Laser Applications for Defence & Aerospace

Defence and aerospace manufacturing operates under some of the most demanding

conditions applicable in any industry. Components must meet extreme standards for

precision, reliability, weight reduction and traceability, while performing under high stress,

temperature variation and harsh environments. Manufacturing processes must deliver zero-defect quality, repeatability and full compliance with stringent aerospace and defence

regulations.

Laser-based manufacturing has become a critical enabler across airframes, propulsion

systems, avionics, electronics and defence hardware. Its ability to deliver controlled, non-contact energy with high accuracy and digital repeatability makes laser processing ideally

suited for both aerospace-grade materials and mission-critical components.

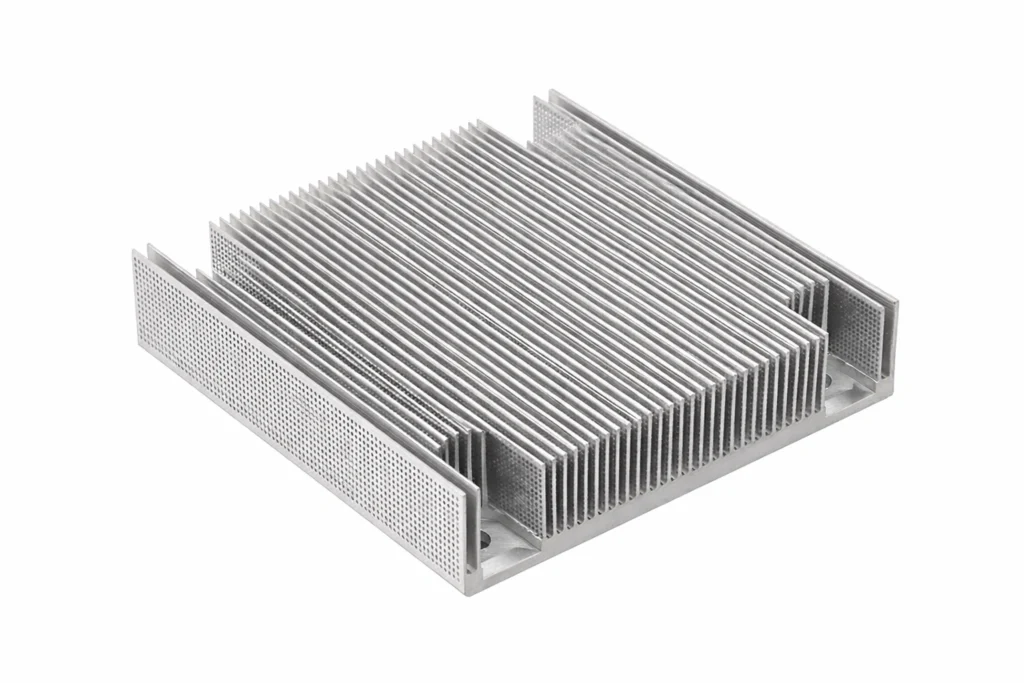

Laser Micro-Machining for Structural Components, Turbine Blades and Electronics

Application Demand

Aerospace-grade metals, composites and electronic components require precise drilling,

scribing, cutting and marking with tight tolerances. Surface integrity, minimal thermal impact

and micron-level accuracy are critical for fatigue resistance, component reliability and

electrical performance. The applications include structural parts, turbine blades, cooling

channels, connectors, PCBs and sensors.

What Laser Enables

Laser micro-machining provides high-precision, non-contact material processing with

minimal heat-affected zones. It ensures repeatable accuracy, preserves material properties

and supports automated production across structural, thermal and electronic components.

Complex geometries, micron-scale features and tight tolerances are achieved without

mechanical stress or substrate damage.

