Battery Laser Welding Machines for EV & Energy Storage

Light Mechanics offers advanced battery laser welding machines engineered for EV battery

manufacturing and energy storage systems (BESS). The FlashWeld portfolio supports

prismatic, cylindrical, blade, and sandwich busbar welding, delivering high weld integrity,

process stability, and scalable automation for mass production environments.

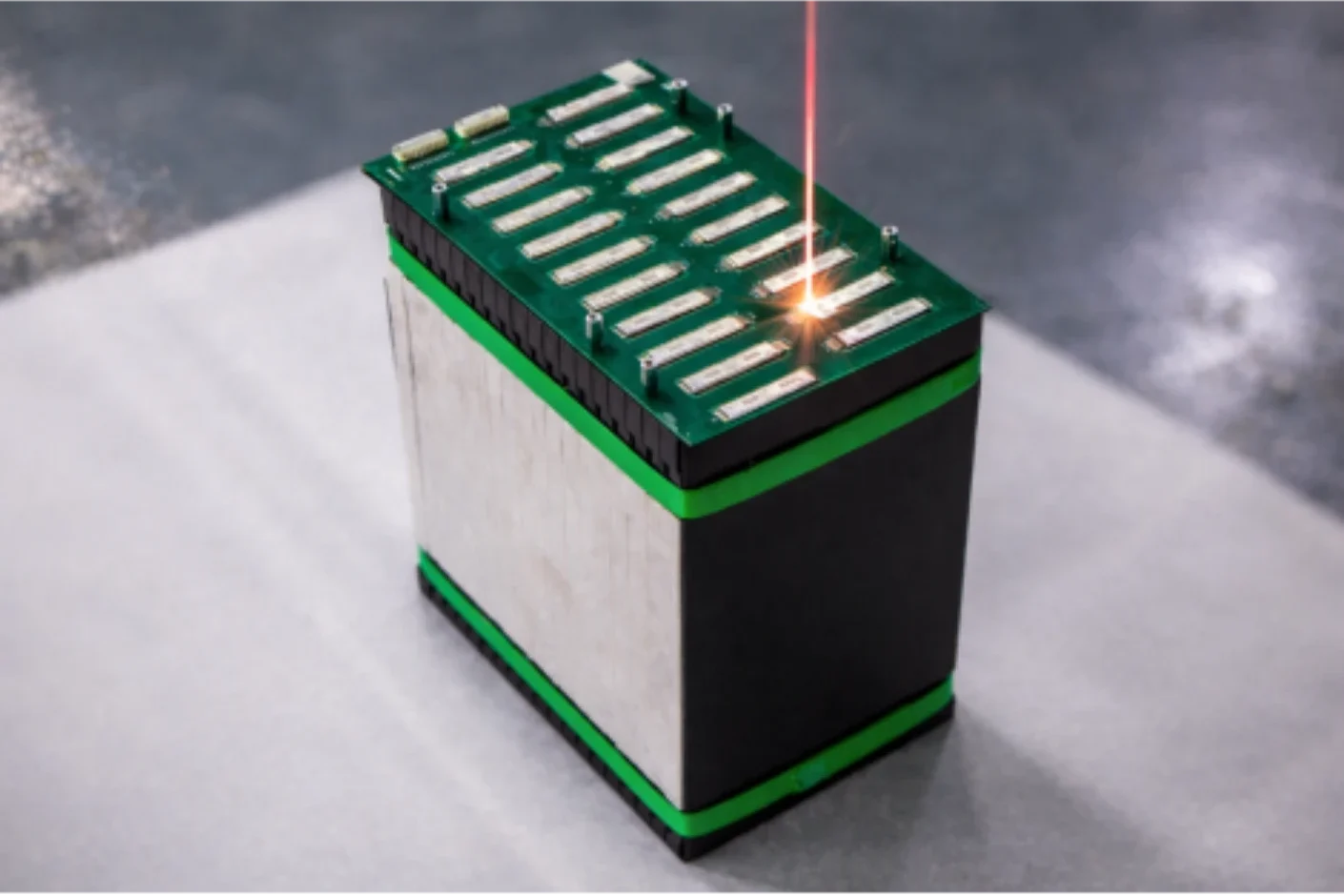

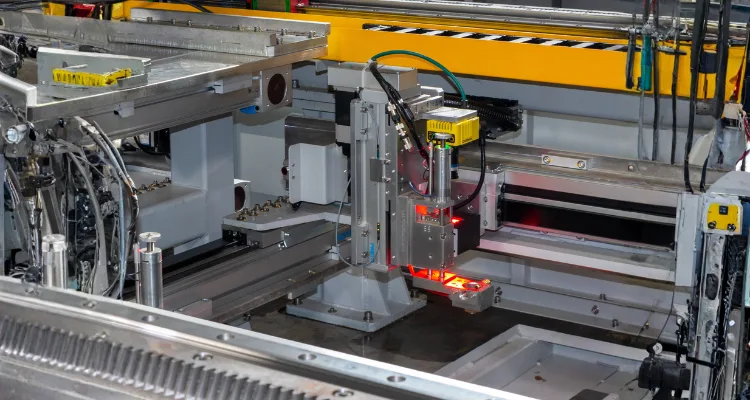

FlashWeld-CR

for Prismatic Battery Laser Welding

Specifically engineered for large-format prismatic battery cells including 100Ah, 200 Ah and

314 Ah used in EV and energy storage applications.

Key Capabilities

- Customized gantry dimensions based on battery module size

- Precision motion for cell-to-busbar and terminal welding

- Advanced vision systems for weld position correction

- Integrated press-and-weld systems to reduce air gaps

- In-built conveyor for automated line integration

- Upgradable with Inline Weld Monitoring System

- Integrated cooling, fume extraction and safety enclosures

The rigid gantry structure ensures precise and homogeneous welds with minimal thermal

distortion, critical for high-current battery applications.

Designed to maximize productivity using a dual pallet mechanism, enabling simultaneous

welding and loading/unloading. Integrated with XYZ Gantries or Robots for maximum

flexibility.

Key Capabilities

- Increased machine uptime

- Reduced cycle time

- Higher throughput for mass production

- Pneumatic Press-and-weld systems for air-gap reduction

- Gantry-based solutions for prismatic cells

- Vision-assisted weld position correction

- Robotic handling for prismatic and blade battery applications

- Upgradable with Inline Weld Monitoring System

- Integrated cooling, fume extraction and safety enclosures

Ideal for high-volume EV battery manufacturing, where throughput, consistency and

efficiency are critical.

FlashWeld-DP

Dual Pallet Prismatic Battery Laser Welding System

FlashWeld-R

Robotic Battery Laser Welding System

The FlashWeld-R is a robotic laser welding system engineered for heavy-weight prismatic

