Why Laser Battery Welding Is More Complex Than It Looks

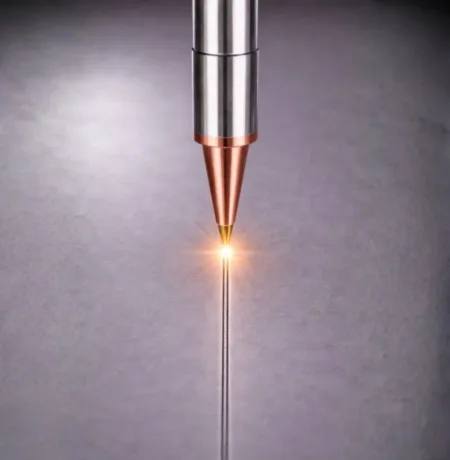

Laser welding has become the backbone of modern EV battery and energy storage

manufacturing. From cell tabs and busbars to terminals and housings, lasers enable highspeed, low-distortion joining that traditional welding methods cannot match.

At first glance, laser battery welding may seem simple.

- Customized gantry dimensions based on battery module size

- Precision motion for cell-to-busbar and terminal welding

- Advanced vision systems for weld position correction

- Integrated press-and-weld systems to reduce air gaps

- In-built conveyor for automated line integration

- Upgradable with Inline Weld Monitoring System

- Integrated cooling, fume extraction and safety enclosures

But in reality, it is one of the most demanding and safety-critical joining processes in battery

manufacturing. Even micron-level variations in components or process conditions can affect

electrical conductivity, mechanical strength, thermal behaviour and long-term battery safety.

The factors influencing weld quality can be grouped into five core areas: Materials,

Geometry, Tooling, Laser process, Automation and Monitoring.

