How Light Mechanics Delivers Production-Ready Laser Machines – Right the First Time

From Enquiry to Production Excellence

In today’s high-precision manufacturing environment, laser machines are no longer just tools

on the shop floor – they are strategic assets that define product quality, throughput and

competitiveness.

Whether it’s welding, cutting, marking, drilling or surface treatment, manufacturers demand

laser systems that deliver high speed, absolute repeatability, and zero compromise on quality.

Achieving this consistently requires more than powerful hardware – it demands a deeply

validated process and a quality-first engineering approach.

At Light Mechanics, we don’t just manufacture laser machines.

We deliver validated, production-ready laser solutions – engineered to perform reliably from day one and throughout their lifecycle.

We deliver validated, production-ready laser solutions – engineered to perform reliably from day one and throughout their lifecycle.

This is how we do it.

Quality Is Not Inspected. It Is Engineered.

Our philosophy is simple:

True quality is built into the process, not checked at the end.

That’s why every project at Light Mechanics follows a structured, end-to-end execution

model. Starting from the first enquiry to production handover, we ensure our customers

receive machines that are stable, scalable and future-proof.

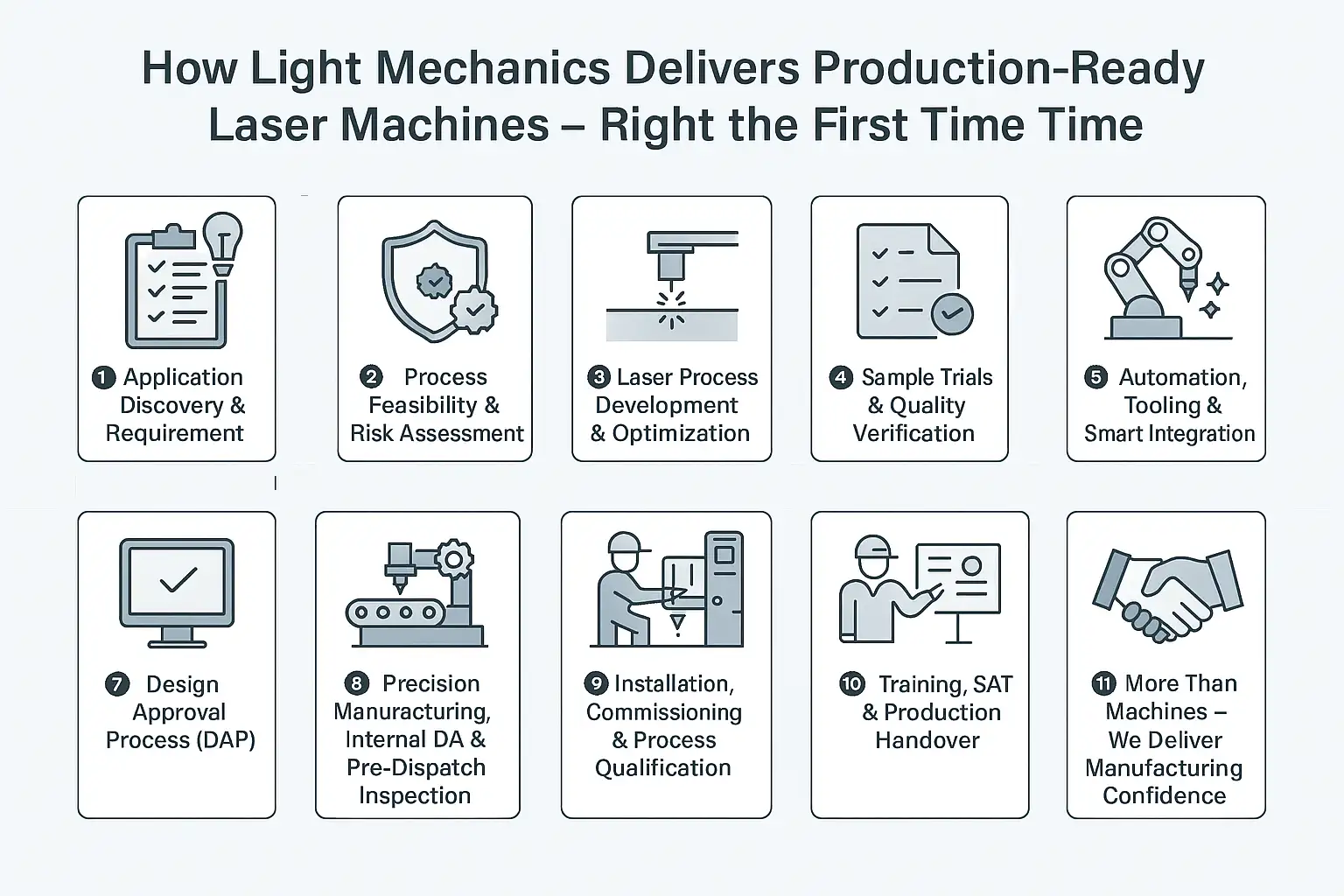

Our End-to-End Laser Project Journey

1. Application Discovery & Requirement Alignment

Every successful laser solution starts with understanding your application in depth.

We collaborate closely with your engineering and production teams to define:

- Material, thickness and joint/feature geometry

- Quality expectations - mechanical, electrical and cosmetic

- Production targets, cycle time and scalability

- Automation, safety and compliance needs

This upfront clarity allows us to design the right solution from the beginning, avoiding costly

changes later.

2. Process Feasibility & Risk Assessment

Before committing to a solution, our experts evaluate:

- Technical feasibility of the laser process

- Metallurgical and thermal risks

- Automation and fixturing challenges

- Safety and compliance considerations

This step ensures no assumptions, no surprises – only proven engineering decisions.

