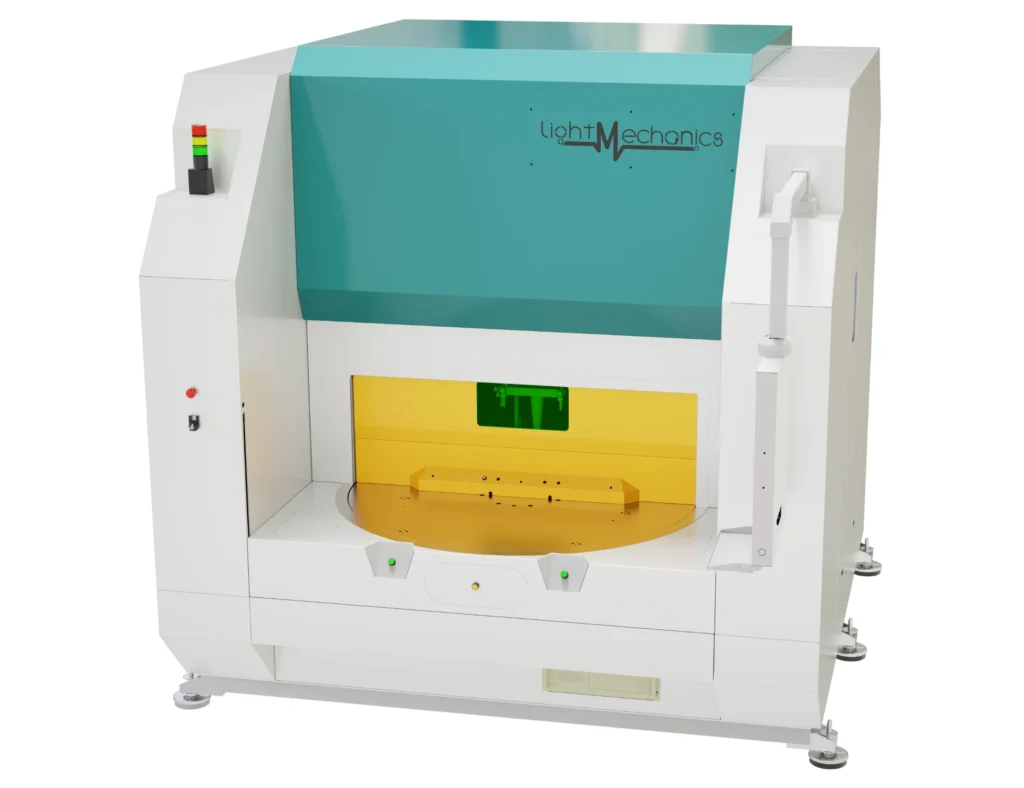

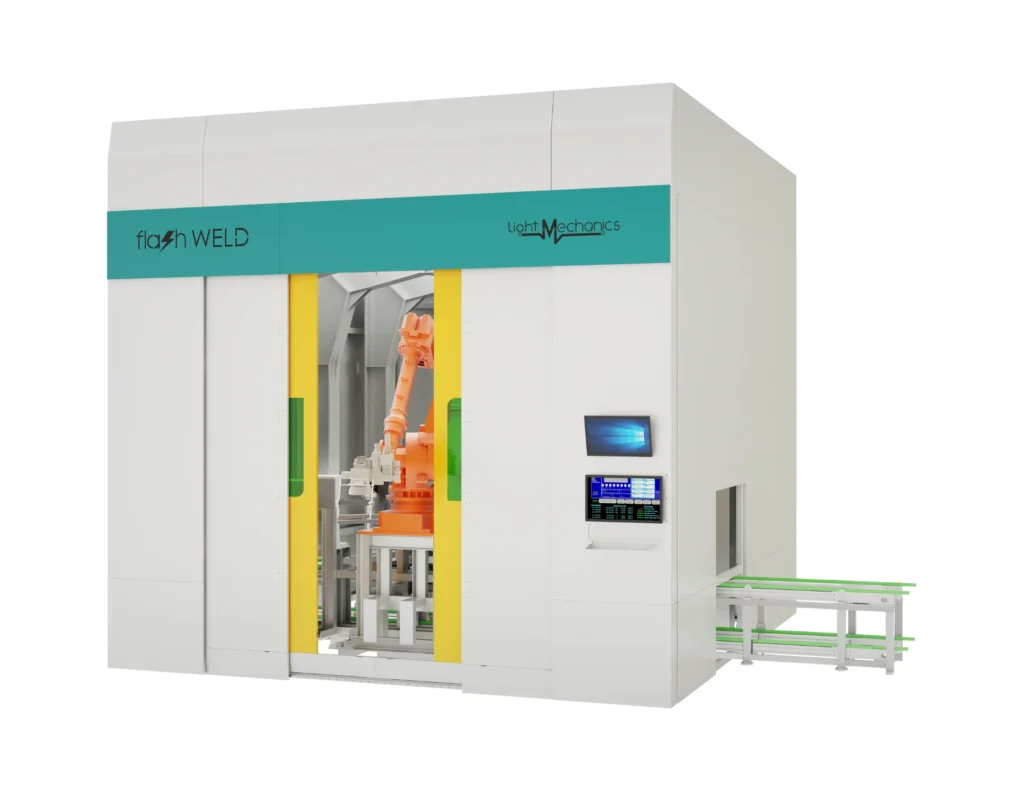

FlashWeld Series – Designed for Diverse Production Environments

The FlashWeld Series laser welding automation solutions are designed for manual, Semiautomated and fully automated laser welding applications, supporting a wide variety of

components while enabling scalable production across complex geometries, high-throughput

cycle times and evolving manufacturing requirements.

FlashWeld-S

Standalone Laser Welding System

A simple and flexible laser welding station designed for process development and low-to-medium volume production, offering precision welding with easy adaptability.

- High-precision welding with excellent repeatability

- Ideal for R&D, prototyping and pilot production

- Quick recipe changeover for different materials and joints

- Minimal setup complexity with semi-automatic operation for maximum flexibility

FlashWeld-CR

Conveyor-Based Inline Laser Welding System

An inline laser welding station engineered for continuous, automated production environments with faster cycle times and consistent weld quality.