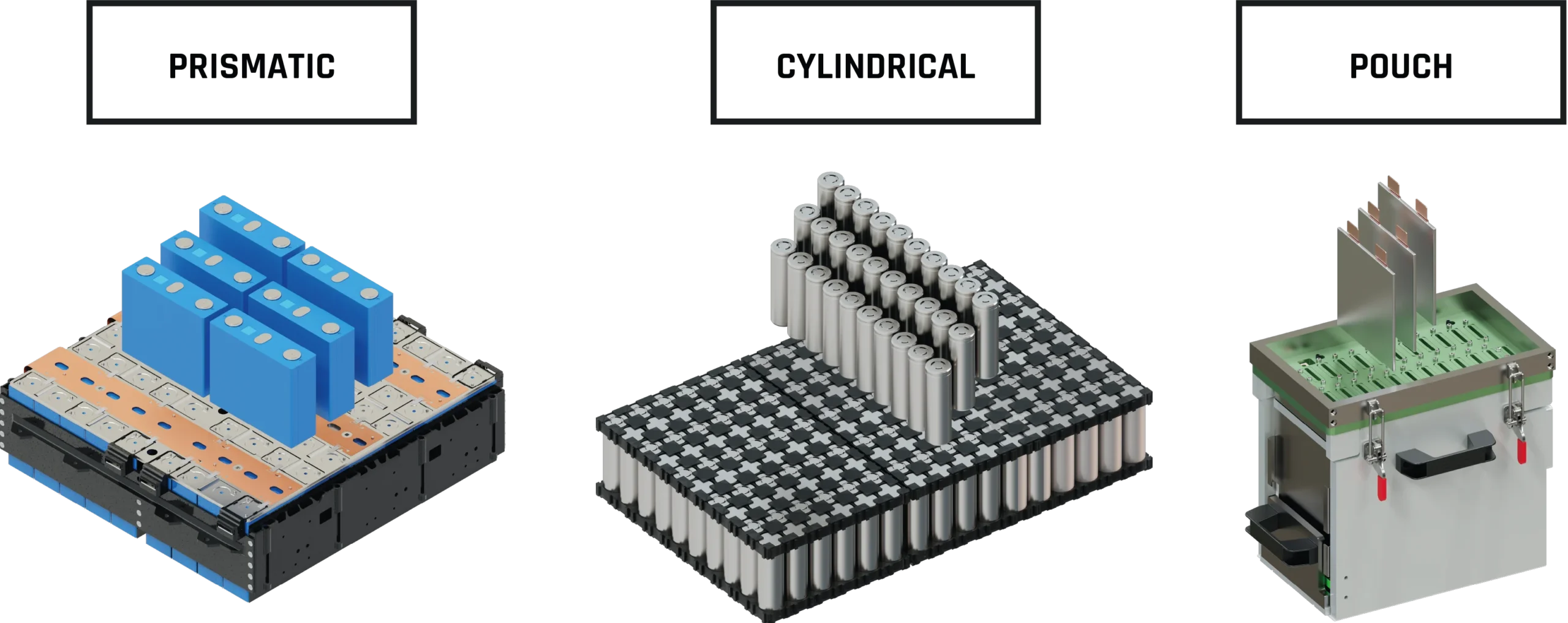

1. Cell-to-Cell Height Variation and Geometry

In real battery production, no two cells are perfectly identical. Variations arise from

manufacturing tolerances, stacking errors, material and busbar inconsistencies.

Laser welding is extremely sensitive to focus position. Small changes in cell height or joint

geometry can cause the laser focal point to shift away from the optimal plane.

Impact on weld quality:

- Inconsistent penetration depth

- Wider or unstable weld pools

- Increased spatter and porosity

- Reduced electrical and mechanical strength

Without active height compensation, these variations can result in weak or latent defects

that only appear after cycling.

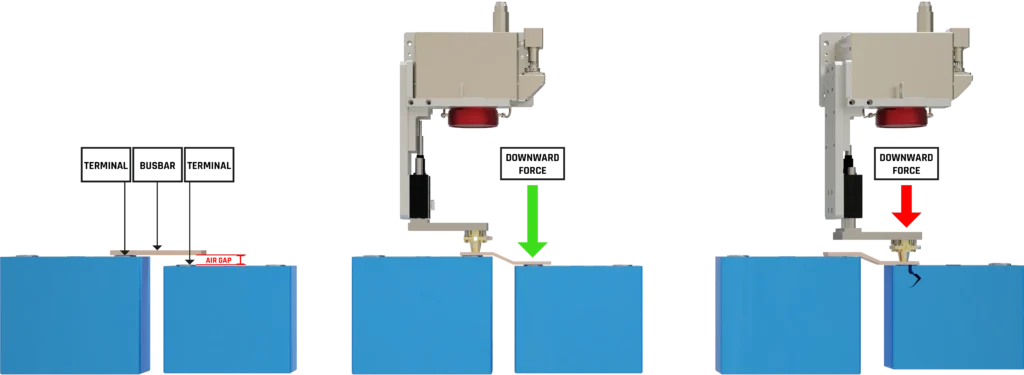

2. Assembly Accuracy and Fit-Up Quality

Proper joint fit-up is essential for stable laser welding. Misalignment between tabs, busbars

and cell terminals compromises weld integrity of the joint.

Even microscopic air gaps between joining surfaces can act as thermal barriers, preventing

consistent keyhole formation.

Impact on weld quality:

- Incomplete fusion

- High electrical resistance

- Irregular weld geometry

- Increased reject rates

Precision assembly and consistent positioning are critical for repeatable results.

3. Material Type, Coatings and Variability

Battery welding involves challenging materials such as Copper, Aluminum, Hilumin, Nickel,

Alloys and other plated substrates. These materials when welded together, differ

significantly in reflectivity, melting point and thermal conductivity.

Dissimilar metal joints further complicates the process due to uneven melting behaviour and

metallurgical incompatibility (low miscibility).

Impact on weld quality:

- Back reflection and unstable absorption of laser energy

- Formation of brittle intermetallic compounds (IMCs), hot cracks, porosities and uneven mixing of metals

- Reduced joint strength and increased contact resistance

Material batch variations and coating thickness inconsistencies can also shift the welding

process window considerably.

