Laser Applications for Electronics & Semiconductors

Semiconductors are the foundation of modern electronic devices and their manufacturing

demands extreme precision, cleanliness and process stability. As device sizes continue to

shrink and functional complexity increases, manufacturers require processes capable of

delivering micron-level accuracy, high repeatability and contamination-free operation.

Laser technology plays a critical role in electronics and semiconductor manufacturing due to

its thin, precise and highly controllable energy delivery. Laser-based processes are widely

used for cutting, marking, coating removal and welding, enabling manufacturers to process

delicate and complex components without physical contact, tool wear or deformation.

Laser processing has become a core enabling technology in semiconductor production,

offering digitally controlled, non-contact operation that supports high-throughput

manufacturing while meeting strict quality, reliability and yield requirements.

Light Mechanics delivers application-driven laser solutions tailored for electronics and

semiconductor manufacturing, supporting scalable production and consistent high-yield

performance across advanced electronic and semiconductor applications.

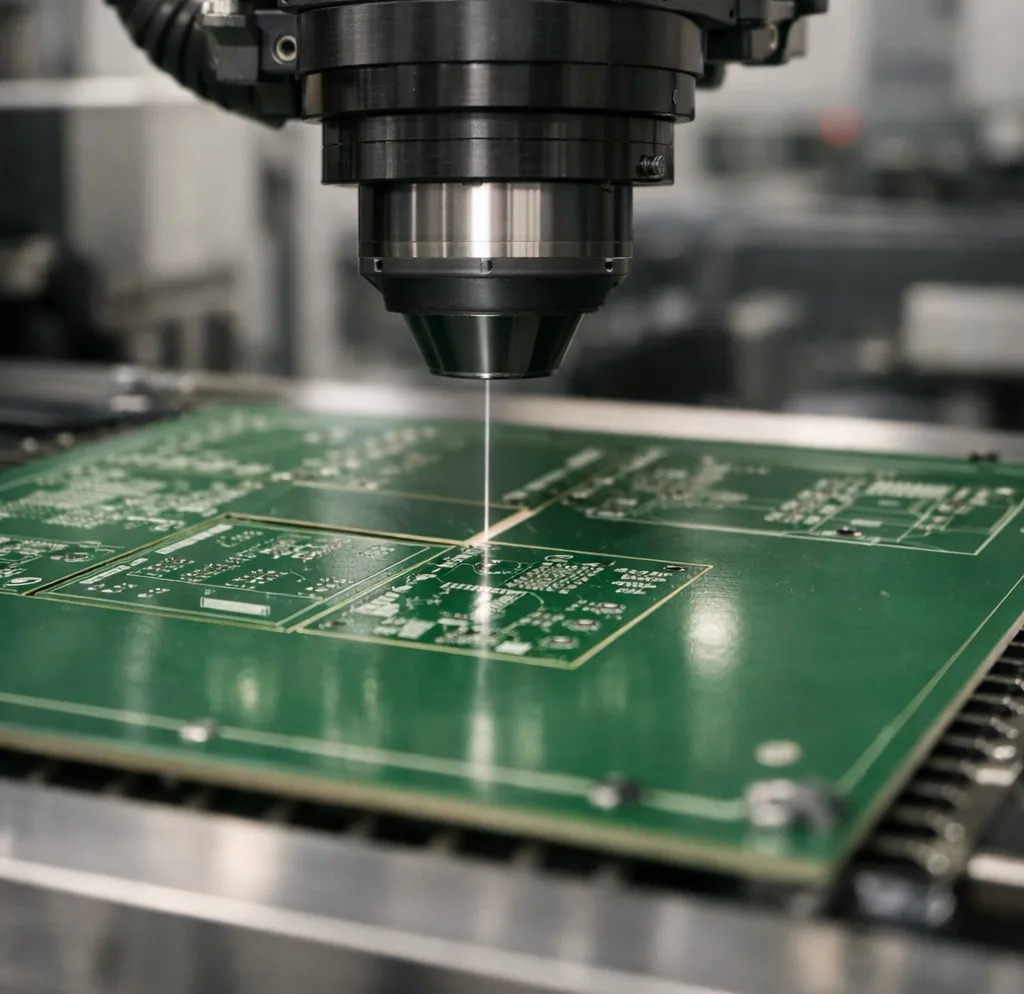

PCB & Wafer Laser Marking

Application Demand

Printed circuit boards and semiconductor wafers require permanent, high-resolution

identification for traceability, quality control and process tracking. Markings must be legible

at micro-scale, applied without physical contact and must not damage sensitive circuits,

layers or device structures.