- Seamless integration into automated conveyor lines

- Stable and repeatable weld penetration at high throughput

- Consistent inline process control across multiple shifts

- Suitable for medium to heavy components

- Enable automated loading and unloading

FlashWeld-RI

Rotary Indexing Laser Welding Machine

A rotary indexing laser welding system optimized for high-volume production of small and lightweight components requiring identical welds.

- Reduced takt time through synchronized indexing

- Precise and repeatable part positioning

- Simultaneous loading, welding and unloading operations

- Compact system design with high productivity

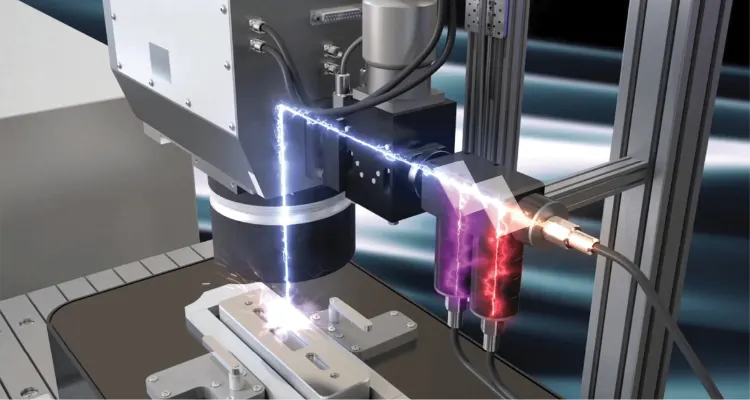

FlashWeld-RB

Robotic Laser Welding Cell

A robotic laser welding solution integrating a 6-axis industrial robot to weld complex, large or geometrically challenging components with high flexibility.

- Multi-axis seam access for complex weld paths

- Consistent weld quality across varying geometries

- High flexibility for product variations and automation

- Ideal for large assemblies and structural components.

