Laser Cleaning Systems for Controlled Surface Conditioning

In modern industrial manufacturing, surface condition directly impacts product quality, process stability, and long-term performance. Light Mechanics Laser Cleaning Systems enable precise, non-contact surface conditioning using pulsed laser technology – without chemicals, abrasives or mechanical stress.

Designed for automotive, EV battery manufacturing, aerospace, electronics and other industrial applications, laser cleaning delivers clean, consistent and repeatable surface preparation while preserving base material integrity.

Why Choose Laser Cleaning Systems?

Laser cleaning offers a process-controlled and environmentally friendly alternative to conventional cleaning methods such as chemical baths, sandblasting, and mechanical abrasion.

Key Benefits of Laser Cleaning

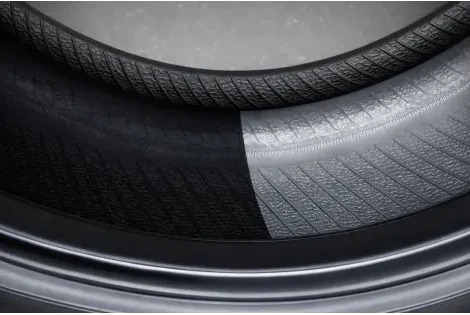

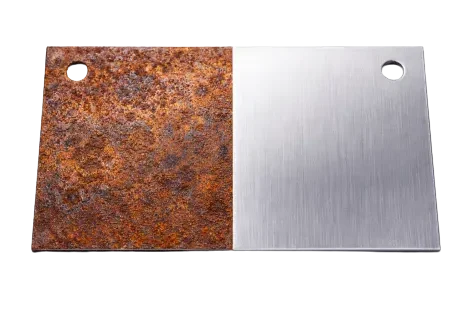

- Precise removal of rust, corrosion, oxides, paints, primers, and coatings

- Effective cleaning of oils, grease, dust, and residual contaminants

- No chemicals, abrasive media, or secondary waste

- Non-contact process that maintains original surface geometry

- Uniform and repeatable surface quality for:

- Pre-weld preparation

- Adhesive bonding

- Coating and painting applications

Laser cleaning offers a process-controlled and environmentally friendly alternative to conventional cleaning methods such as chemical baths, sandblasting, and mechanical abrasion.

Industrial-Grade Machine Design & Cleaning Capability

Light Mechanics laser cleaning machines are engineered for stable performance in demanding production environments.

System Design Highlights

- Rigid industrial machine construction for optics and scanner stability

- Pulsed laser technology for controlled layer-by-layer material removal

- Manual, semi-automated and fully automated loading options

- Optional vision system integration for part detection and alignment

- PLC-based control architecture with recipe-driven programs

- Integrated fume extraction system for safe and clean operation

- Designed for long duty cycles and minimal maintenance

FlashClean Series – Flexible Laser Cleaning Platforms

The FlashClean Series supports a wide range of industrial laser cleaning applications – from standalone workstations to fully automated production lines.

FlashClean Standalone Laser Cleaning System

Fully enclosed system designed for:

- Tool and mould cleaning

- Surface preparation before welding or coating

- Controlled industrial cleaning operations

- Adjustable process parameters with enhanced safety

FlashClean Gantry-Based Laser Cleaning System

Gantry configurations enable laser cleaning of:

