Laser Applications in Automotive & Powertrains Manufacturing

The automotive industry is undergoing a fundamental transformation driven by

electrification, lightweighting, stricter efficiency standards and increasing production

automation. From internal combustion engines (ICE) to hybrid and electric powertrains,

manufacturers must adopt manufacturing processes that deliver precision, consistency,

scalability and full process reliability.

Laser-based manufacturing has become a core production technology across automotive

body, powertrain, electric vehicle (EV) and battery manufacturing. Its ability to deliver

controlled energy, non-contact processing and digital repeatability makes it uniquely suited

for modern automotive environments where quality, throughput and traceability are critical.

Light Mechanics supports these requirements with application-driven laser solutions designed

to perform reliably in demanding, high-volume automotive production.

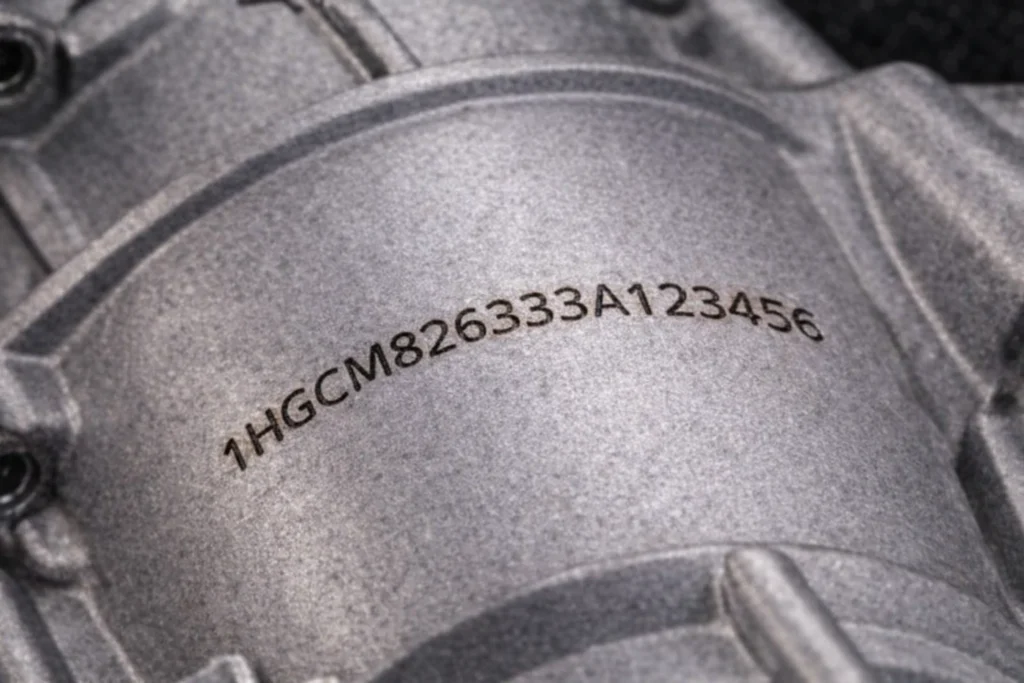

Automotive Traceability & Identification

(VIN & Part Identification)

Application Demand

Automotive manufacturing requires permanent, reliable traceability to meet regulatory

compliance, quality control, recalls and anti-counterfeiting needs. Markings must remain

legible through coating, heat, abrasion and the full service life of the vehicle. All critical

components including – seat rails, gears, bearings, motor housing, inverter case, transmission

case, engine blocks, rear view mirrors, tyres, wipers etc require mandatory laser marking for

traceability.

What Laser Enables

Laser marking creates permanent, high-contrast identification directly on the material without

consumables or contact. It enables fast, inline marking of VINs and part codes, ensuring end-to-end traceability from production to field use.

