Customizable Automation Solutions

Light Mechanics machines support a wide range of customizable automation configurations to match varying production volumes, component dimensions, and line layouts. Each setup is engineered to align with specific process requirements, ensuring controlled operation, stable cycle times and scalability as manufacturing needs evolve.

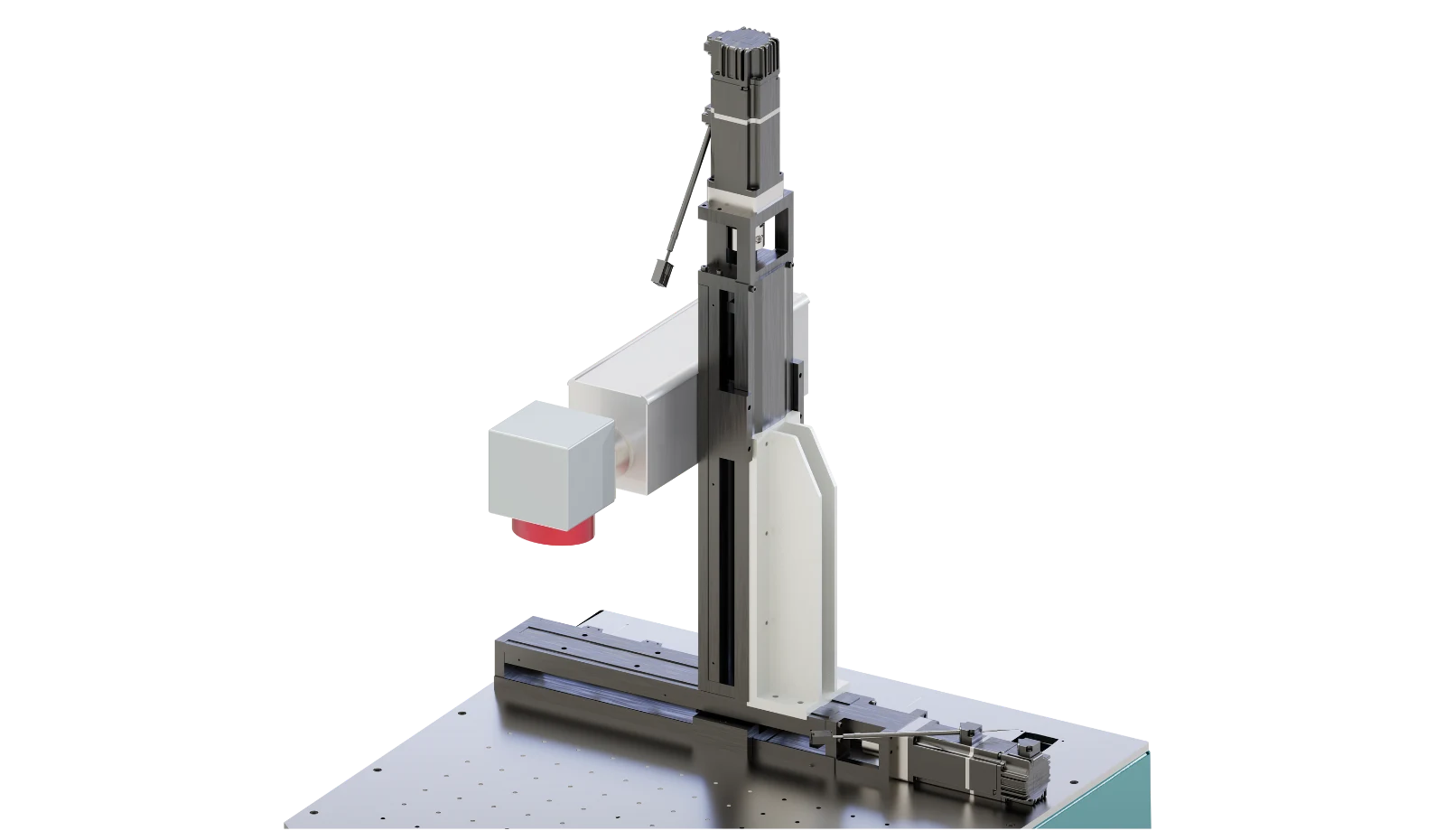

Linear Actuators

- Provides controlled linear motion for positioning parts or adjusting laser head height

