Laser Hardening

In modern manufacturing, component failure rarely begins at the core – it starts at the surface.

Component wear, fatigue and surface degradation are the primary reasons why critical parts

fail prematurely. This is where laser hardening technology is redefining surface treatment

by delivering strength exactly where it is needed, without compromising dimensional

accuracy.

Laser hardening is rapidly emerging as the preferred solution for industries that demand durability, precision and repeatable quality.

The Goal of Introducing Laser Hardening

The objective of laser hardening is simple yet powerful:

To increase surface hardness and wear resistance while preserving the original core properties of the component.

By applying controlled, localized heat only to critical zones, laser hardening helps industries

achieve:

- Longer component life

- Higher resistance to wear and fatigue

- Minimal distortion

- Faster processing compared to conventional heat treatment

- Consistent, repeatable results suitable for automation

This makes laser hardening ideal for high-load and high-precision applications where

traditional methods often fall short.

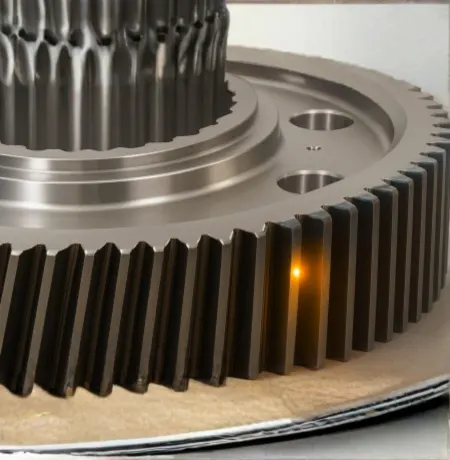

What Is Laser Hardening?

Laser hardening is an advanced surface heat-treatment process in which a focused laser beam

rapidly heats the surface layer of a metal component. Once the laser moves away, the heat

dissipates naturally into the bulk material, causing self-quenching. This rapid heating and

cooling transforms the surface into a martensitic hardened layer, while the core remains

unchanged.

Key Characteristics of Laser Hardening

- Typical hardening depth: 0.5 to 2.5 mm

- No external quenching media required

- Clean, controlled and highly repeatable process

- Suitable for carbon steels, alloy steels, tool steels and automotive-grade steels

Why Laser Hardening Is the Preferred Choice?

Localized Heating for Precision

Laser Hardening heats up only the required surface area which needs to be hardened. This

protects adjacent features and ensures dimensional stability – critical for precision

components.

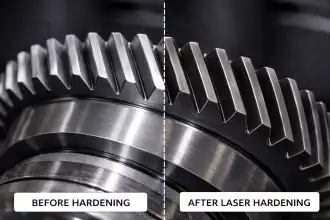

Extremely Low Distortion

Compared to flame or induction hardening, laser hardening produces negligible warpage,

reducing or eliminating post-processing and straightening.

High Surface Hardness

Laser-hardened surfaces achieve excellent hardness levels:

- 42CrMo: up to HRC 55–60+

- Tool steels: up to HRC 58–62+

Automation and Repeatability

The process is easily automated, making it ideal for batch production with consistent quality

across parts.

Applications Supported by Laser Hardening

Laser hardening is widely used in applications where surfaces are exposed to friction, impact,

or cyclic loading.

Gears and Power Transmission

- Spur and helical gears

- Gear teeth strengthening and repair

- Splines and couplings

Automotive Components

- Shafts and axles

- Cam followers and rocker arms

- Crank journals

Industrial Machinery

- Rollers and guide rails

- Wear plates and sliding surfaces

Tooling and Dies

- Punches and moulds

- Cutting edges

- Shear blades

These applications benefit from improved wear resistance while maintaining tight tolerances

and structural integrity.

Why Laser Hardening Makes Sense Today

As industries move toward lighter designs, tighter tolerances, traditional heat-treatment

methods struggle to keep up. Laser hardening offers a modern alternative which is much

cleaner, precise and efficient.

It is particularly effective where:

- Controlled hardness is critical

- Distortion cannot be tolerated

- Only selective areas require strengthening

With laser hardening technology, Light Mechanics is preparing to deliver reliable, high-performance surface treatment solutions for automotive, tooling, industrial machinery and

heavy engineering applications.

Laser hardening is not just about making parts harder – it’s about making them last longer,

perform better and stay accurate with tight tolerances.