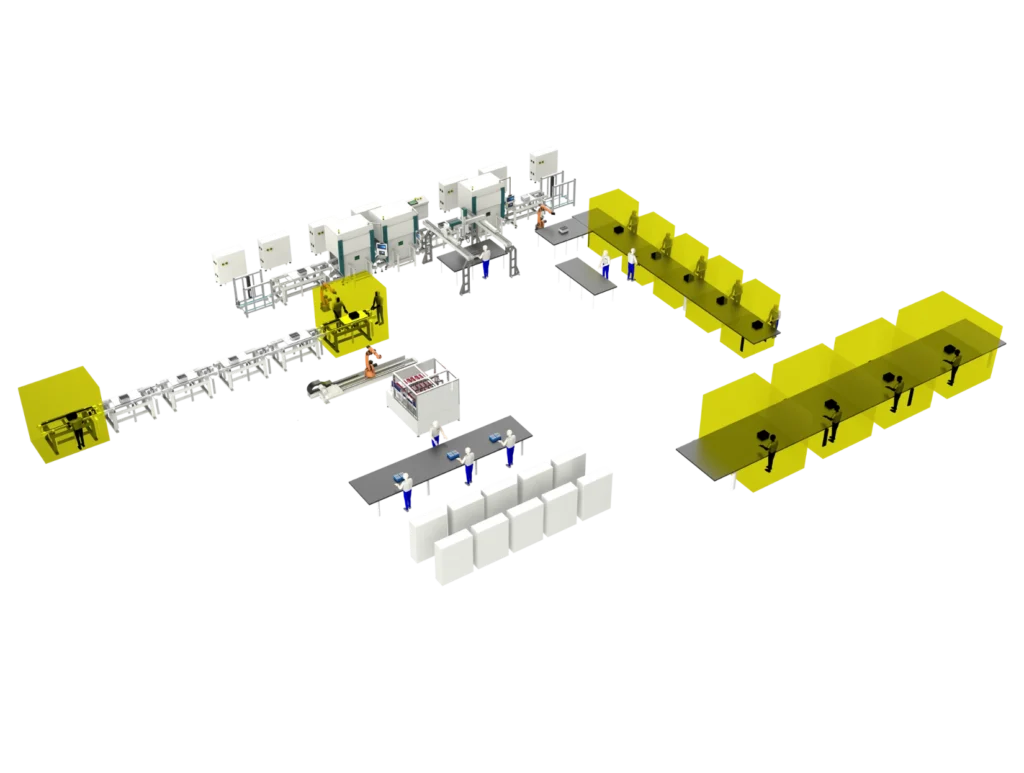

Prismatic Battery Assembly Line for EV & BESS Applications

As global demand for Electric Vehicles (EVs), solar inverters and Battery Energy Storage Systems (BESS) continues to accelerate, battery manufacturers are under increasing pressure to start battery assembly operations and scale production rapidly – without compromising quality, safety and cost efficiency.

Key Customer Challenges

- Starting battery pack assembly for the first time - From cell-to-module and module-to-pack, with flexibility and modularity for future upgrades

- Transitioning from pilot lines to full-scale manufacturing - With a reliable and experienced technology partner offering deep expertise in automation, scalable production systems and long-term post-warranty support, including spare parts and service availability.

- Ramping up battery production efficiently and cost-effectively - To meet fast-growing market demand

- Identifying and integrating the right testing processes - At each manufacturing stage to ensure safety, reliability and performance

At Light Mechanics, we work closely with automotive OEMs and battery manufacturers to address these challenges by delivering Semi-automated and fully automated prismatic battery assembly lines, integrated with reliable testing systems and designed for high throughput, precision and long-term scalability.

End-to-End Prismatic Battery Module & Pack Solutions

Our modular prismatic battery assembly solutions support a wide range of EV and BESS configurations, enabling manufacturers to scale production using repeatable, consistent and fully traceable automation.

From cell handling and sorting to laser welding, module formation, pack assembly and end-of-line (EOL) testing, every process step is engineered to ensure that only validated cells and modules move forward – protecting final pack integrity, safety and performance.

In addition, we partner with customers to train operators and maintenance teams, ensuring smooth production ramp-up, sustained uptime, and long-term operational confidence.

Battery Assembly Step-by-Step Process Flow

Cell CDC (Charge–Discharge Cycling)

- Identification of early-life defects and abnormal cell behaviour to prevent downstream failures

- Controlled charge and discharge cycling under defined current and voltage limits

- Measurement of cell capacity, efficiency and charge–discharge behaviour

- Monitoring of voltage response, temperature rise and current stability

Cell Sorting & Grading

- Open Circuit Voltage (OCV) testing to verify voltage consistency

- Internal Resistance (IR) measurement to assess electrical health

- Cell grading and electrical matching for uniform module performance

- Automatic discharge and removal of NG (non-conforming) cells to ensure safety and pack reliability