What Laser Enables

Laser marking enables precise, permanent and non-contact identification directly on PCBs

and wafers with fine spot sizes, stable pulse energy and no mechanical stress. It supports

high-density data matrix codes, serial numbers and logos with excellent contrast while

preserving electrical integrity. The process is fast, repeatable and fully compatible with inline

semiconductor and electronics production.

PCB and Wafer Cutting

Application Demand

Printed circuit boards and semiconductor wafers require high-precision separation without

inducing burrs, mechanical stress or micro-cracks that can reduce yield and long-term

reliability. As substrates become thinner and more complex, cutting processes must protect

micro-scale features, multilayer structures and edge integrity.

What Laser Enables

Laser cutting provides clean, burr-free and non-contact separation of PCBs and wafers with

controlled energy input and minimal heat-affected zones. The process prevents mechanical

stress and micro-cracking, ensuring consistent edge quality, improved yield and compatibility

with automated, high-volume electronics and semiconductor production.

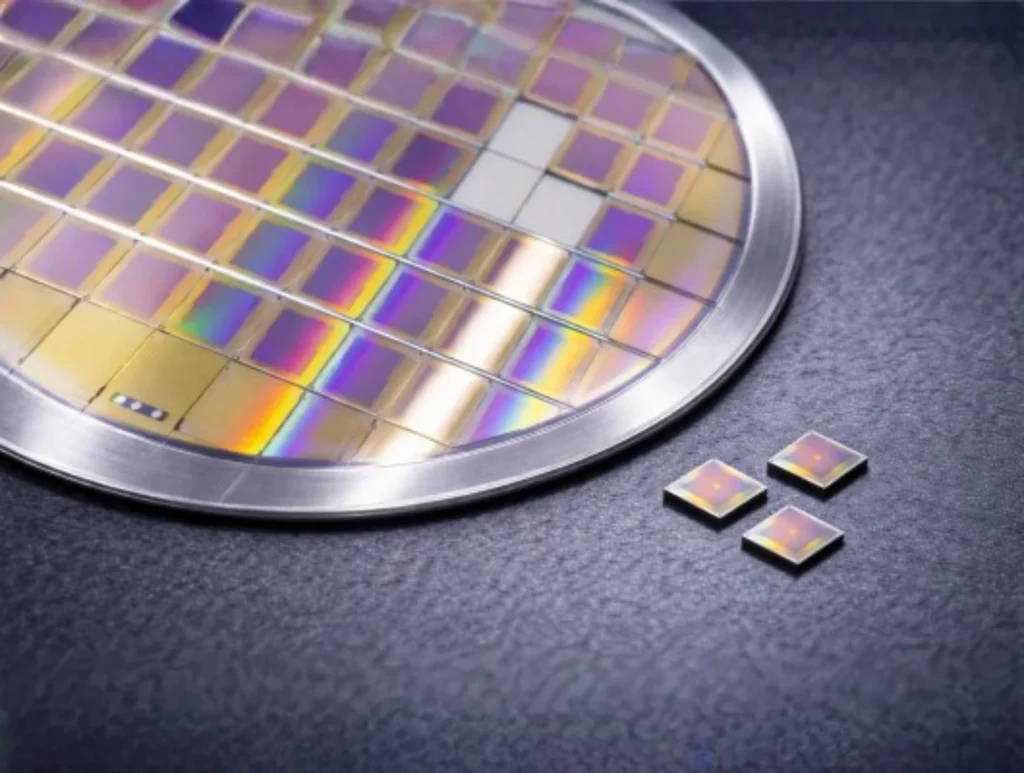

Wafer Scribing and Dicing

Application Demand

Semiconductor wafers require precise and controlled singulation to produce individual dies

without chipping, cracking or edge damage. As device dimensions shrink and packaging

technologies advance, maintaining die strength, yield and edge quality becomes increasingly

critical.

What Laser Enables

Ultrashort and solid-state lasers enables narrow kerf widths and clean, well-defined scribe

lines with minimal thermal impact on surrounding material. The process reduces chipping,

improves die strength and supports high-yield singulation for advanced semiconductor and

microelectronics packaging.