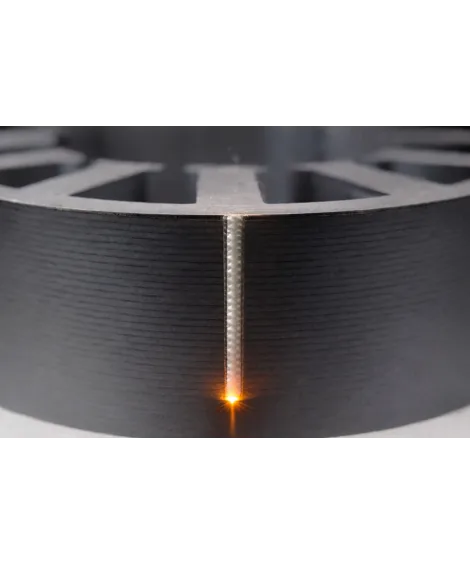

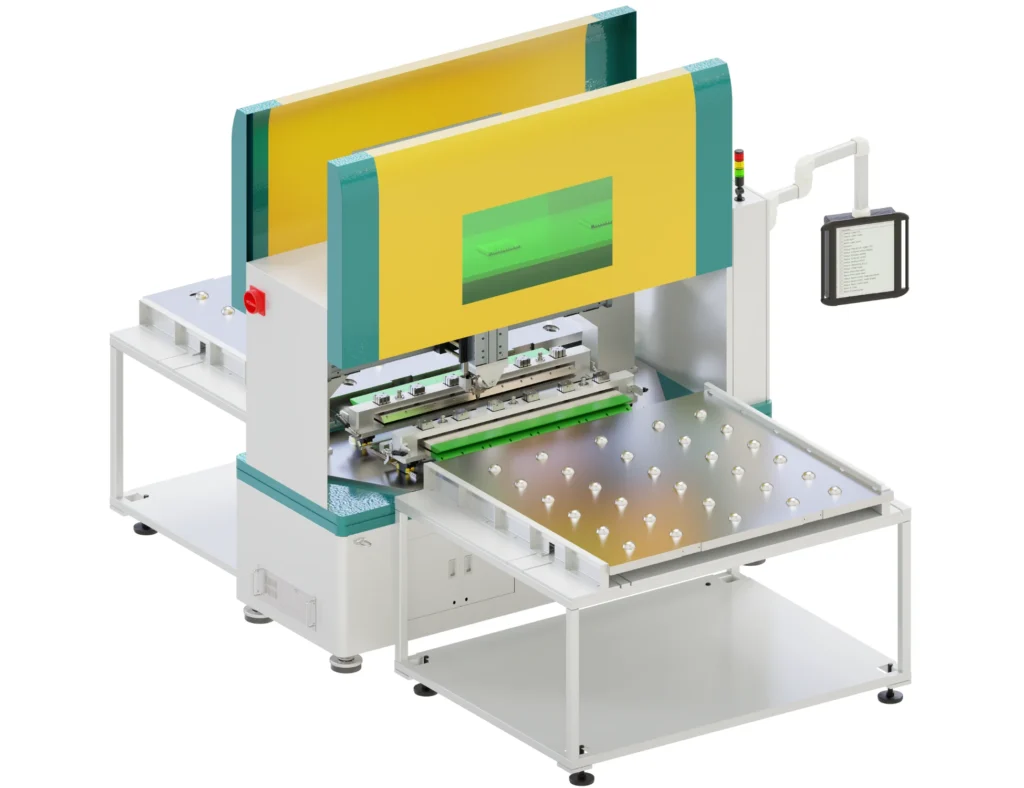

Flash-CrossWeld 200

Laser Cross Welding System for Narrow Coils

Flash-CrossWeld 200 is a precision laser cross welding system engineered for continuous joining of narrow metal tapes and thin coils in high-accuracy processing lines. It ensures clean, defect-free welds with minimal heat input, enabling smooth downstream rolling, stamping and forming operations.

- High-precision laser cutting and butt welding of thin materials

- Smooth, flat weld seams suitable for rolling and stamping

- Minimal heat input with very low material distortion

- Ideal for electrical steel and precision strip processing applications

- Supported Tape Materials: Steel, Stainless Steel, Aluminium, Copper, Electrical Steel, Composites, and alloys of Al, Cr, Ni, Ti

- Tape / Coil Width: 20 mm to 200 mm

- Tape / Coil Thickness: Stainless Steel: 0.05 mm - 2 mm, Aluminium: 0.10 mm - 2 mm, Copper: 0.10 mm - 1 mm.

