Laser Marking enabling Traceability, Compliance & Efficiency across Industries

Laser Marking for Smart Manufacturing: Enabling Traceability, Compliance & Efficiency Across Industries

Introduction

In today’s performance-oriented manufacturing world, international regulations, supply chain

needs and quality check processes require absolute traceability and product identification. Be

it the production of automotive parts, aerospace components, electronics or medical devices,

the capacity to use permanent, legible, and tamper-proof marking is essential.

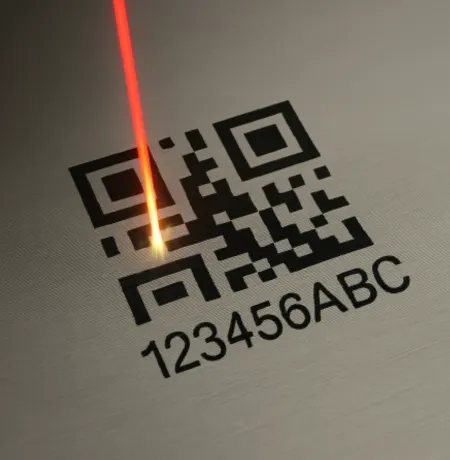

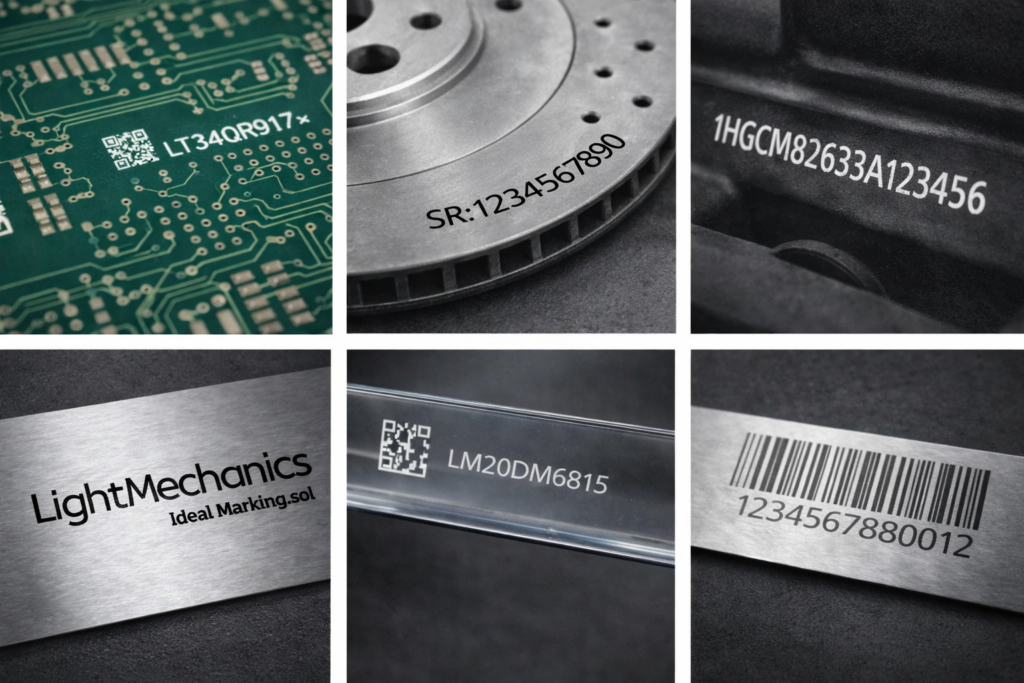

This is where laser marking has emerged as a revolutionary solution. Laser marking is a

contactless operation where a concentrated beam of laser is applied to produce permanent

marks like serial numbers, QR codes, barcodes, logos, etc on various materials. The process

provides ultimate accuracy, speed, and reliability and hence is the best choice in place of

conventional marking methods.

Actual power of laser marking is in the capacity to produce end-to-end traceability, a feature

that’s more vital in industries as they head towards intelligent and regulated production

This growing attention is being led by a number of important factors:

1. Regulatory compliance:

In India the industries for automotive, aerospace, medical equipment, defence and so on are

well regulated and hence complete traceability is demanded by different regulatory bodies.

- Automotive: Part level traceability is mandatory as per AIS (Automotive Industry Standards) and CMVR (Central Motor Vehicles Rules) for quality compliance.