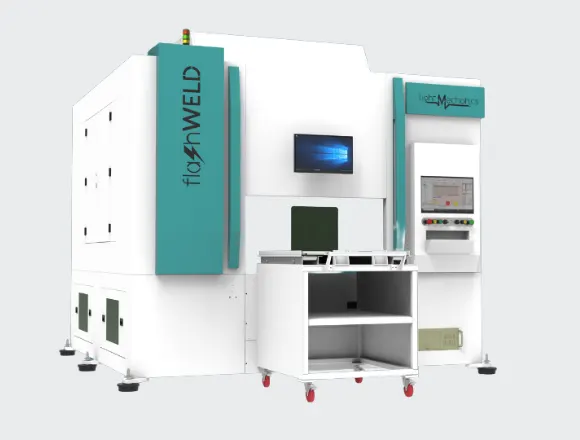

FlashWeld-CR for Prismatic Battery Laser Welding

Application Demand

Automotive manufacturing requires permanent, reliable traceability to meet regulatory

compliance, quality control, recalls and anti-counterfeiting needs. Markings must remain

legible through coating, heat, abrasion and the full service life of the vehicle. All critical

components including – seat rails, gears, bearings, motor housing, inverter case, transmission

case, engine blocks, rear view mirrors, tyres, wipers etc require mandatory laser marking for

traceability.

What Laser Enables

Laser marking creates permanent, high-contrast identification directly on the material without

consumables or contact. It enables fast, inline marking of VINs and part codes, ensuring endto-end traceability from production to field use.

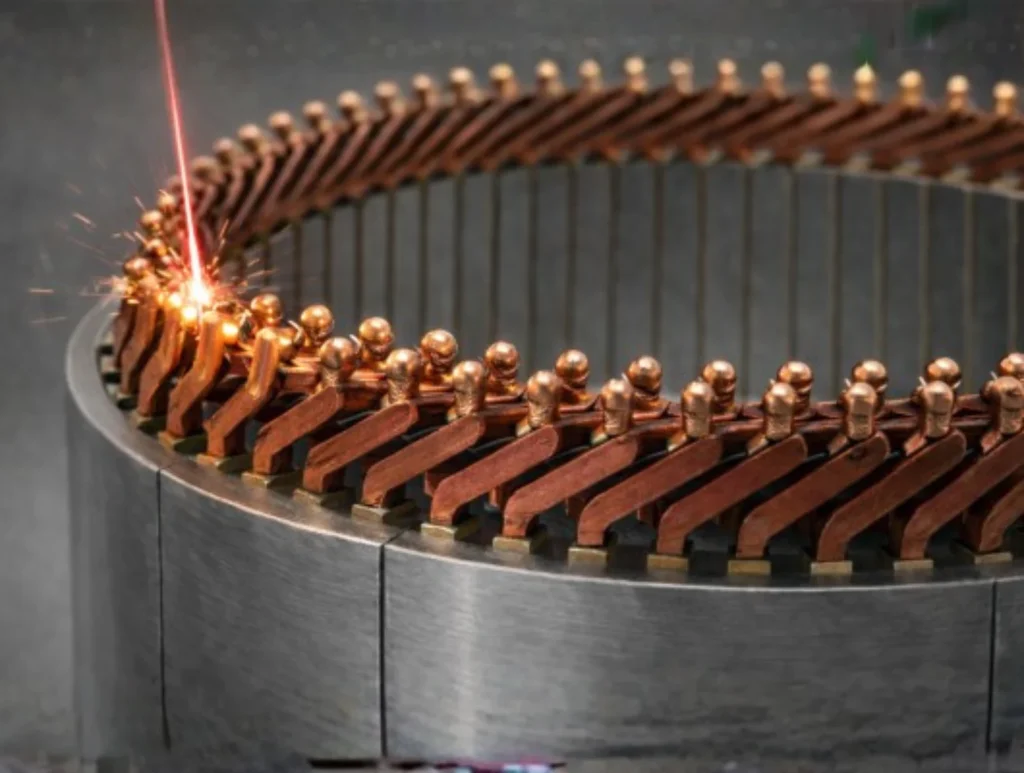

Copper Hairpin Welding for EV & Hybrid Motors

Application Demand

Electric motor performance depends directly on the quality of copper hairpin joints. These

welds must deliver low electrical resistance, high mechanical strength and long-term thermal

stability and minimizing defects.