Flash-CrossWeld 1400

High-Capacity Laser Cross Welding System for Wide Coils

A high-performance laser cross welding solution designed for wide and thicker metal coils in high-throughput industrial production lines.

- Uniform weld integrity across full strip width

- Supports large coil widths and higher thickness ranges

- Designed for continuous, high-speed production

- Reliable integration into automated stamping and coil lines

- Tape Materials: Steel, Stainless Steel, Aluminium, Copper, Composites, Alloys of Al, Cr, Ni, Ti, Electric Steel etc.

- Tape/Coil Width: 400 - 1400mm

- Tape/Coil Thickness: 0.15mm - 3mm SS, 0.20mm - 2.5mm Al, 0.10mm - 1.2mm Cu

Advanced Welding Intelligence & Process Control Features

Light Mechanics laser welding systems integrate advanced monitoring and control

technologies to ensure consistent weld integrity:

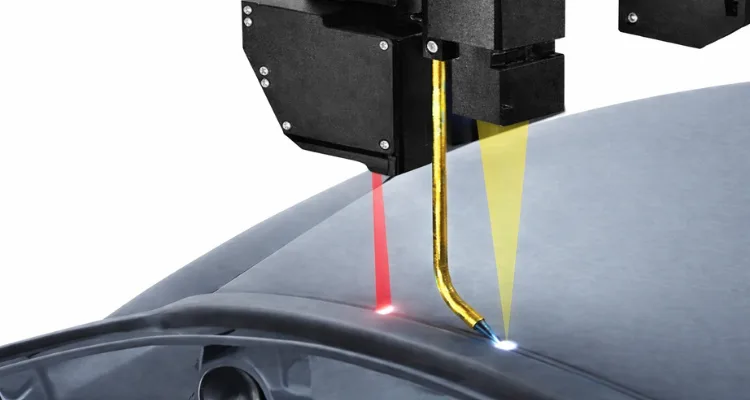

Inline Weld Monitoring

Inline weld monitoring continuously measures weld penetration depth, material height variation and transverse weld profiles. This enables real-time quality assurance, immediate defect detection and closed-loop process control without interrupting production.