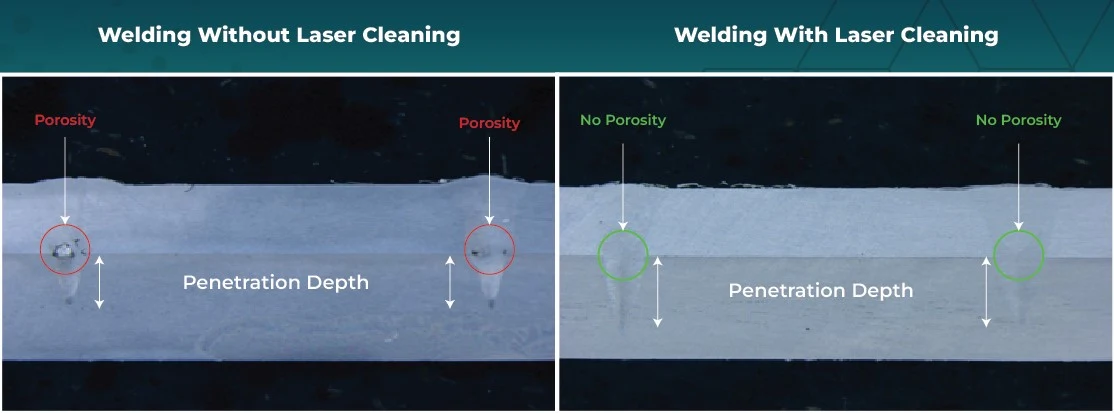

4. Surface Condition and Cleanliness

Laser welding requires clean, oxide-free surfaces. Contaminants such as oil, moisture, dust

or oxide layers interfere with laser energy absorption and molten pool stability.

Trapped contaminants can vaporize during welding, resulting in increased spatters and

results in internal voids and porosity

Impact on weld quality:

- Gas cavities, voids and porosity

- Excessive spatter generation

- Reduced joint strength and increased contact resistance

Consistent cleaning and controlled production environments are essential.

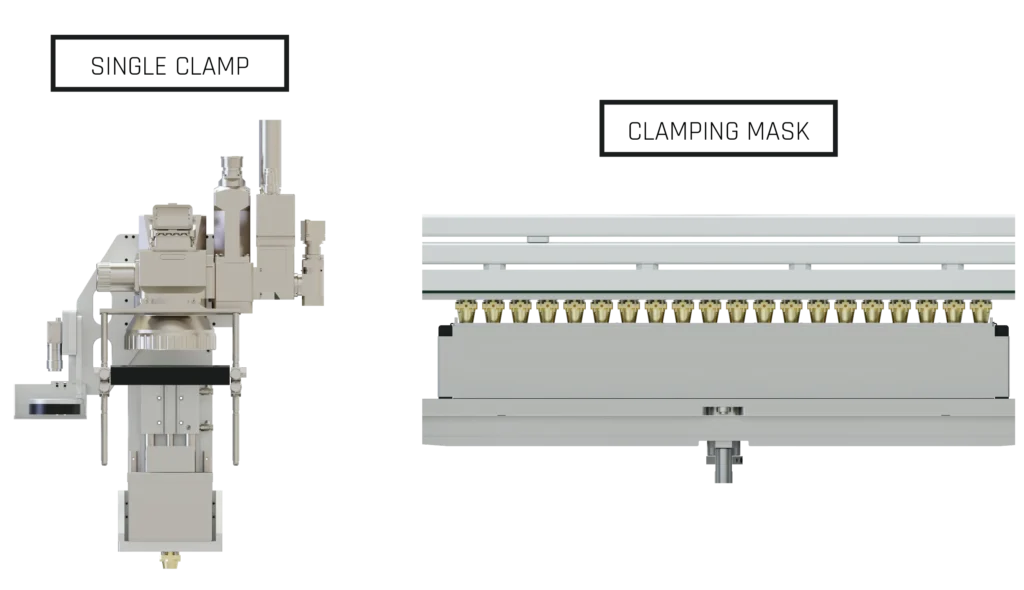

5. Tooling plays a defining role in battery laser welding.

Poorly designed fixtures or non-uniform clamping forces can introduce air gaps, distort

components and cause positional variation during welding.

Tooling systems without vision or sensing feedback may struggle to accommodate part-topart tolerance variations, while insufficient or unstable clamping can allow component

movement and air-gaps during welding – resulting in inconsistent weld quality and

unacceptable defects.

Impact on weld quality:

- Variable penetration and fusion

- Weld misplacement

- Electrical performance variability

A precision-engineered, thermally stable and compliant tooling is critical for consistent weld

quality in battery welding.

6. Laser Focus Position and Beam Delivery

The quality of a laser weld depends heavily on the type of laser, its beam quality, spot size

and focus stability.

Even slight deviations in focus caused by cell to height variations, optics contamination and

mechanical vibrations can significantly alter energy density at the weld joint.

Impact on weld quality:

- Over-penetration or lack of penetration

- Excessive heat-affected zone

- Inconsistent weld nugget geometry

Stable and defect free-optics, proper maintenance and focus monitoring are essential for

good battery welding.