- Commonly used for focus control and part alignment

- Integrates easily into standalone and semi-automated workstations

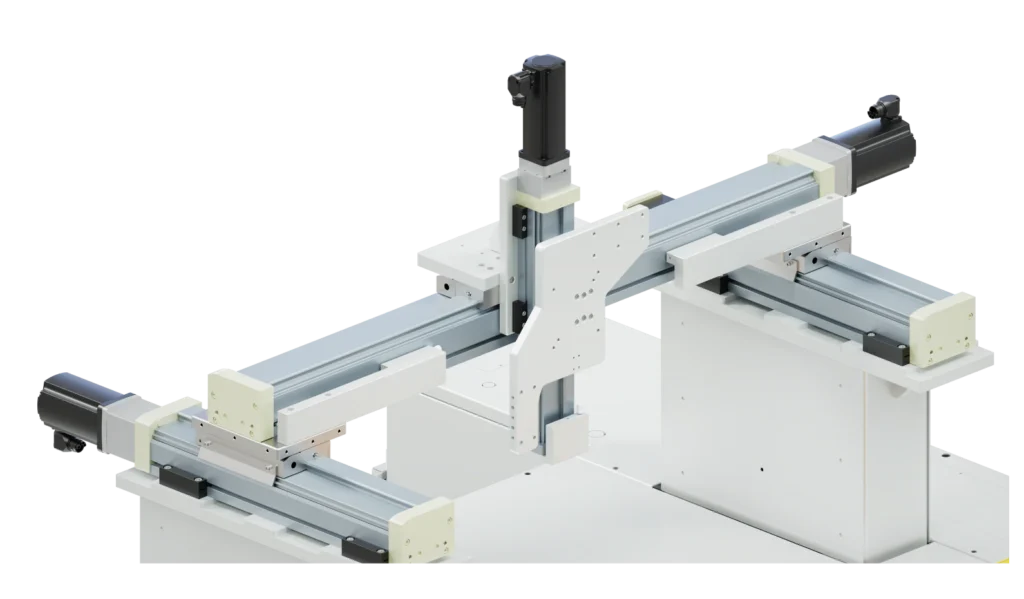

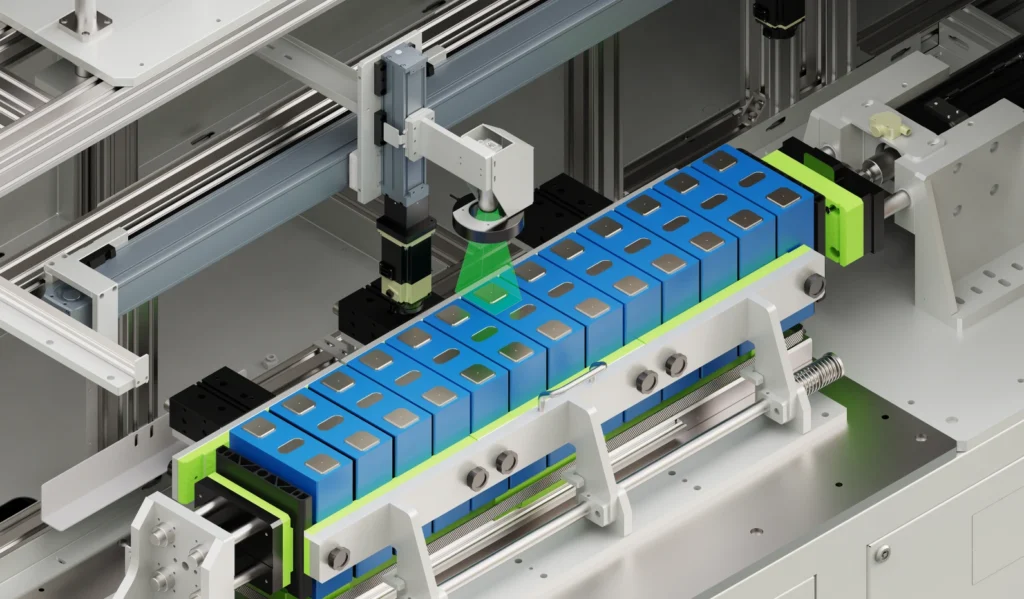

Gantry Systems

- Offers coordinated motion across customised X, Y and Z axes for accurate laser positioning

