Industrial Laser Marking Machines for Automated Manufacturing & Traceability

Laser marking is a high-precision, non-contact technology used to create permanent, high-contrast identification and traceability marks on metals and non-metals. Industrial laser

marking machines ensure micron-level accuracy, consistent quality and long-term durability,

making them ideal for high-speed automated manufacturing environments.

Light Mechanics laser marking solutions are engineered for automation-ready production,

offering seamless integration into inline systems, robotic cells and Industry 4.0 smart

factories.

Why Choose Laser Marking?

Laser marking delivers reliable identification and traceability across the entire product

lifecycle:

- Permanent and wear-resistant markings

- High marking speeds with consistent quality

- No inks, chemicals or consumables

- Minimal maintenance and low operating cost

- Suitable for high-volume and precision-critical applications

- Fully compatible with Industry 4.0 traceability requirements

Machine Quality & Performance

Light Mechanics laser marking machines are built for continuous industrial use:

- Rigid, industrial-grade construction for vibration-free operation

- Excellent beam quality with repeatability < 2 mrad

- High marking speeds up to 2,500 characters per second

- High-precision optics for sharp text, logos, and machine-readable codes

- Designed for 24/7 production environments

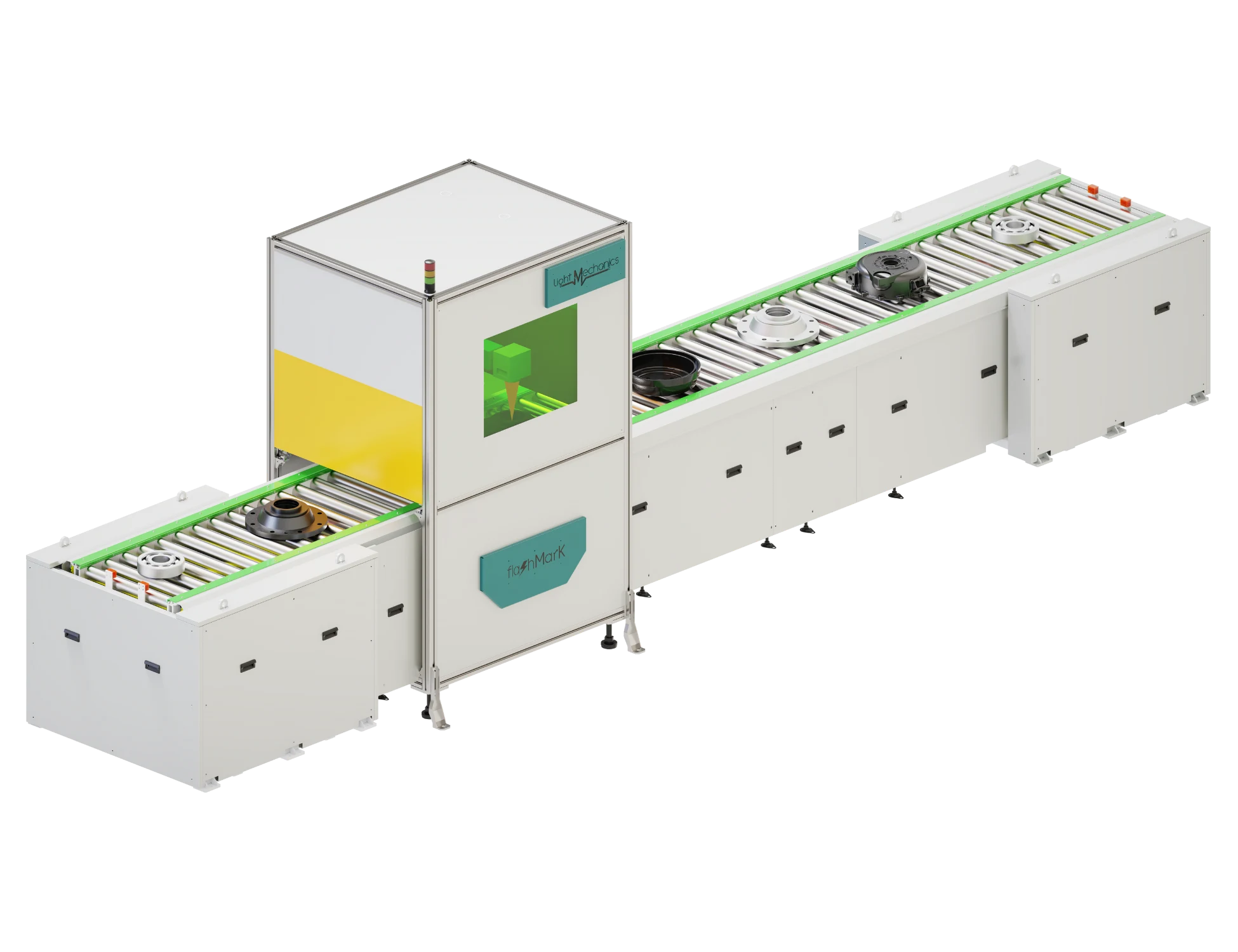

Automation-Focused Laser Marking Solutions - FlashMark Series

The FlashMark series is engineered to support semi-automatic and fully automatic marking

operations, enabling high throughput, reduced manual handling, and zero-error traceability.

FlashMark Product Range

FlashMark Tower

FlashMark Tower is a fully enclosed laser marking workstation engineered for controlled, operator-safe industrial environments. It ensures stable marking quality while supporting continuous production with integrated safety and environmental controls.

- Fully enclosed design ensures operator safety and clean marking conditions

- Integrated safety interlocks and fume extraction enable continuous operation

- Actuator-controlled Z-axis maintains precise focus across varying part heights

FlashMark Tower XL

FlashMark Tower XL is a large-format enclosed laser marking system designed for oversized components and complex assemblies. Its extended work envelope and gantry-based motion allow accurate marking across multiple locations within a single automated cycle.

- Large processing area for oversized parts and assemblies

- Gantry-driven X, Y, and Z axes enable multi-location marking

- High positional accuracy for repeatable marking on large components