and blade battery packs used in EV and BESS applications. Integrated 6-axis industrial robots

provide maximum flexibility, precise seam access and consistent weld quality across large

and complex battery assemblies.

Key Capabilities

- High throughput for mass-production environments

- Integrated press-and-weld systems to minimize air gaps

- Vision-assisted weld position correction for improved accuracy

- Flexible, modular design enabling future automation upgrades

- Upgradable with Inline Weld Monitoring System

- Integrated cooling, fume extraction and safety enclosures

Ideal for large-dimension, heavy battery packs where manual loading and unloading are

impractical. The system meets critical requirements for precision, takt time and operational

efficiency in high-volume EV and energy storage battery manufacturing.

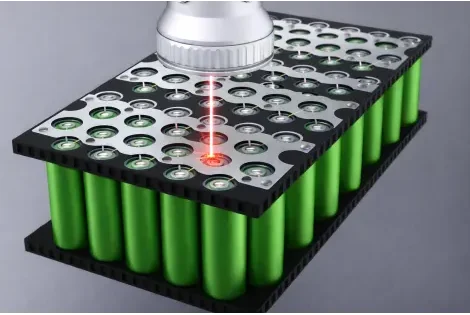

A flexible laser welding system with inbuilt flip mechanism for both cylindrical and

prismatic battery applications within a single platform.

Key Capabilities

- One machine supporting multiple battery formats

- Automated flip mechanism for top and bottom cylindrical battery pack welding

- Integrated conveyor system

- Vision-assisted weld position correction

- Press-and-weld mechanism for prismatic batteries

- Dedicated fixtures and jigs for cylindrical batteries

- Upgradable with Inline Weld Monitoring System

- Integrated cooling, fume extraction and safety enclosures

FlashWeld-CRF

Dual-Format Battery Welding System

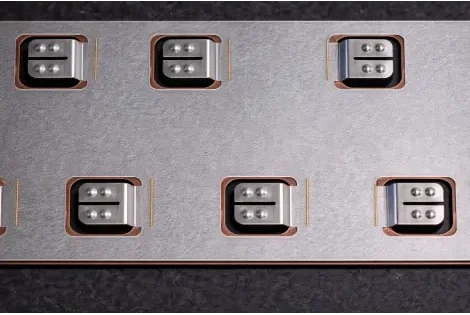

FlashWeld-RI

Sandwich Busbar Laser Welding Machine

A high-precision rotary indexer laser welding system designed for layered (sandwich)

busbars used in cylindrical EV battery applications. The system enables reliable welding of

dissimilar metal combinations such as Ni-Cu, Ni-Al, Clad-Cu, and Clad-Al with consistent

joint quality. This configuration allows welding to take place inside the machine while

operators simultaneously load and unload components outside, significantly improving

productivity and cycle time efficiency.

