Metal Coil Processing - Laser Cross Welding

Application Demand

In high-volume metal processing, coils must be joined end-to-end to maintain continuous

rolling, stamping or forming operations. The joints must be strong, defect-free and smooth to

prevent disruptions in downstream processes. This is especially critical for electrical steels

and grain-oriented electrical steels, where coil thicknesses range from 30 µm to 300 µm.

Precise welding angles and uniform fusion are required to minimize defects, reduce scrap

and maintain material performance.

What Laser Enables

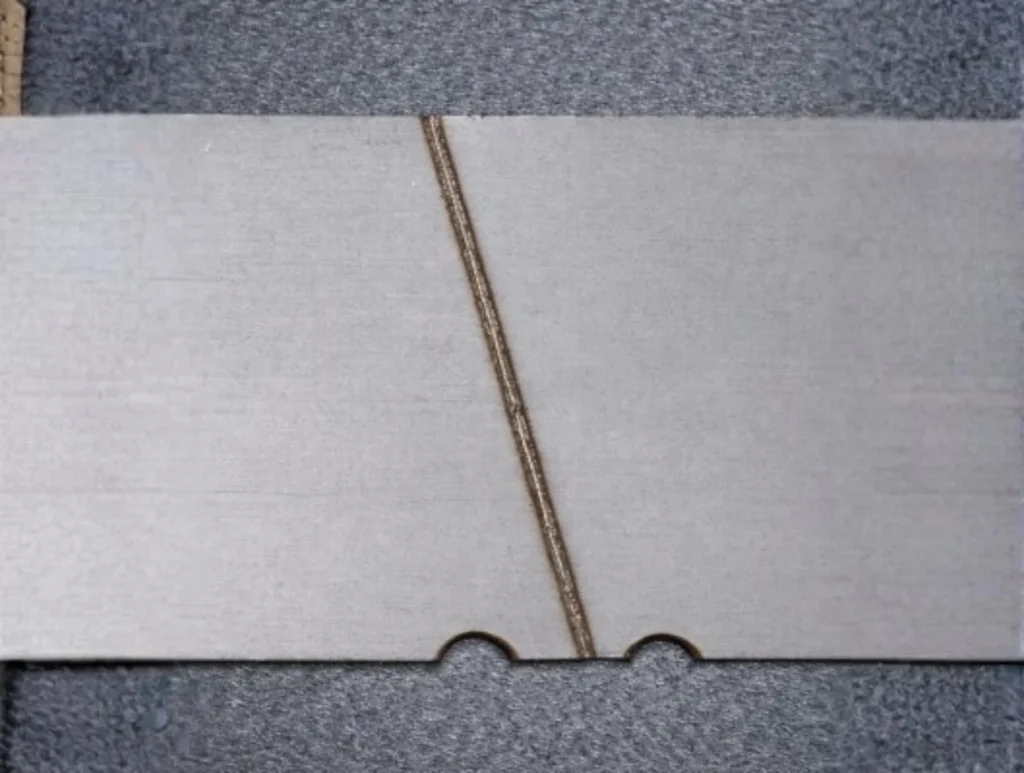

Laser cross welding provides high-strength, consistent and defect-free cutting and joining of

metal coils together. The non-contact process ensures smooth transitions, precise angle

cutting and welding with minimal heat-affected zones, even on ultra-thin materials. It

improves production efficiency, reduces material scrap and supports high-speed, automated

coil processing while maintaining metallurgical integrity and electrical performance of the

steel.

Supported Materials

- Steel, Stainless Steel, Aluminium, Copper, Composites

- Alloys of Al, Cr, Ni, Ti, Electric Steel

Tape/Coil Specifications

- Width: 20 mm to 1400 mm (depending on system)

- Thickness:

- Steel: 0.15 - 3 mm

- Stainless Steel: 0.05 - 2 mm

- Aluminium: 0.10 - 2.5 mm

- Copper: 0.10 - 1.2 mm

Core Capabilities

- Precision Laser Cutting - Burr-free, accurate edges for delicate and thin materials

- High-Quality Butt & Cross Welding - Defect-free, smooth and strong joints for continuous coil processing

- Tape/Coil Flattening - Ensures uniform material thickness for downstream rolling, stamping and forming.

Why Choose Light Mechanics?

Light Mechanics delivers advanced laser solutions for metal coil processing, enabling highprecision cutting, welding and flattening. Our systems are designed for high-speed

automation, full process control, minimal waste and consistent high-quality output,

supporting modern manufacturing requirements across electrical steels, thin metal foils and

specialty alloys.