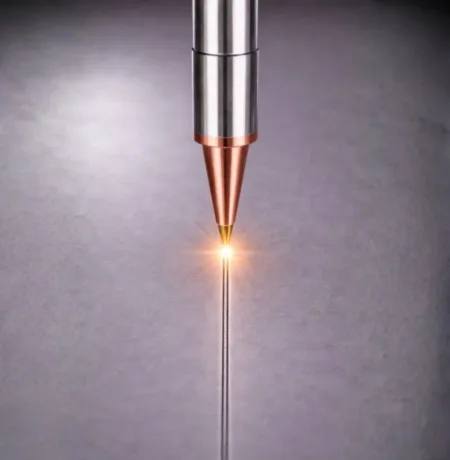

3. Laser Process Development & Optimization

Using customer samples, we develop a robust and repeatable laser process by optimizing:

- Laser type and power

- Optics and beam delivery

- Speed, pulse characteristics and focus position

- Shielding gas parameters (where applicable)

The result is a wide, stable process window designed for real-world production – not just lab

success.

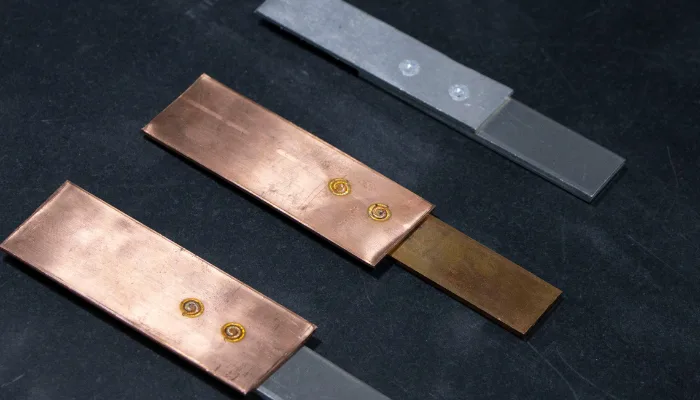

4. Sample Trials & Quality Verification

Our in-house sample trials validate that the process meets real manufacturing expectations:

- Weld integrity, penetration and strength

- Edge quality and heat-affected zone control

- Marking grade, contrast, readability and permanence

Testing may include destructive and non-destructive methods such as tensile tests, crosssections and visual inspections – ensuring measurable confidence before scaling up.

5. Repeatability & Production Capability Validation

A laser process is only valuable if it performs consistently at scale.

We validate:

- Repeatability across batches, shifts and operators

- Long-run stability

- Cp (process capability) and Cpk (process capability index) values wherever applicable

This guarantees that your laser system is ready for continuous production, not just prototype

success.

6. Automation, Tooling & Smart Integration

Laser performance depends on the ecosystem around it.

Our validation extends to:

- Automation and cycle-time optimization

- Precision fixturing and part handling

- Vision systems, seam tracking and inline weld monitoring

- PLC logic, safety interlocks and HMI workflows

Every system is designed to maximize uptime, accuracy and operator confidence.

7. Design Approval Process (DAP): Confidence Before Commitment

Once the solution is finalized, we conduct a Design Approval Process (DAP) with the

customer.

This structured review ensures:

- The machine is fit for the application

- All quality, safety and regulatory requirements are addressed

- Risks are identified and mitigated

- The design is ready for execution

It acts as a gate between design and execution, ensuring the laser machine will meet

application, quality, safety and compliance requirements by design, and not by correction

later.

8. Precision Manufacturing, Internal QA & Pre-Dispatch Inspection

Every laser machine is built under strict internal QA controls and undergoes a comprehensive

Pre-Dispatch Inspection (PDI) to confirm:

- Build accuracy as per approved design

- Functional and safety compliance

- Readiness for shipment, installation, and acceptance

Only machines that meet 100% of defined criteria leave our facility.

10. Installation, Commissioning & Process Qualification

At your site, our engineers:

- Install and qualify the machine (IQ)

- Perform commissioning and functional verification

- Conduct process trials under real production conditions (OQ / PQ)

This helps in full qualification of the machine at site, performing reliably under real

production conditions and ready for controlled scale-up without operational risk.

11. Training, SAT & Production Handover

- Operator and maintenance training

- Site Acceptance Testing (SAT)

- Complete documentation and support handover

- Warranty and service support begin

- Machine is released for production

At this stage the machine is formally accepted, your teams are fully enabled, and the laser

system is confidently released for uninterrupted production.

More Than Machines – We Deliver Manufacturing Confidence

At Light Mechanics, we believe that successful laser manufacturing is not just about machine

delivery. It’s about process ownership by combining:

- Structured process validation

- Robust quality assurance

- Thoughtful automation design

- Customer-centric execution

High-precision manufacturing leaves no room for uncertainty. Choosing the right laser

machine is not just about specifications – it’s about process understanding, validation and

long-term reliability.

At Light Mechanics, we partner with you from the very first enquiry to full-scale production,

ensuring every laser solution is engineered, validated and delivered with confidence.

Have a laser application to evaluate or a production challenge to solve?

Reach out to us today to discuss your requirement, share samples and explore how our

validated laser solutions can support your manufacturing goals.

Let’s engineer precision – right from the first step.

Article By:

Shipra Sinha

(Director – Sales & Marketing, Light Mechanics)

LinkedIn: www.linkedin.com/in/shipra-sinha-50179961

(Director – Sales & Marketing, Light Mechanics)

LinkedIn: www.linkedin.com/in/shipra-sinha-50179961