Key Capabilities

- High-precision laser welding for sandwich / layered busbars

- Non-contact welding with controlled heat input for minimal distortion

- Vision-assisted positioning

- Integrated cooling, fume extraction and safety enclosures

Ideal for Reliable joining of Ni–Cu, Ni–Al, Clad–Cu, Clad–Al, and other dissimilar metal

busbars, delivering high throughput, repeatable weld quality and scalable mass-production

capability.

Advanced Welding Intelligence & Process Control Features

Light Mechanics laser welding systems integrate advanced monitoring and control

technologies to ensure consistent weld integrity:

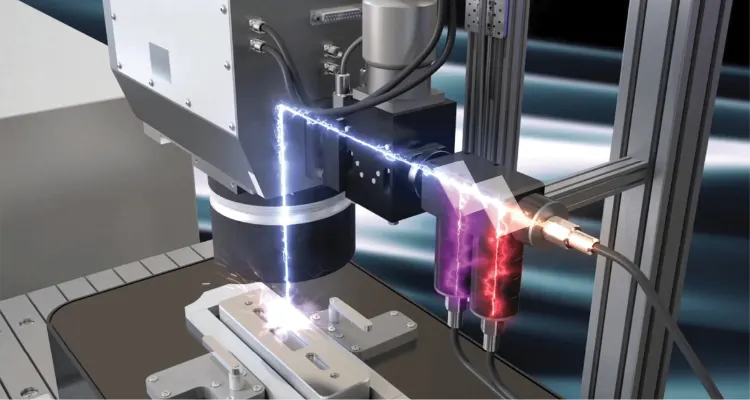

Inline Weld Monitoring

Continuously measures weld penetration depth, material height variation, energy input and transverse weld profiles, enabling real-time quality control, immediate defect detection and closed-loop process stability.

Height Validation System

The sensors detect height variations in cells and busbars and automatically adjust the Z-axis to maintain accurate laser focus, ensuring consistent weld penetration and uniform weld quality.

Vision System Integration

Integrated vision systems verify part presence, read barcodes for traceability and corrects XY positions within defined tolerances. This real-time adaptation improves repeatability, reduces scrap and enhances overall process reliability.

Industry 4.0 Integration

FlashWeld laser welding systems are designed for smart

manufacturing environments:

- PLC-based, recipe-driven welding programs

- MES integration for data logging and traceability

- Inline automation for reduced manual handling

- Fully customized layouts aligned with production workflow

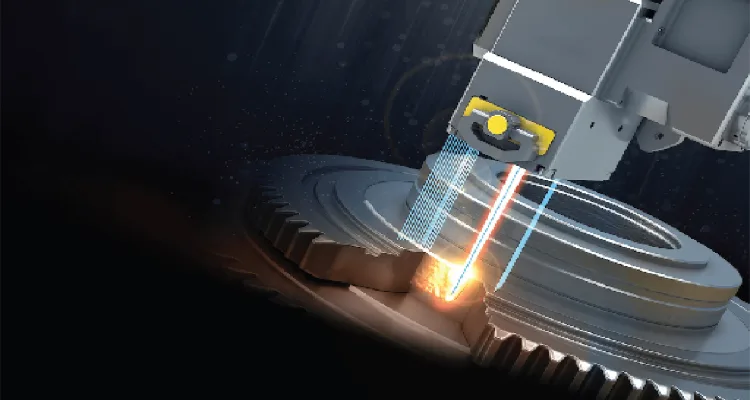

Laser Technologies Supported

FlashWeld laser welding systems support a wide range of industrial laser sources to match

application requirements:

- Continuous Wave (CW) lasers for deep penetration welding

- Pulsed and QCW lasers for controlled heat input and thin materials

- Single-mode and multi-mode lasers for precision, high power micro welding

- Dual beam lasers using core and ring technology for advanced, spatter-free and critical welding applications