- Medical Devices: Medical Device Rules-2017 prescribes implementation of UDI (Unique Device Identification) for traceability.

- Defence: Defence Ministry and DGQA follow UID (Unique Identification) marking for all defence critical parts.

- Aerospace: The AS9100 must be adhered so that quality and safety can be in balance.

2. Product Recalls and Risk Management

If a faulty product is launched into the market, traceability enables effective recall

management, as the costs and reputational damage for large scale recalls are too high.

Traceability also enables quicker root cause analysis and corrective measures, thus

minimizing the chances of failures.

3. Supply Chain Transparency

Since most components are now being procured on a global or multi-vendor basis,

manufacturers have to ensure supplier compliance and authenticity of parts. Traceability

systems aid the auditing process that is required for quality certifications like ISO 9001 and

IATF 16949 standards in India.

4. Anti-Counterfeiting and Brand Protection

Traceability solutions help identification and authentication of genuine parts, avoiding

utilization of counterfeit items, which is a massive threat in defense, electronics, and

automotive industry. Permanent marking with unique identifiers becomes challenging to

duplicate or alter.

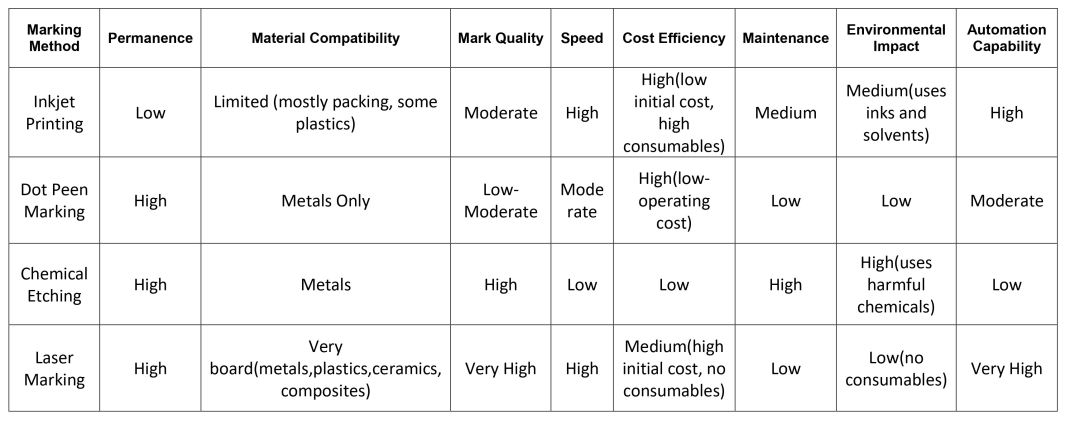

With increasing demand for credible traceability, the right marking technique is vital. Various

marking solutions exist such as inkjet printing, dot peen marking, chemical etching, and

foaming. Therefore, the question that arises is: if there are various marking solutions already

present, why select laser marking?

To determine the most effective marking method it is extremely important to compare the

essential competencies of each process.

Key Parameters Comparison: Laser Marking vs. Traditional Methods

The table indicates that traditional marking techniques are applicable to certain applications,

but they aren’t stable and adaptable. And on the other hand laser marking produces high

resolution, permanent marks without contact or need for consumables, it is compatible with

all materials, and can easily be integrated into an automated production line. These are some

reasons that prove laser marking is a better, faster and more scalable solution for today’s

traceability requirements across each industry.