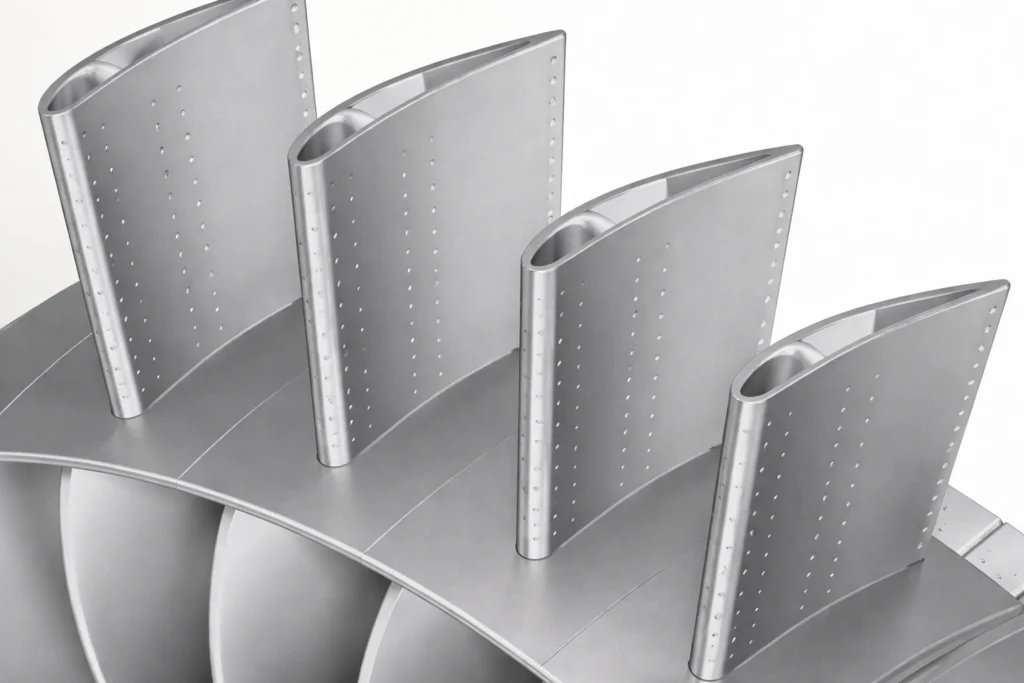

Laser Drilling for Cooling Channels

Application Demand

Turbine blades and combustor components require micron-scale cooling channels to manage

extreme temperatures and thermal stresses. Accuracy and uniformity are critical for airflow

efficiency, performance and component longevity.

What Laser Enables

Laser drilling delivers precise, repeatable micro-holes with controlled diameter, taper and

spacing. The non-contact process ensures minimal HAZ, preserves structural integrity and

enables optimized thermal management for high-performance turbine components.

Laser Marking for Turbine Components and Brake Disks

Application Demand

High-temperature aerospace and defence parts require durable, high-contrast identification

for traceability, maintenance and lifecycle management. Markings must withstand extreme

temperatures, vibrations and operational stress.

What Laser Enables

Laser marking provides permanent, heat-resistant and climate resistant identifiers on metals

and composites. It ensures readability under harsh conditions, supports traceability and

enables maintenance compliance without damaging the base material.

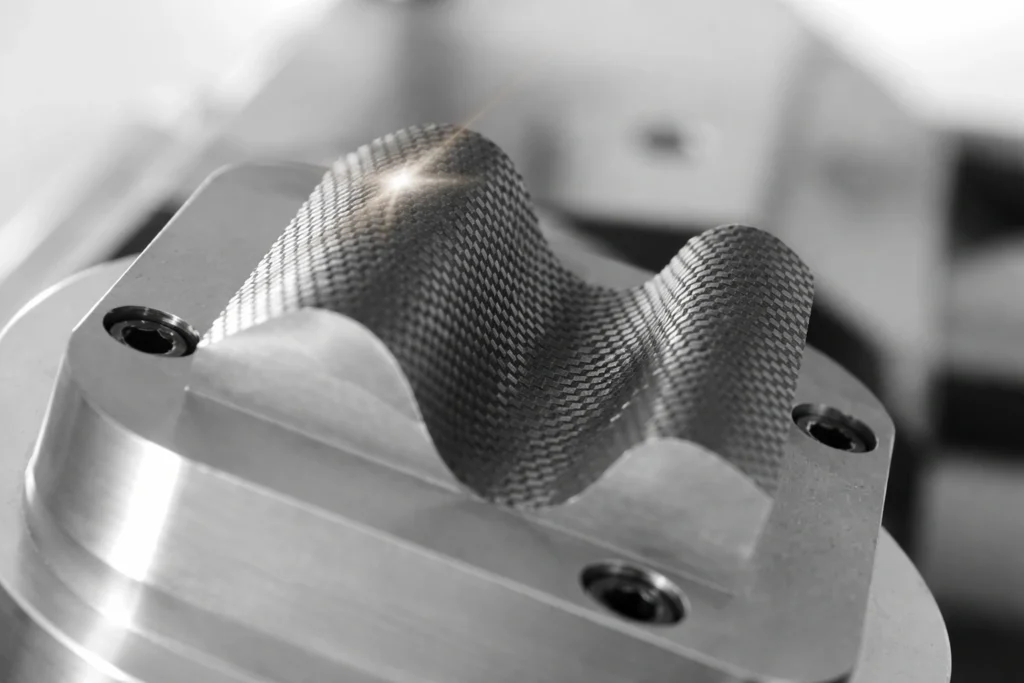

Laser Texturing & Surface Preparation

Application Demand

Aerospace components often require controlled surface roughness to enhance adhesion for

thermal spray coatings, bonding and painting. Inconsistent surface preparation tends to

reduce bond strength and coating longevity.

What Laser Enables

Laser texturing creates precise, repeatable micro and macro-structures to improve coating

adhesion, bonding strength and heat transfer. The process is non-contact, chemical-free and

compatible with high-volume production, enhancing performance and durability of coatings

and bonded components.