Notebook Audio Hole Drilling

Application Demand

Speaker and microphone openings in notebooks and consumer electronics require precisely

sized and uniformly distributed micro-holes to ensure consistent acoustic performance and

high cosmetic quality. Hole geometry, edge quality and repeatability are critical, as

inconsistencies can affect sound output, appearance and assembly yield.

What Laser Enables

Laser drilling enables highly controlled micro-hole formation with precise diameter and taper

control and burr-free edges. The non-contact process ensures excellent repeatability, clean

aesthetics and consistent acoustic performance while supporting high-speed, automated

production for consumer electronics.

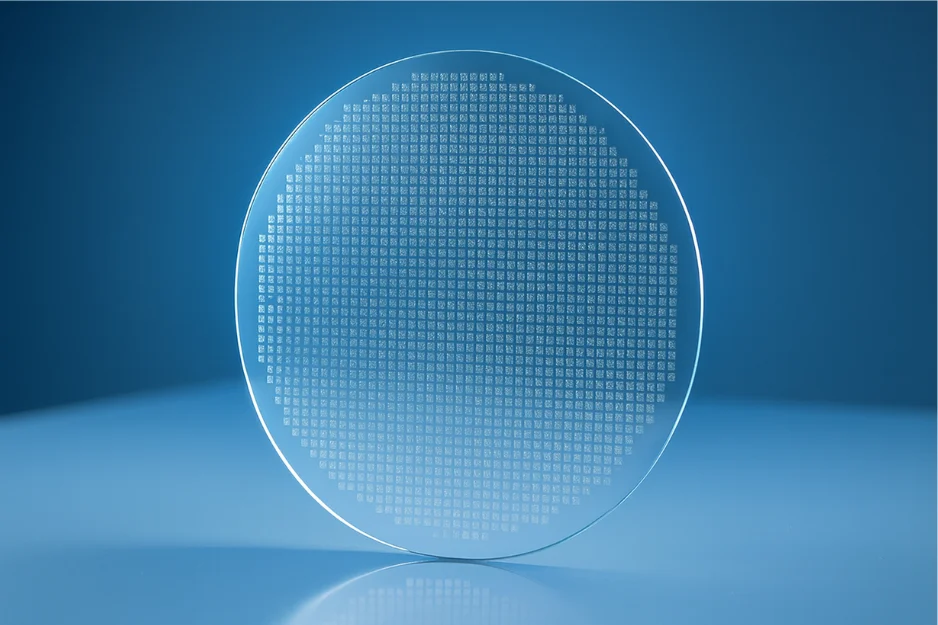

Glass Cutting for Consumer Electronics

Application Demand

Across consumer electronics, optics, automotive and advanced packaging, glass has become a critical material due to its flatness, thermal stability, chemical resistance and optical performance. From cover glass, camera windows, UTG ultra thin substrates and LCD panels to packaging wafers, interposers and rearview mirrors, manufacturers require precise, high throughput processing with tight tolerances. As devices become thinner, coated and more complex, traditional mechanical methods struggle to meet requirements for defect free edges, crack free vias and scalable production.

What Laser Enables

Ultrashort pulse laser technology provides non contact, selective and damage free processing of brittle materials. It enables cutting, drilling and structuring with superior edge quality, minimal thermal impact and repeatable results – even on chemically strengthened or coated substrates. Lasers support complex contours, free form designs and ultra thin glass processing, while reducing particle generation. Optimized material flow in laser systems allows manufacturers to scale efficiently from small batches to mass production, reducing per-component costs while meeting the stringent demands of modern electronics packaging.

Why Choose Light Mechanics

Light Mechanics delivers precision laser machines specifically engineered for electronics and

semiconductor manufacturing. Our systems provide micron-level accuracy, high

repeatability and non-contact processing, ensuring zero-defect production and protection of

delicate components.

With expertise in PCB and wafer marking, cutting, scribing, dicing and micro-drilling, we

enable high-throughput, automated production while maintaining edge integrity, device

reliability and process consistency. Our solutions minimize thermal impact, eliminate

consumables and support inline, scalable manufacturing, helping electronics and

semiconductor manufacturers achieve superior yield, traceability and quality compliance in

increasingly complex, miniaturized devices.