Laser Scribing Systems for Fine Feature Definition and Controlled Separation

Laser scribing is a precision laser material processing technique used to define accurate separation paths on brittle, hard and delicate substrates. Unlike full-depth cutting, laser scribing introduces a controlled modification zone along a predefined line, enabling clean and predictable separation in a subsequent breaking or singulation step.

This non-contact process is widely used in ceramic manufacturing, electronics production, semiconductor processing and advanced materials, where dimensional accuracy, edge quality and structural integrity are critical.

The FlashScribe Laser Scribing System by Light Mechanics is engineered for high-precision scribing applications, delivering clean line definition without cracks, chipping or surface damage – ensuring repeatable results in both R&D and high-volume production environments.

How Laser Scribing Works

Laser scribing concentrates focused laser energy along a narrow, controlled path on the substrate surface. This localized interaction alters the material structure and creates a defined weak zone that guides separation accurately and consistently.

Since the process is non-contact and tool-free, there is no mechanical stress on the part. The surrounding material remains unaffected, making laser scribing ideal for thin, fragile and high-value substrates requiring tight tolerances and consistent geometry.

FlashScribe System Design and Technical Capabilities

The FlashScribe platform is designed to maintain accuracy, stability and process consistency during high-speed scribing operations:

- Different Fiber laser configurations from 20W to 450W, adaptable to different ceramic densities and material types

- Precision process heads and galvanometer scanning optics, supporting scan speeds of up to 10,000 mm/sec

- Motorized Z-axis for precise focus control across varying substrate thicknesses

- Customizable laser processing area to cover the biggest substrate.

- Compact and rigid mechanical structure to minimize vibration during fast scanning

Our machine architecture ensures uniform scribe depth and consistent line quality across the entire working field.

FlashScribe Advantages

- Scribe line widths down to 0.05 mm, supporting dense and miniaturized layouts

- Uniform scribe depth across the entire processing area

- Clean edges with minimal debris and waste generation

- Reduced material loss during downstream separation or singulation

- Stable and repeatable performance for development, pilot, and mass production

Laser Drilling Systems for Precision Holes

Laser drilling is a high-accuracy hole-making process used where tight dimensional control, clean edges and repeatability are essential. By removing material through controlled laser pulses, laser drilling enables precise hole formation without mechanical tool contact.

This makes the process ideal for hard, brittle and high-value materials, where conventional drilling methods can cause tool wear, cracking or inconsistent hole quality.

The FlashDrill Laser Drilling Machine from Light Mechanics is designed to deliver consistent hole geometry while maintaining precise control over diameter, depth and positional accuracy.

Laser Drilling Process Fundamentals

Laser drilling focuses laser energy to remove material through controlled ablation. Process parameters such as pulse energy, frequency and focus position are optimized to ensure stable material removal and precise hole geometry.

Due to no physical tool engagement, issues related to tool wear, breakage or mechanical force are completely eliminated – ensuring uniform results over long production runs.

FlashDrill Machine Architecture and Technical Features

FlashDrill systems are engineered for precision, repeatability and industrial reliability:

- Fiber laser sources are selected based on material type, penetration depth and quality of finishing required

- High-precision beam positioning via galvanometer scanners or axis-based motion systems

- Motorized Z-axis for consistent focus across uneven or profiled parts

- Rigid machine structure to maintain alignment during high-speed drilling

Functional and Manufacturing Benefits of Laser Drilling

- Supports blind hole and precision micro-hole drilling, enabling accurate control over hole depth and geometry.

- Smooth hole walls with clean entry and exit edges

- Clean narrow holes with high aspect ratios

- Minimal thermal impact with negligible risk of crack formation

- No tool degradation, ensuring stable quality over extended production cycles

- Automation-ready design, compatible with vision systems and inline manufacturing

Designed for Accuracy, Stability and Manufacturing Consistency

Light Mechanics laser scribing and laser drilling solutions are engineered for industrial manufacturers requiring precise energy control, stable material interaction and repeatable processing in demanding production environments.

Built on rigid machine platforms and supported by advanced beam delivery and motion control systems, these solutions ensure long-term process stability and dimensional consistency. Their modular and configurable design allows seamless integration into standalone workstations or fully automated production lines.

With application-specific process tuning and manufacturing-focused engineering, FlashScribe and FlashDrill systems support scalable production, high-quality output and long-term operational efficiency across electronics, ceramics, semiconductors and advanced industrial applications.