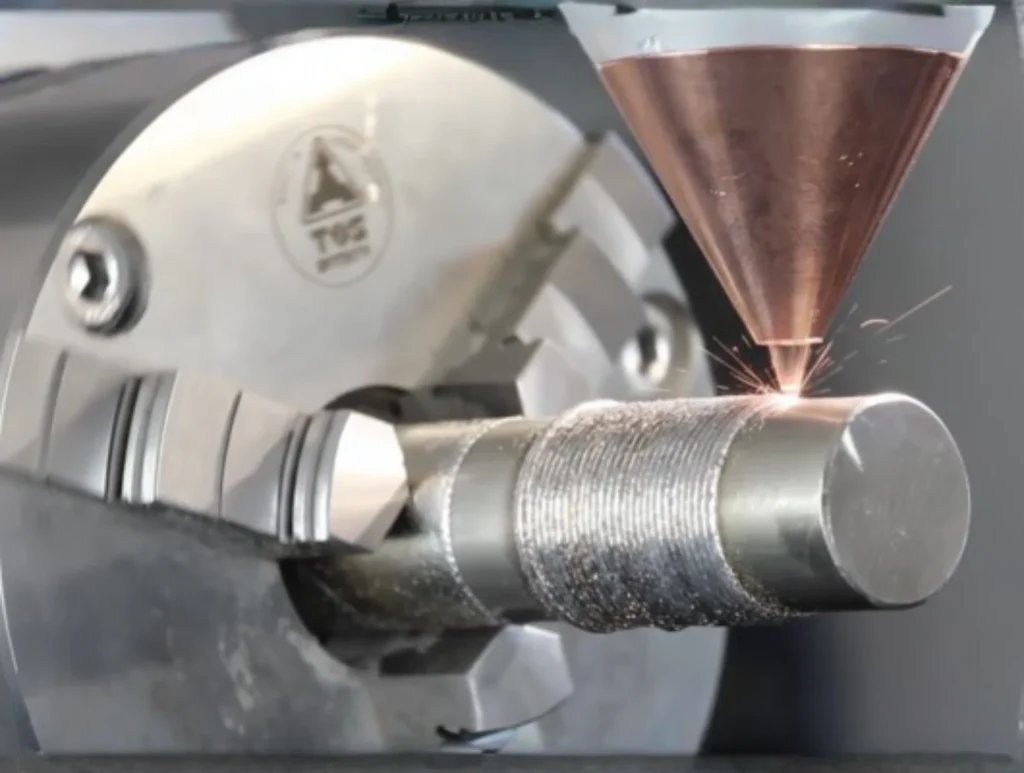

Laser Cladding and Repair

Application Demand

High-value aerospace components like turbine blades, compressor discs and structural parts

may need surface restoration or enhancement to improve wear, oxidation and corrosion

resistance. Conventional repairs often compromise on dimensional accuracy or material

properties.

What Laser Enables

Laser cladding enables localized material deposition with controlled dilution and minimal

HAZ. It restores surface geometry, enhances wear and corrosion resistance and extends

component life without affecting base material integrity.

Laser Ablation for Coating or Insulation Removal

Application Demand

Aerospace and defence components often require selective removal of coatings, oxides and

insulation layers prior to bonding, welding or assembly. Traditional mechanical or chemical

methods risk substrate damage or contamination.

What Laser Enables

Laser ablation provides precise, non-contact layer removal with micron-level control. It

preserves substrate integrity, ensures clean surfaces for subsequent processing and supports

high-throughput automated production.

Laser Cutting & Texturing of Advanced Composites

Application Demand

Aerospace structures increasingly use carbon fiber, thermoplastics and reinforced composites

for lightweighting. Cutting or texturing must maintain dimensional accuracy without fraying,

delamination or heat damage.

What Laser Enables

Laser cutting and texturing deliver clean edges and controlled surface features with minimal

thermal or mechanical impact. The process ensures dimensional precision, supports highstrength bonding, coating and painting, and is ideal for complex composite geometries.

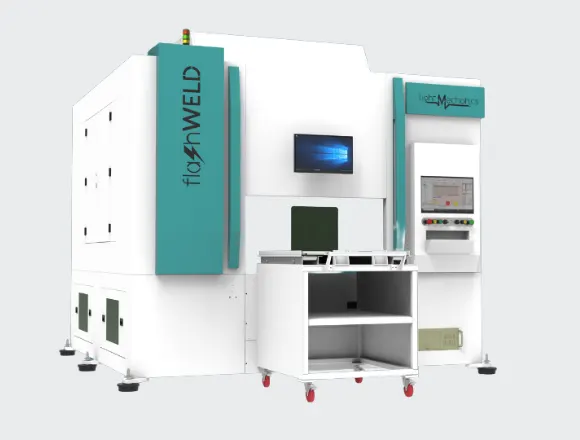

Why Choose Light Mechanics

Light Mechanics delivers application-driven laser solutions designed for the most demanding

aerospace and defence environments. Our systems combine high precision, automation

compatibility and scalability, enabling repeatable, zero-defect production at high volume

Laser Micro-Machining for Structural Components, Turbine Blades and Electronics.