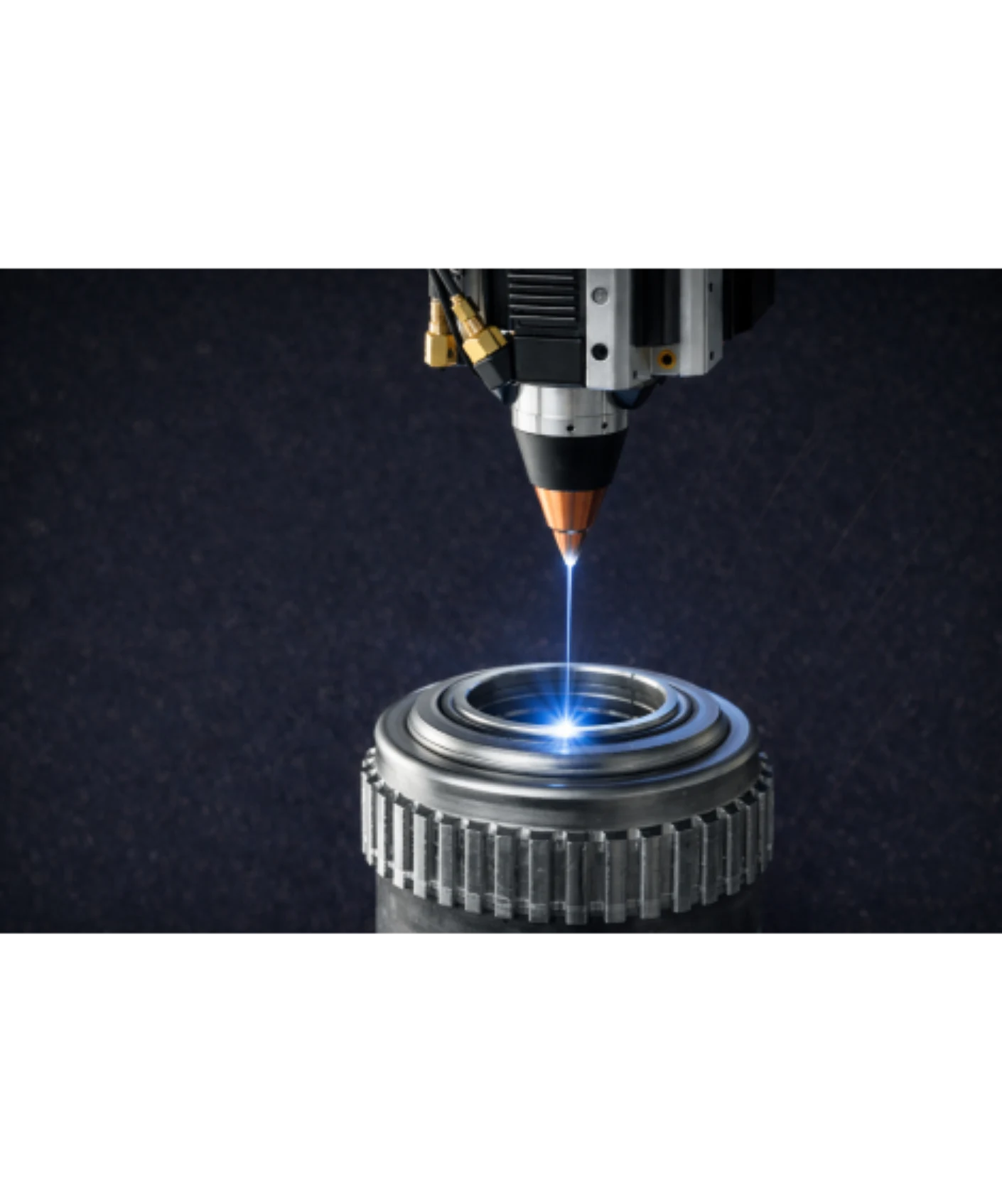

Seam Tracking

Seam tracking technology allows the laser beam to dynamically follow the actual joint location during welding. By compensating for part tolerances and alignment variations, it ensures accurate laser placement, uniform weld geometry and reduced defect rates.

Vision System Integration

Integrated vision systems detect part presence, orientation, and position before and during welding. This enables the system to adapt in real time, improving repeatability, reducing scrap and enhancing overall process reliability.

Industry 4.0 Integration

FlashWeld laser welding systems are designed for smart manufacturing environments:

- PLC-based, recipe-driven welding programs

- MES integration for data logging and traceability

- Inline automation for reduced manual handling

- Fully customized layouts aligned with production workflow

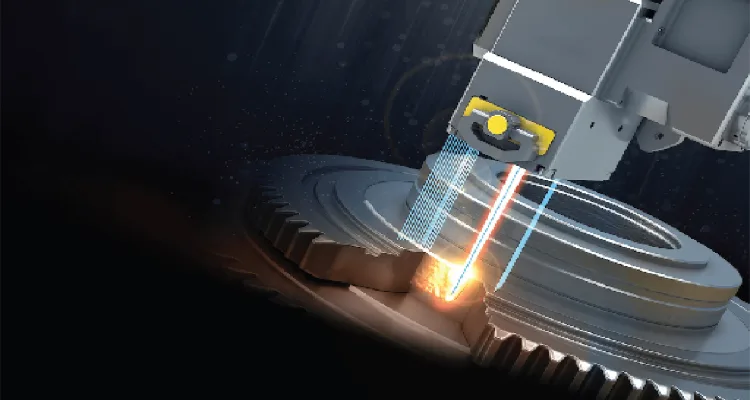

Laser Technologies Supported

FlashWeld systems support a wide range of industrial laser sources to match application

requirements:

- Continuous Wave (CW) lasers for deep penetration welding

- Pulsed and QCW lasers for controlled heat input and thin materials

- Single-mode and multi-mode lasers for precision, high power micro welding

- Dual beam lasers using core and ring technology for advanced, spatter-free and critical welding applications

Engineered for Precise Fusion and Weld Integrity

Light Mechanics laser welding systems are engineered to meet evolving manufacturing

demands where precision, automation and weld consistency are essential. With modular

system designs, intelligent monitoring and advanced automation capabilities, the FlashWeld

series enables manufacturers to achieve reliable weld quality while scaling production

efficiently across demanding environments.