- Large, heavy, or oversized components

- Extended work envelopes

- Applications requiring precise, uniform scan paths across wide areas

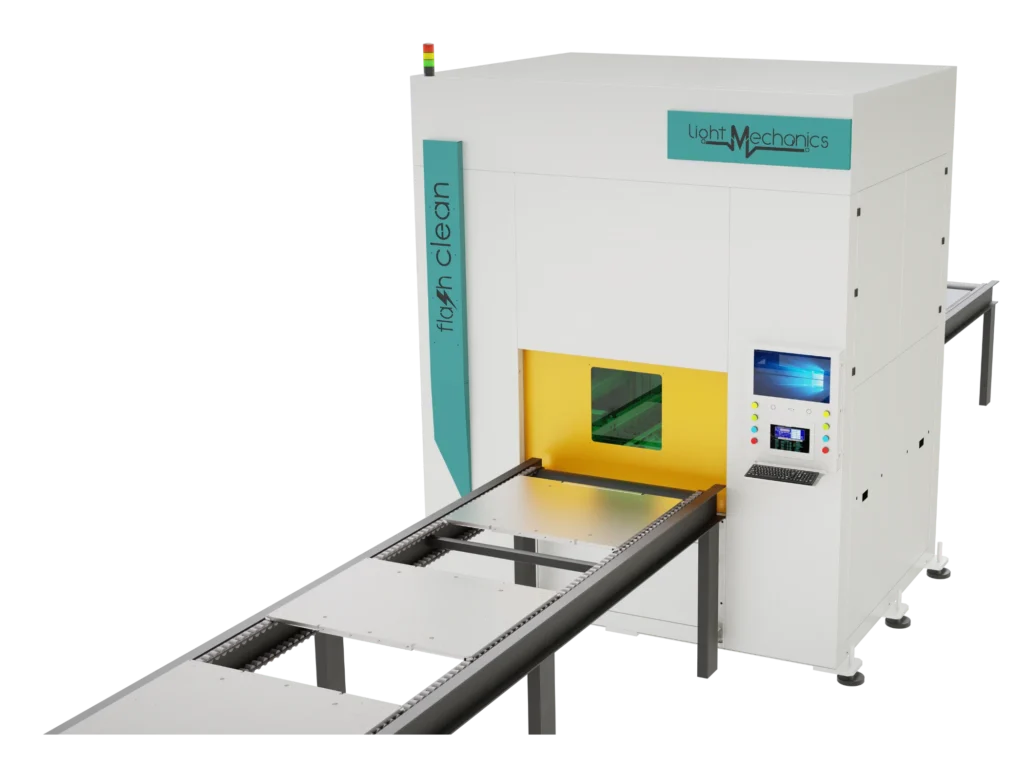

FlashClean Inline Conveyor Laser Cleaning System

Designed for continuous production environments, featuring:

- Conveyor-based material handling

- Stable cycle times

- Seamless integration into automated manufacturing lines

- High throughput with consistent surface quality

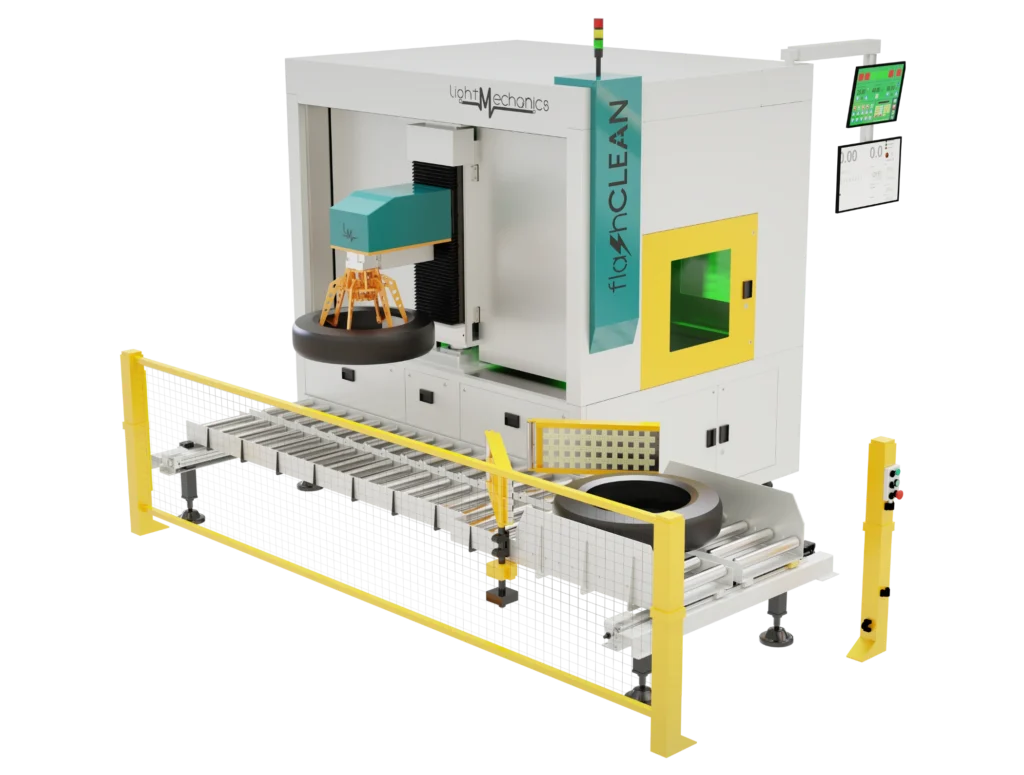

FlashClean Rotary Indexer System

Multi-station rotary indexer platform offering:

- Indexed part positioning

- Sequential laser cleaning operations

- Reduced handling time

- Improved throughput for repetitive cleaning tasks

FlashClean Robotic Laser Cleaning Integration

Robotic integration allows:

- Multi-axis access to complex geometries

- Repeatable cleaning paths

- Fully automated cleaning cells

- Compatibility with leading industrial robotic arms

FlashClean Benchtop Laser Cleaning System

Open-type benchtop configuration ideal for:

- Small to medium-sized components

- Process trials and R&D

- Low-to-medium volume cleaning

- Applications requiring flexibility and quick changeovers

Custom Fixture & Automation Solutions

Light Mechanics provides application-specific fixtures and automation solutions to accommodate diverse component sizes, shapes and handling requirements.

Laser Configuration & Technical Specifications

Our FlashClean Laser Cleaning Systems are configurable to match specific industrial requirements:

- Pulsed laser technology for selective surface removal

- Laser power range: 100W to 1000W

- Optional configurations to match high-throughput applications

- Air-cooled and water-cooled laser options

- Integrated fume extraction and filtration

- Laser safety enclosure compliant with industrial standards

FlashClean Advantages

- Single-pass laser cleaning for effective removal of rust, oxides, coatings, oils, and surface contaminants

- Controlled surface conditioning, including optional texturing and roughness adjustment

- High process stability and repeatability across different materials and component geometries

- Optimized laser parameters and optics for consistent quality and short, predictable cycle times

- Recipe-driven operation enabling fast changeovers between product variants

- Reduced process steps and manual handling, improving productivity and consistency

- Low maintenance, non-contact process resulting in reduced downtime and higher equipment availability

- Environmentally friendly operation with no chemicals, abrasives, or secondary waste

- Cleaner and safer shop-floor environment with integrated fume extraction and laser safety systems

Our system architecture supports easy integration into existing production layouts, helping standardize surface preparation processes and improve overall equipment effectiveness (OEE).

Laser Cleaning Systems - The Future of Industrial Surface Preparation

Laser cleaning represents a fundamental shift in how manufacturers approach surface preparation – combining high performance, environmental responsibility and process flexibility in a single technology. As production lines move toward higher automation, tighter quality control and sustainable operations, laser cleaning has become the preferred solution for modern manufacturing environments.

Light Mechanics delivers complete, production-ready laser cleaning solutions, integrating:

- Industrial laser safety systems

- Advanced fume extraction and filtration

- Automation and robotic integration

- Vision systems for part detection and process consistency

- Custom turnkey solutions developed in collaboration with experienced system integrators

Whether the objective is to improve surface quality, reduce operational costs or scale production with confidence, FlashClean Laser Cleaning Systems provide manufacturers with reliable, repeatable, and future-ready surface conditioning, supporting cleaner, safer and more efficient production lines.