- Designed for large work envelopes and extended travel ranges

- Suitable for processing battery modules and large-format components

- Ensures stable motion and consistent path accuracy during operation

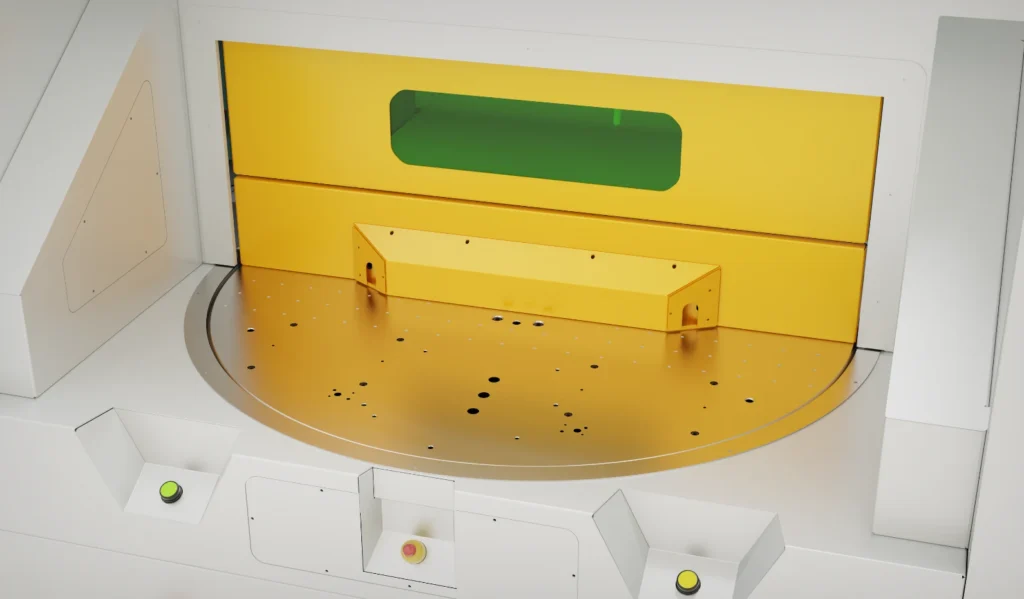

Rotary Indexers

- Uses a rotating table with multiple stations for sequential processing

- Allows parallel operations such as loading, processing, inspection and unloading

- Maintains fixed part orientation at each station

- Well-suited for repetitive, high-volume production environments

Conveyor Systems

- Enables continuous part transfer between process stations

- Supports manual, belt, roller chain and motorized conveyor configurations

- Compatible with manual loading, assisted handling or fully automated lines

- Helps maintain steady throughput with minimal manual intervention

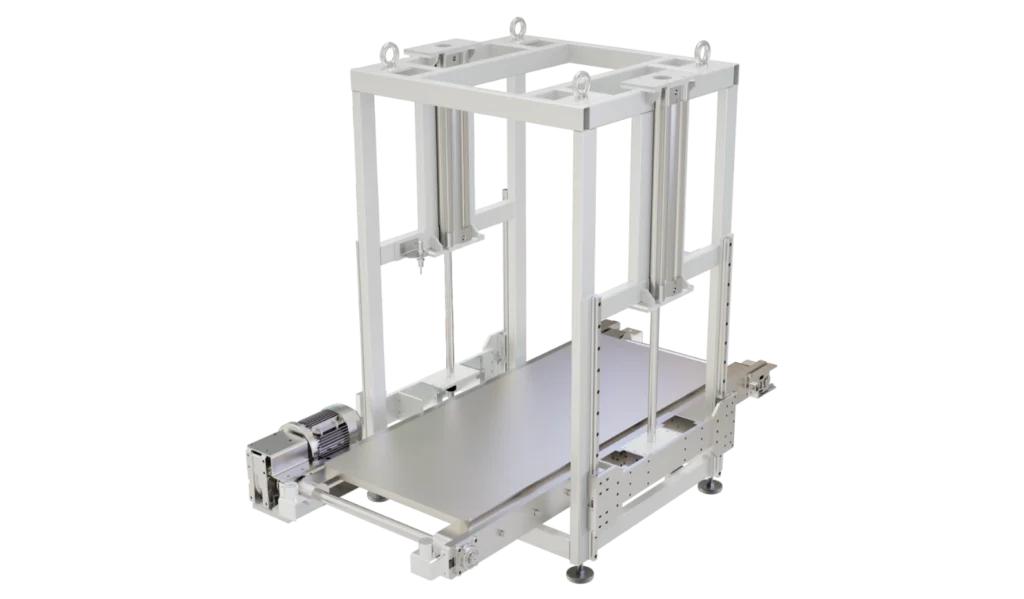

Pallet Exchangers

- Transfers pallets carrying modules or packs between different stations in a battery assembly line

- Enables controlled movement of pallets from one process stage to the next and returns empty or completed pallets for reuse

- Supports organized material flow across welding, inspection, and assembly operations