What Laser Enables

Laser welding provides precise, localized energy delivery that makes it possible to join

copper reliably despite its high reflectivity and thermal conductivity. The process enables

deep, consistent penetration with minimal spatter, supporting high-speed stator production

and repeatable electrical performance in EV and hybrid motors. The insulation coatings are

laser cleaned before welding.

Fuel Tank Laser Welding

Application Demand

Automotive fuel tanks require continuous, pore-free and leak-proof welds that maintain

integrity under vibration and pressure fluctuations. Any distortion or

inconsistency can result in emissions failures and safety risks. The welded structure must also

withstand harsh operating environments, sustained vibration and external mechanical impacts

throughout the vehicle’s service life.

What Laser Enables

Laser welding allows fuel tank halves to be precisely cut, accurately aligned with proper

fixturing and butt welded with controlled heat input. The process produces uniform, hermetic

seams with minimal distortion, ensuring structural integrity and consistent quality at high

production volumes, making it ideal for automotive fuel tank manufacturing.

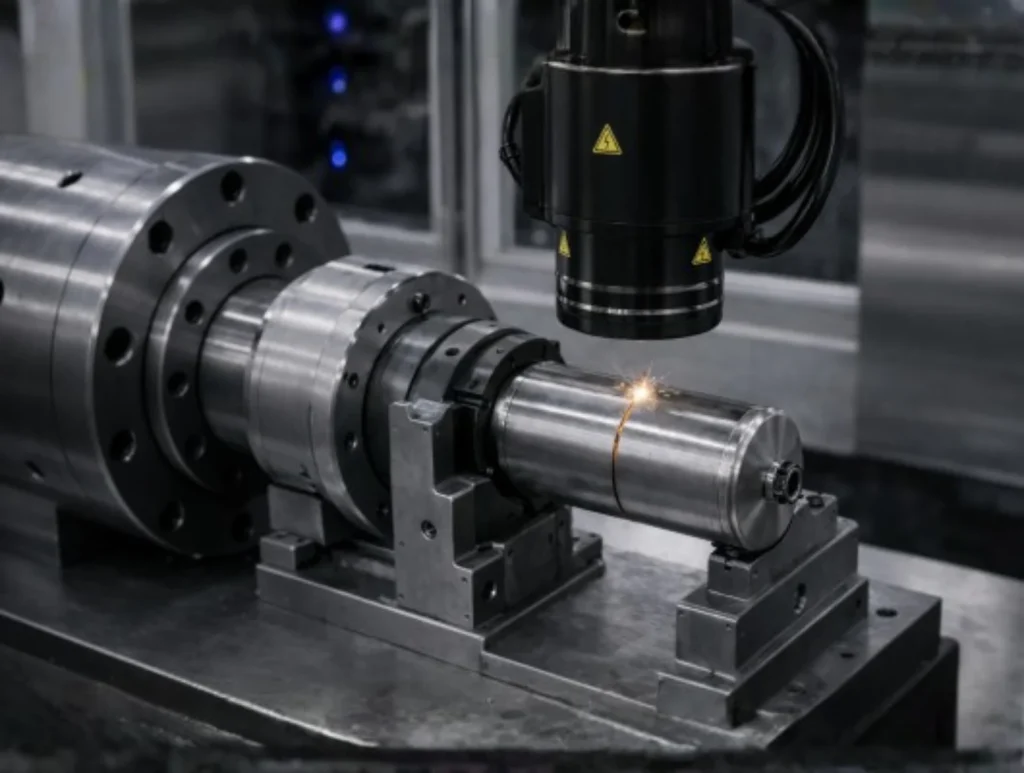

Gear Welding

Application Demand

Gear assemblies require precise joining with minimal distortion to preserve tooth geometry

and ensure quiet, efficient operation. Weld consistency is critical for fatigue strength, tight

tolerances and long-term durability, with a strong emphasis on achieving deep penetration

without thermal distortion.

What Laser Enables

Laser welding delivers deep, consistent penetration with highly localized heat input,

minimizing deformation and preserving gear accuracy. The process produces strong,

repeatable joints without filler material or post-processing, ensuring reliable performance

under cyclic loads.