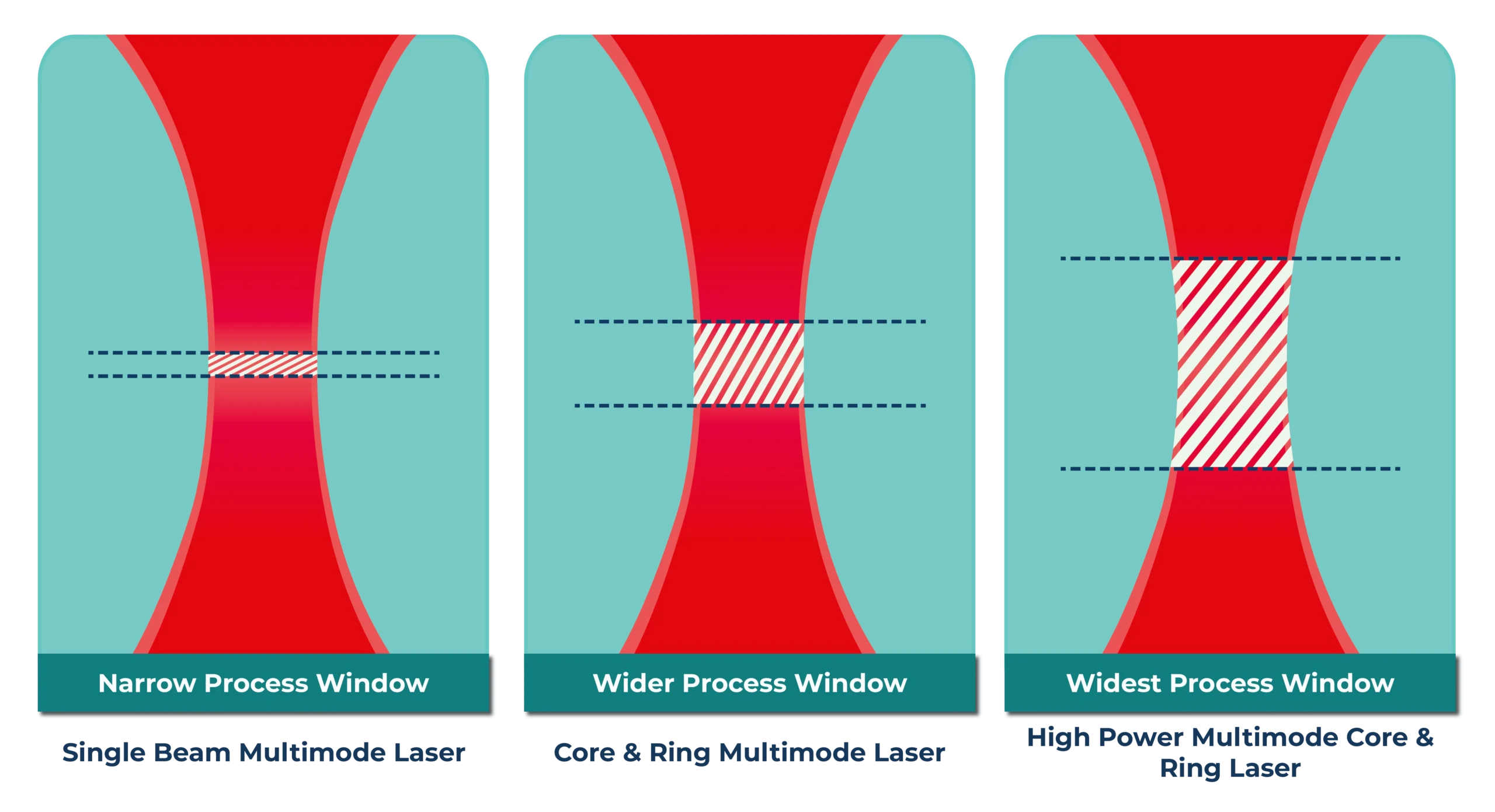

7. Laser Power Stability and Energy Control

Laser power stability refers to the ability of a laser source to deliver consistent output energy

over time. Battery laser welding demands highly precise and repeatable energy input, as

even small power fluctuations can destabilize the weld pool.

In addition, inconsistent pulse shaping can cause sudden energy spikes, leading to weld pool

instability and material ejection in the form of spatter.

Highly conductive materials such as copper and aluminum further increase process

sensitivity, requiring tight control over power ramps, pulse duration and peak energy to

achieve stable penetration and fusion.