- Helps maintain stable cycle times in automated and semi-automated battery production

Robotic Integration

- Provides multi-axis motion (6-axis or higher) for complex geometries

- Guides the laser along precise paths across curved, uneven or irregular part profiles

- Reduces manual handling while improving process consistency

- Ideal for heavy and large assemblies

Vision Systems

- Identifies part position and reference features before processing

- Compensates for variation in part placement or orientation with real time correction

- Enables verification tasks such as barcode reading or feature inspection

- Helps maintain precise alignment accuracy while reducing scrap generation and rework

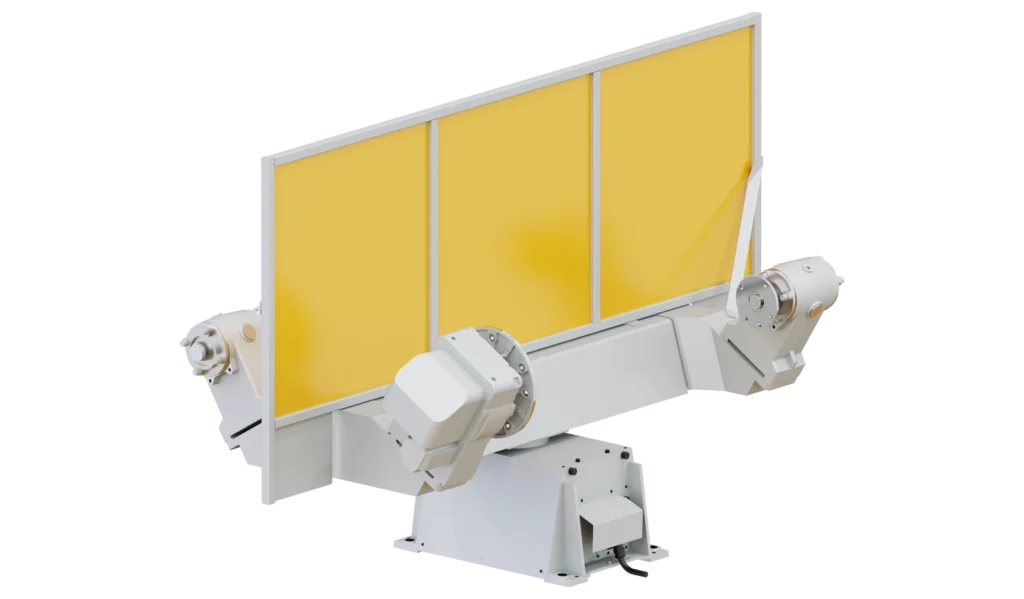

Positioners and Rotary Fixtures for Optimal Weld Access

- Accurate and repeatable positioning of components ensures consistent alignment during laser welding or cutting.

- Smooth and continuous rotary motion enables uniform energy distribution on circular and complex geometries.

- Reduced manual handling improves weld quality, minimizes defects, and increases overall productivity.

- Compatible with cylindrical, domed, and complex-shaped parts used in automotive, battery, and precision manufacturing.

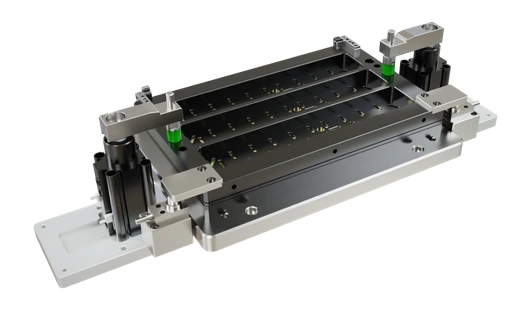

Servo-Controlled Clamping & Press Systems

- Applies uniform pressure during laser welding

- Reduces air gaps and improve weld penetration consistency

Laser Welding Fixtures

- Flexible and adaptable design that supports multiple part geometries, sizes and materials, enabling quick orientation adjustment for accurate weld positioning.

- Designed for controlled clamping to reduce weld-gap variation and heat-induced distortion

- Ensures repeatable joint fit-up, accurate seam positioning and consistent weld penetration across cycles

- Enables faster loading and unloading, reducing cycle time and supporting continuous production.

Together, these automation integrations enable a well-coordinated manufacturing environment where part movement, positioning, verification, and process execution work in sync. Each automation contributes to reducing manual dependency, minimizing process variation, and improving operational reliability. The ability to combine and adapt these systems allows manufacturers to respond efficiently to changing product designs and throughput requirements. This integrated approach supports long-term process stability while simplifying future expansion and seamless upgrades.