Body-in-White (BIW) Laser Welding

Application Demand

Body structures must combine lightweight design, structural strength, and dimensional

accuracy to meet crash safety and efficiency targets. High production rates and repeatability

are essential in body shops.

What Laser Enables

Laser welding supports high-speed joining of structural and tailored blank components,

enabling thinner materials and optimized joint designs. The result is lighter vehicle bodies,

consistent weld quality and reduced cycle times.

Airbag Inflator Laser Welding

Application Demand

Airbag inflators are safety-critical components that require absolute sealing reliability. Welds

must maintain structural integrity under pressure and vibration, with minimal distortion, to

ensure the airbag deploys correctly in an emergency. Any weld inconsistency can

compromise safety performance.

What Laser Enables

Laser welding produces deep, high-strength and precise joints with minimal heat-affected

zones and deformation. The process is non-contact, filler-free and pollution-free, delivering

consistent, hermetic seals that meet the stringent reliability and safety requirements of

automotive airbag systems.

Rotor–Stator Welding for Electric Motors

Application Demand

Rotor and stator assemblies are critical to electric motor efficiency, torque output and

durability. Manufacturing requires precise joining of stacked laminations and conductive

components while maintaining electrical insulation, magnetic performance and structural

integrity. Any distortion or inconsistency can impact motor balance, noise, efficiency and

high-speed operation.

What Laser Enables

Laser welding offers high precision, fast processing speeds and distortion-free joints with

minimal heat-affected zones, producing strong, reliable welds in thin laminations. This is

critical for reducing eddy current losses, preserving lamination alignment and insulation

integrity and ensuring rotor stability at high RPMs.

Tyre Inner-Liner Cleaning

Application Demand

Precisely remove release agents, oils and contaminants from a tyre’s interior surface to

prepare it for bonding with sealants or foam without damaging the rubber.

What Laser Enables

Laser cleaning delivers consistent, high-speed and automated tyre cleaning with minimal

heat-affected zone (HAZ) and no burning. The process improves adhesion for self-sealing

and silent tyres while reducing waste and environmental impact compared to traditional

mechanical or chemical methods.

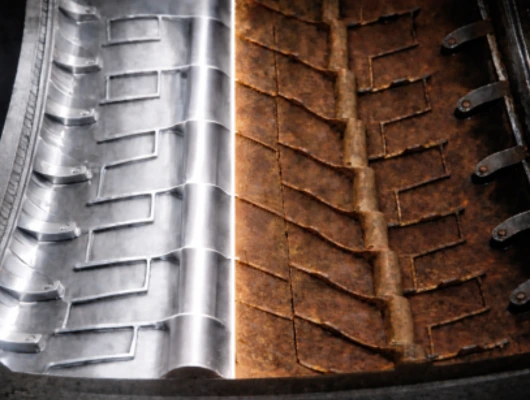

Tyre Mold Cleaning

Application Demand

Tyre molds are critical for surface finish quality, bonding consistency, dimensional accuracy

and mold longevity. Residue buildup from rubber compounds and release agents can cause

defects and increased scrap rates, while chemical and abrasive cleaning methods risk damaging

sensitive mold surfaces.

What Laser Enables

Laser cleaning removes rubber residues and contaminants without physical contact,

preserving mold geometry and surface texture. The process eliminates the use of chemicals

and abrasives, enabling repeatable cleaning, improved product quality and extended mold

service life.

Why Choose Light Mechanics

Light Mechanics delivers application-driven laser solutions designed to meet the most

demanding requirements of modern automotive manufacturing. Our systems combine high

precision, automation compatibility and scalability, enabling repeatable, zero-defect

production at high volumes. With deep expertise across automotive and powertrain industry,

Light Mechanics empowers manufacturers to achieve superior quality, consistent traceability

and long-term reliability. Our laser systems support faster cycle times, minimal material

distortion and environmentally friendly processes, helping automotive manufacturers meet

regulatory standards and exceed industry performance expectations.