Impact on weld quality:

- Porosity and micro-cracking

- Excessive spatter and metal ejection

- Inconsistent or variable penetration depth

Selecting a robust laser source with advanced power regulation, precise pulse shaping,

optimized beam control and beam shaping feature significantly improves process stability

and overall weld integrity.

8. Welding Speed and Motion Accuracy

Laser welding quality is directly influenced by travel speed and motion system accuracy.

Inconsistent speed, vibration or backlash in motion systems leads to uneven energy

distribution along the weld seam.

Impact on weld quality:

- Irregular weld bead

- Localized overheating or lack of fusion

- Poor repeatability across parts

High-precision motion systems are essential, especially in high-throughput battery assembly

lines.

9. Spatter and Particle Management

Spatter is not merely a cosmetic concern in battery laser welding. It consists of molten metal

droplets ejected from the weld pool that can adhere to surrounding surfaces and create

serious risks in battery manufacturing. Spatter represents material loss from the weld zone,

reducing the amount of material available for proper fusion and weakening the joint.

More critically, spattered metal particles can contaminate sensitive battery components,

increasing the risk of internal short circuits and long-term reliability issues.

Spatter generation is strongly influenced by energy density, focus stability, surface conditions

and shielding gas effectiveness.

Impact on weld quality:

- Material removal from weld zone

- Damage to separators and insulation layers

- Increased risk of internal electrical failure

As a result, spatter-minimized welding strategies are mandatory in battery applications to

ensure weld integrity, electrical safety and long-term performance. In addition, excessive

spatter can contaminate and damage welding optics, leading to reduced beam quality,

process instability and increased maintenance downtime.

10. Thermal Management and Heat Dissipation

Excessive heat input can damage nearby battery components or alter material properties. At

the same time, insufficient heat leads to poor fusion.

Impact on weld quality:

- Heat-affected zone growth

- Distortion of thin components

- Reduced mechanical strength

Thermal balance is critical for reliable battery welds.

11. Automation Stability and Repeatability

Battery welding systems operate continuously at high speeds. Any instability in automation –

such as vibration, backlash or inconsistent loading – directly affects weld quality.

Impact on weld quality:

- Positional errors

- Process variability

- Increased defect rates

Robust automation ensures repeatable performance over long production cycles.

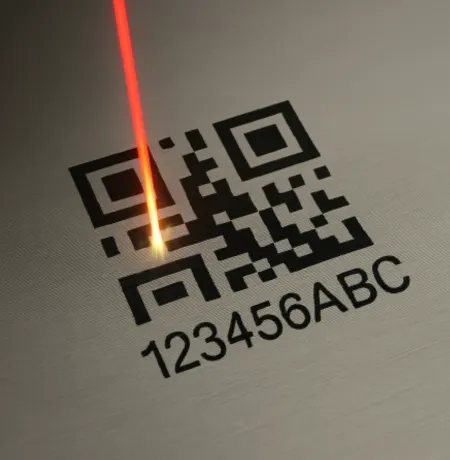

12. Inline Monitoring and Process Control

Inline monitoring and process control in battery welding offer significant advantages

in quality assurance, cost efficiency and safety. By detecting flaws in real-time,

manufacturers can ensure a zero-defect target and create durable, reliable batteries

essential for electric vehicles and other applications.

Impact on production:

- 100% inspection and early detection of defects

- Reduced scrap and rework

- Improved traceability and compliance

- Enables immediate process adjustments

Process monitoring is no longer optional in battery welding. It has become an important tool

of battery laser welding systems.

Conclusion

In battery manufacturing, welding is no longer just a process step – it determines

performance, yield, and long-term reliability. As production volumes grow and designs

evolve, the margin for error shrinks. Success comes not from access to laser technology, but

from controlling its complexity at scale.

This is where Light Mechanics makes the difference. Whether you are developing a new

battery platform or scaling to high-volume production, the right laser welding system

transforms uncertainty into production confidence.

Light Mechanics partners with battery manufacturers to deliver application-specific laser

welding solutions that ensure consistent quality, stable throughput and long-term reliability.

Take the next step:

- Talk to our experts about your battery welding challenges

- Explore battery-first laser welding systems from Light Mechanics

Article By:

Shipra Sinha

(Director – Sales & Marketing)

LinkedIn: http://www.linkedin.com/in/shipra-sinha-50179961

(Director – Sales & Marketing)

LinkedIn: http://www.linkedin.com/in/shipra-sinha-50179961