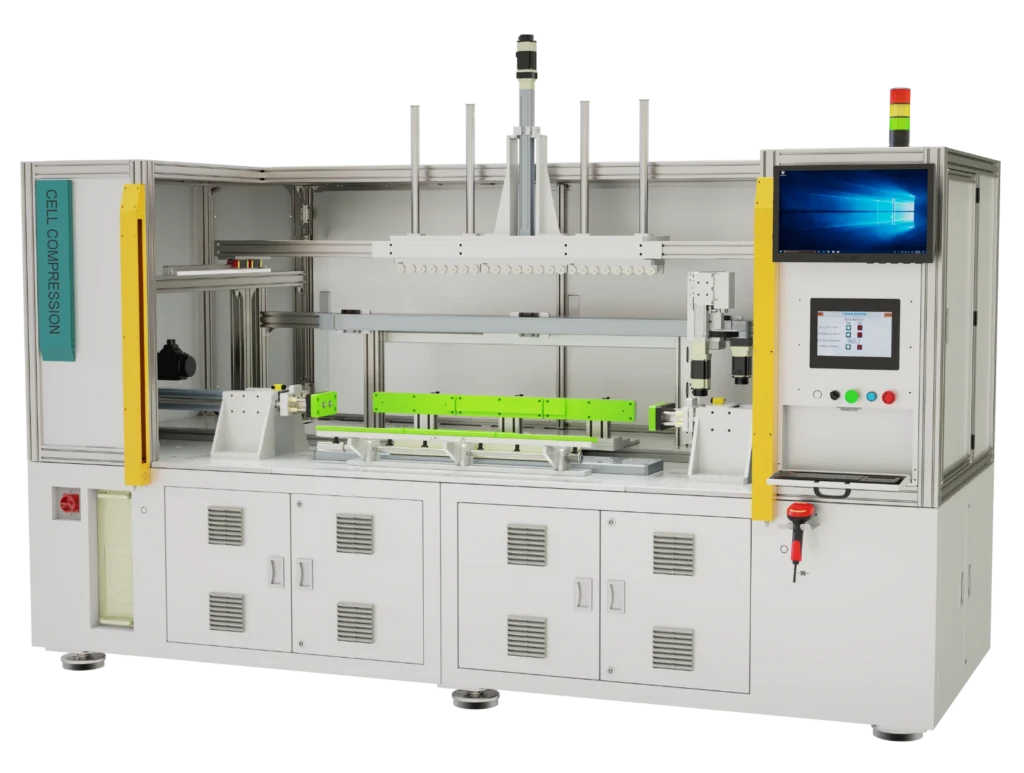

Module Stacking & Compression

- Manual or robotic stacking of sorted prismatic cells for accurate alignment and structural stability

- Application of adhesives and thermal insulation pads/interface materials

- Optional steel banding for enhanced mechanical integrity

- Vision inspection prior to compression to verify correct cell orientation and polarity, enabling early detection and correction of polarity mismatches

Polarity Detection & Laser Cleaning

- Vision systems verify correct cell orientation and define XY coordinates of terminals

- Laser cleaning removes oxides and surface contaminants from terminals and busbars for stable electrical connections

- Automatic NG (non-conforming) detection and rejection

Welding & Electrical Connections

- Manual or automated placement of busbars, FPCB and IBB on cell terminals

- Vision-guided weld alignment for accurate positioning and repeatable welds

- Precision laser welding of busbars for series and parallel connections

- Integrated press-and-weld mechanism to minimize air gaps and ensure joint quality

- Inline weld monitoring system for real-time quality assurance

Final Assembly & End-of-Line Testing

After module formation, battery packs undergo comprehensive final assembly and validation to ensure electrical integrity, safety, and functional performance.

- Module OCV / IR testing

- Placement of the battery pack bottom enclosure or cooling plate

- Cooling plate air leakage testing

- Box gluing and sealant application

- Installation and mechanical fastening of validated modules within the enclosure

- BMS installation and functional testing

- Wire harness installation and routing

- Top cover placement and sealing

- Pack-level air leakage testing

- Pack EOL / DCIR testing

- Pack charge–discharge testing

Automation, Traceability & Industry 4.0 Integration

At Light Mechanics, we understand that battery manufacturers require flexible automation architectures that can scale seamlessly as production volumes grow.

Automation Levels Supported

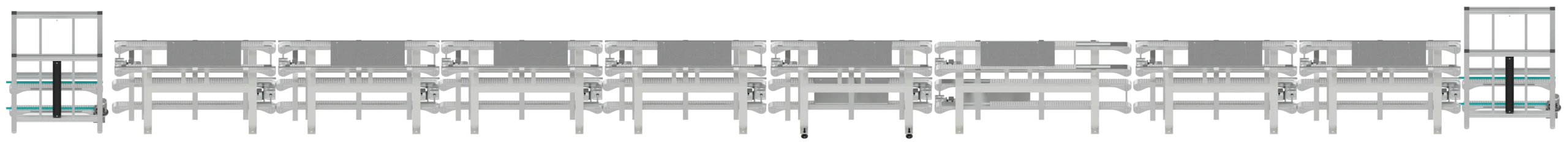

Semi-automated assembly lines for flexible, mid-volume production with operator-assisted stations

Fully automated inline assembly lines with robotic and gantry-based handling for high-throughput manufacturing

Industry 4.0 Capabilities

- Complete cell-to-module-to-pack traceability

- Real-time process and test data collection for quality and performance monitoring

- Seamless MES and factory system integration

- OEE monitoring and advanced quality analytics to optimize productivity and reduce defects

Backed by in-house engineering, system integration, commissioning and long-term support, our solutions enable manufacturers to build safer, more reliable and future-ready battery systems.

Cell & Battery Testing Machines – A One-Stop Solution

Light Mechanics provides cell and battery testing machines as a complete one-stop solution for EV and BESS manufacturers. As the authorized distributor of Neware and Repower battery testing systems, we deliver globally proven technologies supported by local engineering and service expertise.

From cell-level charge–discharge cycling to module and pack EOL testing, our solutions provide reliable performance, accurate data, and long-term service support – enabling manufacturers to build safe, high-quality and compliant EV and BESS battery systems with confidence.

Reach out to us if you are looking to design, automate, and scale your prismatic battery assembly line.