FlashMark Shuttle

FlashMark Shuttle is a shuttle-based laser marking system developed for efficient handling of heavy or bulky components. It supports semi-automated operation with recipe-based marking for multi-variant production.

- Shuttle mechanism simplifies loading and unloading of heavy components

- Recipe-based marking ensures consistency across multiple variants

- Increased productivity with reduced operator effort

FlashMark Roto Index

FlashMark Roto Index is a rotary indexing laser marking system optimized for automated marking of identical components. It improves throughput by enabling parallel loading and marking with accurate part positioning.

- Automated rotary indexing for precise and repeatable positioning

- Parallel operations reduce cycle time and improve throughput

- Ideal for medium-volume automated production lines

FlashMark Roto Index XL

FlashMark Roto Index XL is a high-capacity rotary indexing laser marking machine designed for demanding, high-volume manufacturing environments. With multiple configurable stations, it delivers optimized cycle times and consistent traceability.

- Supports 8 to 16 configurable indexing stations

- Optimized cycle times with minimal manual intervention

- Designed for high traceability applications in automotive, battery, and electronics industries

FlashMark Glide

FlashMark Glide is a conveyor-based inline laser marking system built for continuous, high-speed production lines. With Marking-on-the-Fly (MOTF), it enables accurate marking without stopping product movement.

- Inline conveyor-based marking for uninterrupted production

- MOTF capability ensures accurate marking at full line speed

- Seamless integration with MES and automated assembly lines

FlashMark Bench Top

FlashMark Bench Top is a compact, open-frame laser marking solution for flexible, low-volume marking needs. It offers quick setup changes and manual loading, making it ideal for development and job-shop environments.

- Compact and cost-effective marking solution

- Fast setup changes for multiple part variants

- Ideal for R&D labs, tool rooms and job shops

Automation & Industry 4.0 Integration

FlashMark laser marking systems are built for smart manufacturing. They come with:

- Integrated vision systems for part detection, orientation correction and positional accuracy

- Real-time marking quality verification with grade verifier and closed-loop feedback

- Seamless integration with PLC, MES, ERP, and Robotic arms

- Recipe-based marking for multiple part variants

- Complete data logging and production traceability

These capabilities ensure repeatable marking quality, low cycle time, and full production

control.