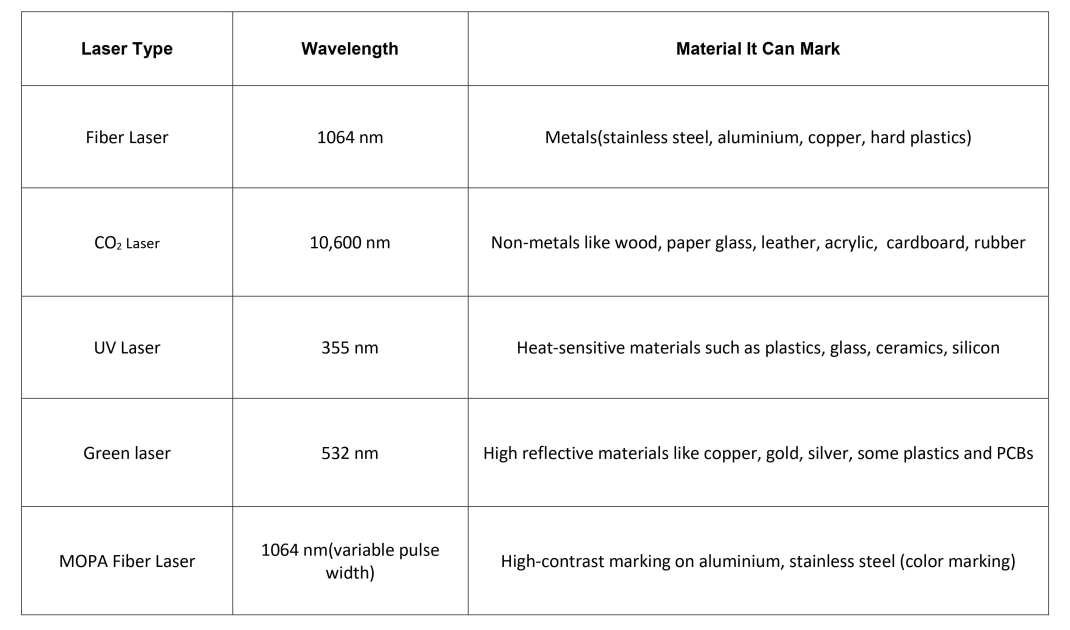

This table emphasizes the strength and versatility of laser marking in a variety of industries.

But its success depends significantly on employing the right kind of laser. There are various

types of lasers, and not every laser works best for every material and every application, it

depends on the laser’s power and wavelength.

Types of Lasers and their Applications in Industrial Marking

Laser marking is a process that is widely used on different materials. It is ideal for metals,

plastics, glass, ceramics, paper, leather as well as heat-sensitive or reflective surfaces. This

enables you to count on it for marking of parts and products in multiple sectors including,

automotive, electronics, aerospace, defense, medical and more guaranteeing clear and

permanent identification.

It can be used for marking on a wide range of material such as metals and non-metals with

several types of information.

Common Data and Identifiers Marked Using Laser Technology

- Alphanumeric Codes

- Barcodes 1D

- QR Codes 2D

- Data matrix Codes

- Serial/Part/Model Numbers

- Company Logos

- Certification Marks (e.g. CE, ISI)

- and many more...

Laser Marking in Different Industries

1. Automotive Industry

- VIN (Vehicle Identification numbers)

- Powertrain, Engine and transmission parts

- Brake components and tyres

- Gearbox and drive shafts

- Airbags and seatbelt components

- Mirrors

2. Aerospace Industry

- Turbine blades and engine components

- Airframe structures

- Fasteners, bolts, and rivets

- Housings and connectors

- Aircraft identification plates

3. Defense Sector

- Weapon components

- Ammunition casings

- Optical and targeting equipment

- Communication devices

- Military vehicle parts

- UID labels as per MoD/DGQA guidelines

- Helmets and tools

4. Electronic components

- PCB’s and semiconductor wafers

- Battery cells and housings

- Sensors and connectors

- Switches, relays, and terminal blocks

Laser Marking Advantages and Limitations

Apart from the flexibility and utility in a variety of applications, laser marking features the

following advantages over conventional marking technologies.

Advantages of Laser Marking

- Permanent & Tamper-Proof: Marks withstand abrasion, solvents, and heat

- High Accuracy & Clarity: Ideal for micro-marking and complex codes

- Non-Contact Process: No damage to fragile components

- Environmentally Friendly: No chemicals or consumables used

- Low Maintenance: Long equipment life and minimal servicing

- Automation-Friendly: Easily integrates into smart factory line

Laser marking has many benefits, such as precision, durability and time efficiency, but it has

certain limitations as well,

- Lasers have high initial costs than conventional marking.

- Improper settings can result in damage on the sensitive parts.

- Colour marking is limited to certain materials and laser sources.

Laser marking is not just an option for part labelling, it’s a key technology for creating wiser,

traceable and more efficient production systems. Its capability to provide permanent and

exact marks on various materials makes it a fundamental part of modern manufacturing.

Laser marking proves out be a pioneering technology in the evolving, automation inclined

and accountable manufacturing.

If you are exploring marking solutions for your production requirements, our team at Light

Mechanics can guide you in selecting and integrating the appropriate laser marking system

for your application.

Connect with us today to discuss your application or schedule a demo with our professionals.

Article By: