Why Light Mechanics?

Advanced Welding Intelligence & Process Control Features

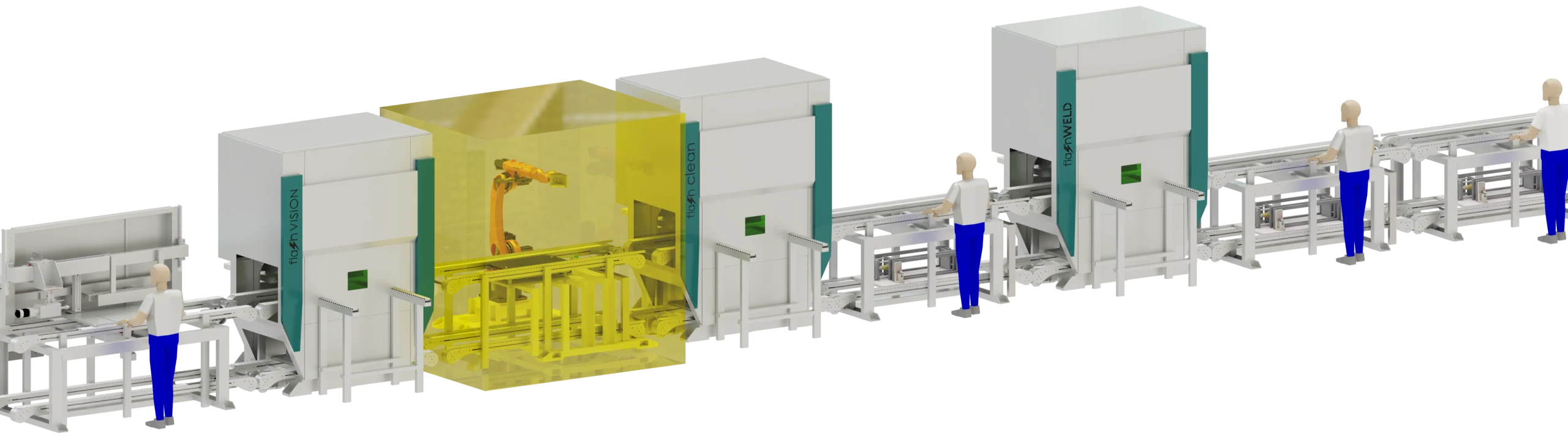

End-to-End Laser Solutions

We go beyond supplying machines. Our team studies your complete manufacturing process and delivers a fully integrated laser solution - from system design and automation to peripherals, safety and long-term support. With Light Mechanics, you work with one partner who takes complete responsibility for the performance, integration and success of the solution.

Our Expertise

Our laser system automations are built for demanding production environments where reliability and consistency are critical. Along with high-speed laser platforms, we bring deep expertise in integrating vision systems, seam tracking solutions and inline weld monitoring to achieve precise and repeatable results. We place strong emphasis on cycle time and throughput optimization to maximize productivity without compromising quality. All our systems are supported by remote diagnostics and real-time technical assistance. As a result, every solution we deliver is engineered for long-term reliability, maximum uptime, scalability and continuous 24/7 production.

Guaranteed Safety

At Light Mechanics, safety is fundamental to every system we design. All machines are engineered with Class-1 laser safety as a priority, ensuring safe operation for operators and surrounding equipment. Our solutions incorporate fully enclosed safety designs, certified interlocks, efficient fume and particle extraction and specialized configurations for heat-sensitive materials. This allows you to focus entirely on production, knowing that safety is fully taken care of.

Innovation-Driven Processes

Our engineers and laser specialists continuously push the boundaries of laser technology. When standard solutions are not sufficient, we develop new processes tailored to advanced and complex requirements. From precision marking and welding to surface cleaning and texturing, we design laser processes that deliver consistent performance, even under challenging post-processing conditions.

High Speed & Optimized Performance

Speed is critical in modern manufacturing. Our laser systems are optimized at every level, including laser parameters, optical components, automation design and process sequencing. This holistic optimization delivers maximum throughput without compromising quality, resulting in faster cycle times, higher productivity and improved return on investment.

Real-Time Remote Support

All Light Mechanics systems are equipped with secure remote access capabilities, enabling rapid diagnostics, instant technical assistance and remote training or process optimization. This minimizes downtime and allows production to resume quickly, often within minutes.

Trusted Technology Partners