Materials Suitable for Laser Scribing and Drilling

FlashScribe systems support a wide range of brittle and engineered materials, including:

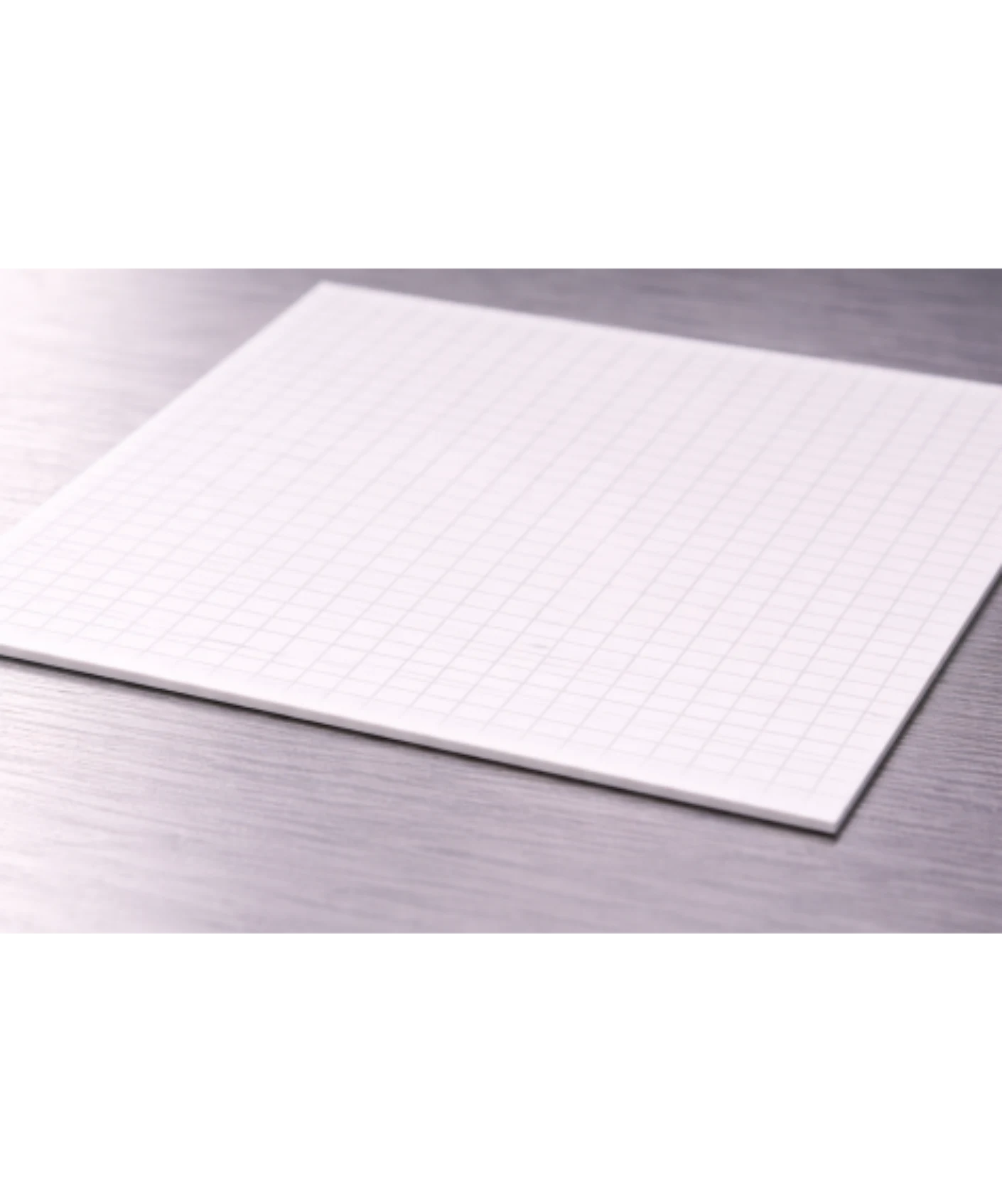