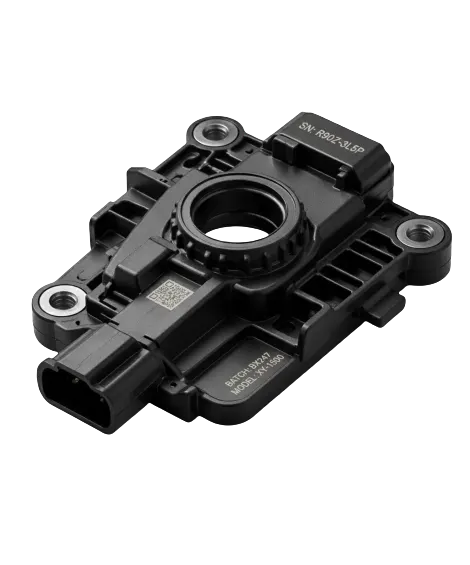

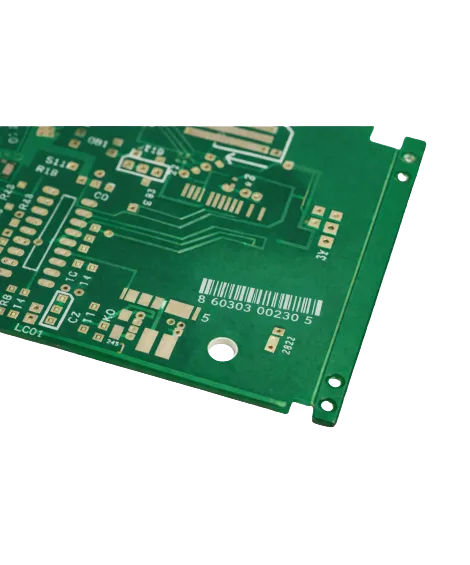

Materials Suitable for Laser Marking

- Metals like stainless steel, aluminum, copper, brass, alloys, etc.

- Plastics and polymers

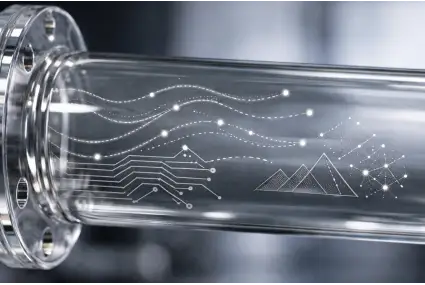

- Glass and ceramics

- Rubber and elastomers

- Coated, anodized, and painted surfaces

- Fabrics and composite materials

Laser Technologies Offered

Fiber Laser

For metals and select plastics

MOPA Fiber Lasers

High-contrast and colour marking for sensitive applications

UV Laser

Ideal for plastics, electronics, medical devices and micro-components

CO₂ Laser

For glass, wood, rubber, fabrics and coated materials

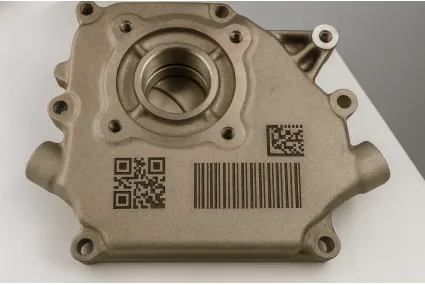

Traceability Starts with Laser Marking

Traceability is one of the most critical demands of today’s manufacturing market.

Maintaining full control over the production chain is no longer optional – It is essential.

Light Mechanics laser marking systems deliver clear, durable and machine-readable markings that remain legible throughout handling, assembly, usage and lasts the entire product lifecycle. Our solutions support both standardized and highly customized manufacturing environments, ensuring compliance, quality and operational excellence.

Light Mechanics laser marking systems deliver clear, durable and machine-readable markings that remain legible throughout handling, assembly, usage and lasts the entire product lifecycle. Our solutions support both standardized and highly customized manufacturing environments, ensuring compliance, quality and operational excellence.

Supported Laser Marking Formats

Alphanumeric text and characters

Barcodes, QR codes, and Data Matrix codes

Logos, brand identification, and symbols

Color Marking

Date codes and time stamps

Serial numbers and unique identification codes

Part numbers, model numbers and batch codes

Custom graphics and patterns

And many more…