Laser Applications for Medical Industry

The medical device industry demands extreme precision, biocompatibility and traceability in

the manufacturing of critical components. Laser-based processes have become indispensable

due to their ability to deliver non-contact, high-precision material processing with minimal

thermal impact. From cardiovascular stents to surgical instruments and orthopedic implants,

lasers enable reliable, repeatable and scalable production while maintaining regulatory

compliance and patient safety.

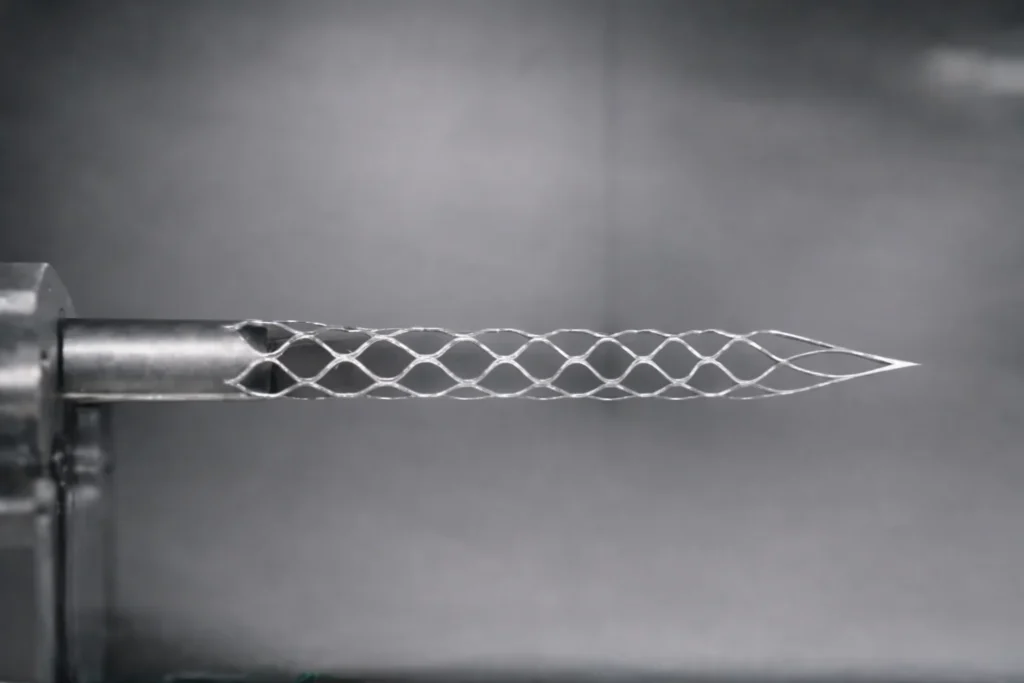

Stent Laser Cutting

Application Demand

Cardiovascular stents, commonly made from Nitinol shape memory alloy (NiTi) and Stainless steel (316L), cobalt-chromium or stainless steel,

require ultra-precise fabrication with complex geometries. Tight dimensional tolerances,

smooth edges and consistent structural integrity are essential to ensure proper expansion,

fatigue resistance and biocompatibility, minimizing the risk of tissue damage and ensuring

patient safety.

What Laser Enables

Laser cutting delivers burr-free stent structures with micron-level accuracy and minimal heataffected zones. The non-contact process ensures smooth edges, repeatable dimensions and

high-yield production. Laser processing preserves material properties, maintains mechanical

integrity and supports regulatory compliance for cardiovascular implants.

Plastic and Metal Medical Equipment Marking

Application Demand

Surgical instruments, implants and medical devices require permanent, legible and

sterilization-resistant markings for traceability, regulatory compliance and batch

identification. These markings must withstand sterilization, chemicals, rusting, abrasion and

long-term use without compromising device functionality.

What Laser Enables

Laser marking provides fast, high-contrast and durable laser marks on metal and plastic

medical devices without any contact or consumables. The process ensures precise, repeatable

and sterile markings that withstand cleaning, sterilization and mechanical wear supporting

full lifecycle traceability and quality assurance.

Laser Polishing

Application Demand

Medical implants, surgical instruments and high-precision medical components demand exceptionally smooth, defect-free surfaces to ensure biocompatibility, patient safety and long-term clinical performance. Even minor surface irregularities, micro-cracks or residual roughness can promote bacterial adhesion, accelerate corrosion, increase wear and reduce fatigue life. As a result, polishing processes must comply with stringent medical and regulatory standards while preserving tight dimensional tolerances, material properties and functional integrity of the device.

What Laser Enables

Laser polishing enables controlled thin surface layer melting and reflow to significantly reduce surface roughness on metal medical components without mechanical contact or abrasives. The process produces smooth, uniform and contamination-free surfaces, improving cleanability, corrosion resistance and fatigue strength. Laser polishing delivers highly repeatable results, supports complex geometries and is ideal for medical implants and devices requiring superior surface quality, enhanced hygiene and long-term reliability.

Why Choose Light Mechanics

Light Mechanics delivers application-driven laser solutions for the medical industry that

combine high precision, repeatability and automation compatibility. Our systems are

optimized for high-volume production while maintaining material integrity, regulatory

compliance and traceability. With expertise across stents, implants surgical tools Light

Mechanics enables medical manufacturers to meet stringent quality and performance

standards while improving productivity and process reliability.