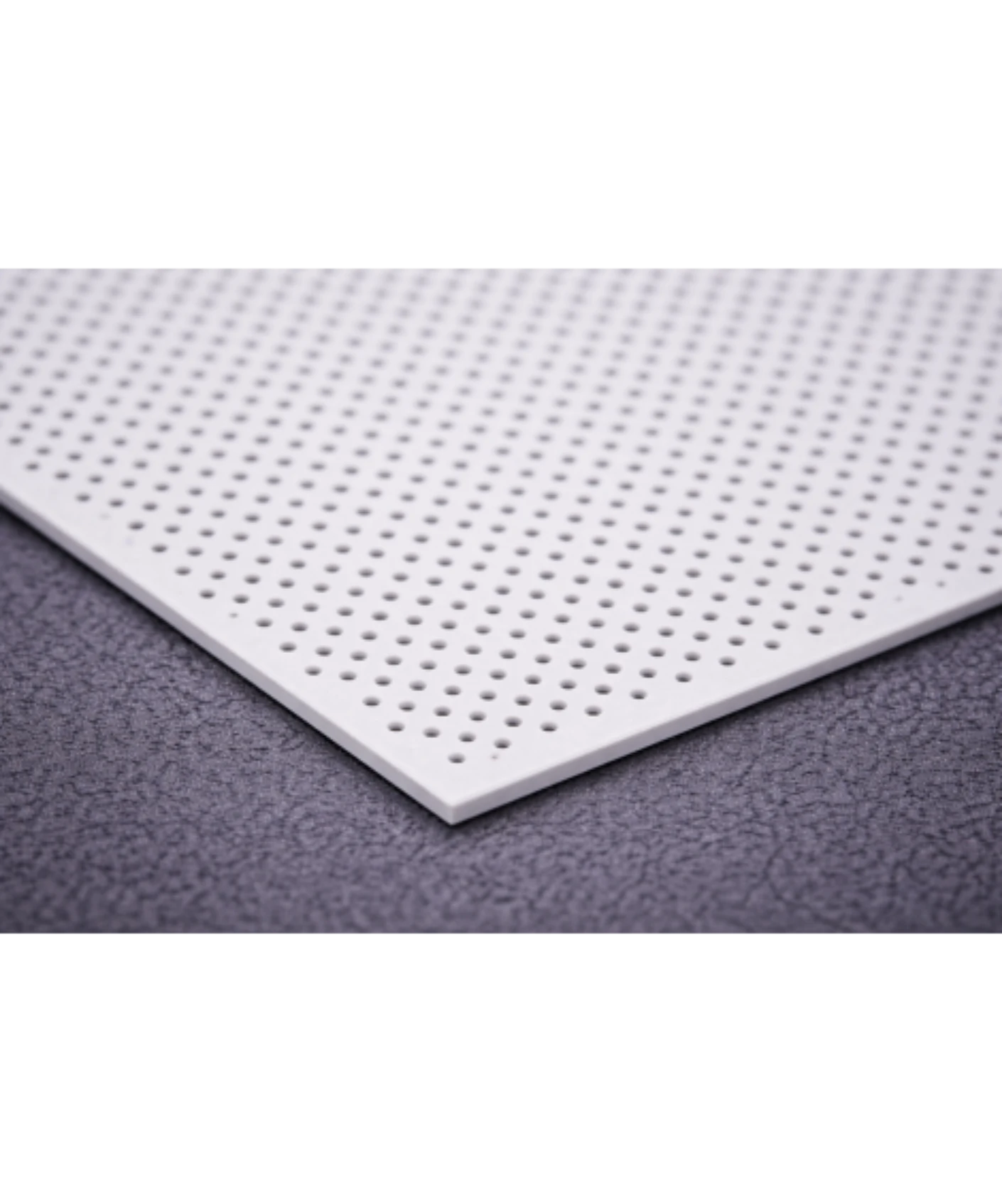

- Ceramic sheets and ceramic substrates

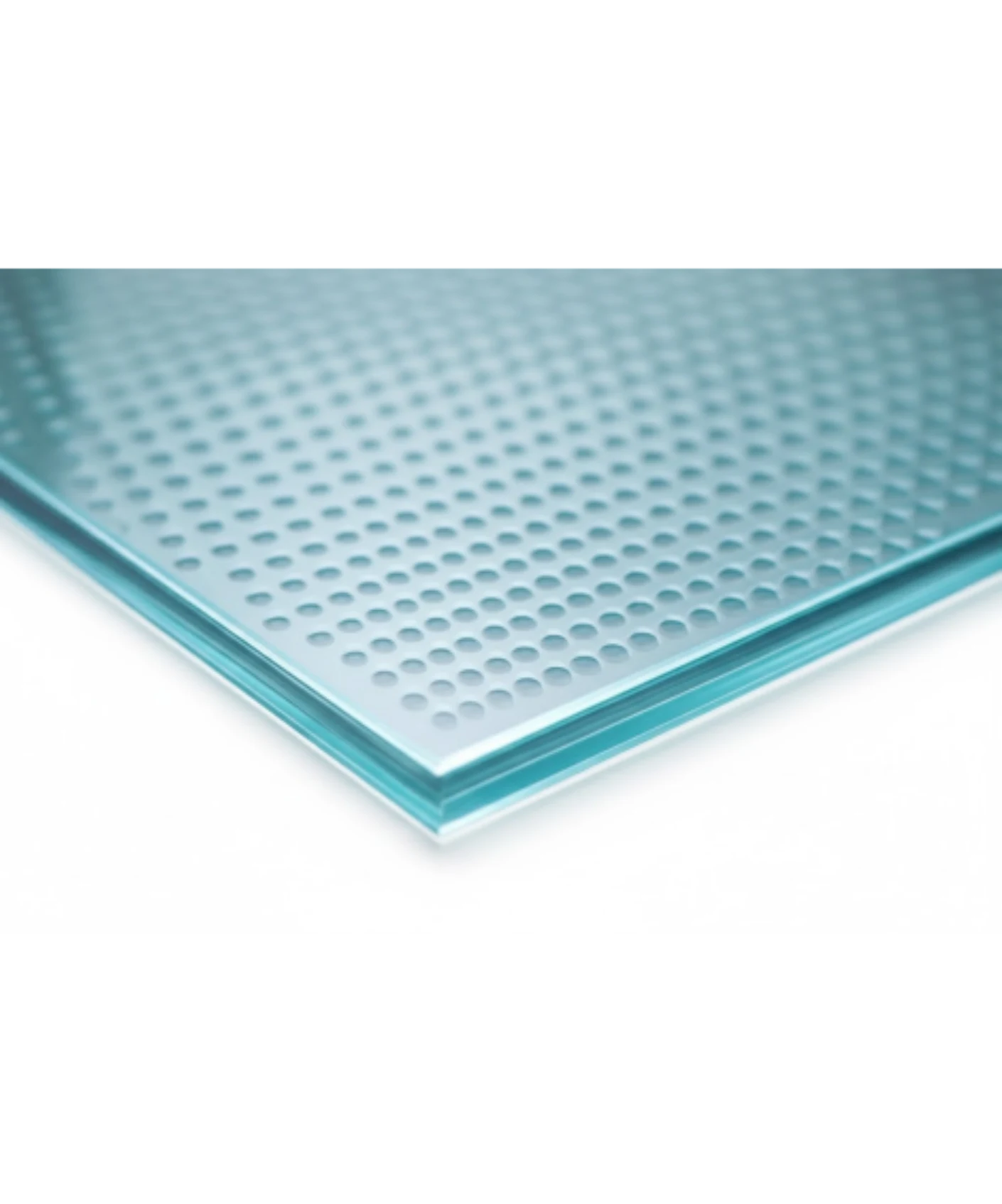

- Glass and coated glass

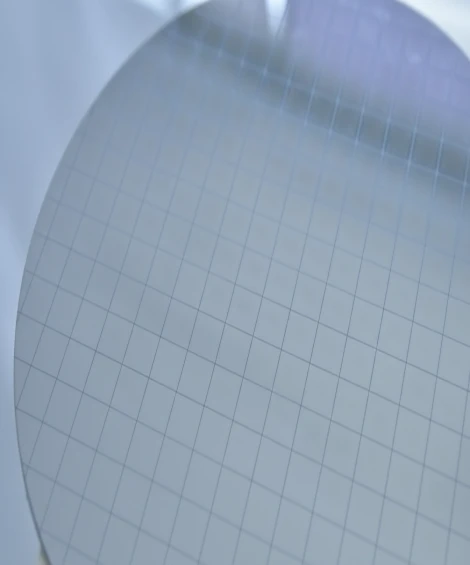

- Semiconductor wafers

- Thin metals and metal-coated surfaces

- Composite and layered materials

- Advanced electronic and brittle substrates