Precision in Motion: The Power of Laser Cross Welding

Overcoming the Challenges of Continuous Coil Joining with Precision Laser welding Technologies

Introduction

Why Laser Cross Welding Matters

In continuous metal strip processing lines such as electrical steel manufacturing, annealing

lines, slitting lines, and lamination production coil end joining is a critical operation. Any

interruption, weak joint, or dimensional inconsistency directly impacts productivity,

downstream machine stability, and final product quality.

Joining ultra-thin metallic strips (30 µm to 500 µm) is especially challenging. Conventional

joining methods such as mechanical shearing followed by resistance or arc welding struggle

with:

- Edge deformation and burr formation

- Excessive heat input

- Poor joint alignment

- Large heat-affected zones (HAZ)

- Reduced magnetic or mechanical properties

Laser Cross Welding addresses these challenges by enabling precise, low-heat, high-speed

butt welding, specifically engineered for thin and sensitive materials.

The Fundamental Challenge: Welding Ultra-Thin Strips

1. Thickness Sensitivity

Ultra-thin strips (as low as 30–50 microns) are extremely sensitive to:

- Heat input fluctuations

- Beam misalignment

- Clamping inaccuracies

Even minor instability can cause:

- Burn-through

- Excessive bead height

- Distortion or tearing

2. Edge Preparation and Alignment

Traditional coil joining systems rely on:

- Mechanical punching or shearing

- Separate cutting and welding stations

This introduces:

- Burrs on cut edges

- Inconsistent joint gaps

- Misalignment during transfer

For thin materials, even a 20–30 µm gap can cause incomplete fusion or weak joints.

3. Heat-Affected Zone (HAZ) Control

In applications like GOES / NGO electrical steel, excessive HAZ can:

- Degrade magnetic properties

- Increase core losses

- Reduce transformer efficiency

Conventional welding processes struggle to limit HAZ when joining long strip widths at

speed.

4. Continuous Production Constraints

In annealing or slitting lines:

- Coil changeover time must be minimal

- Floor space is limited

- Process repeatability is critical

Multiple stations and manual intervention increase downtime and variability.

Light Mechanics Laser Cross Welding Solution

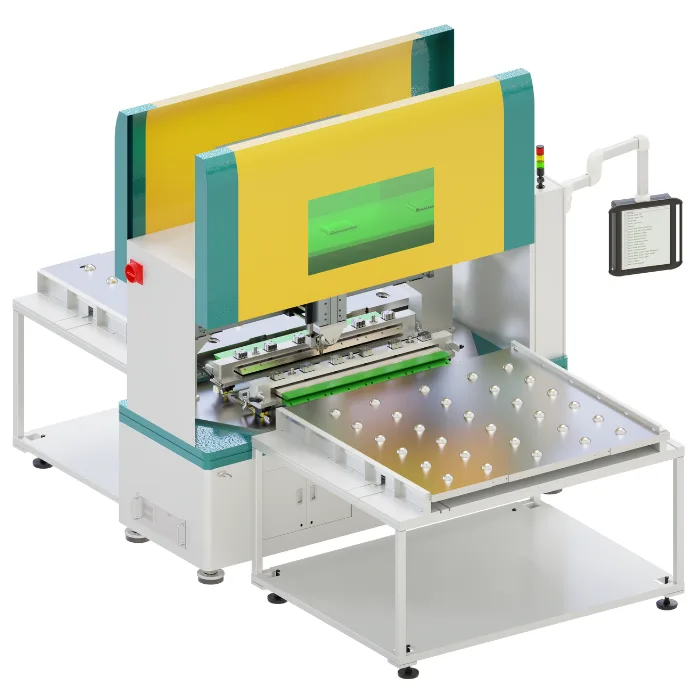

Light Mechanics has engineered a purpose-built Laser Cross Welding Machine designed

specifically to handle:

- Ultra-thin metallic strips

- High-speed coil joining

- Inline or batch operation

Key Design Philosophy

Minimize handling, minimize heat input, and maximize repeatability

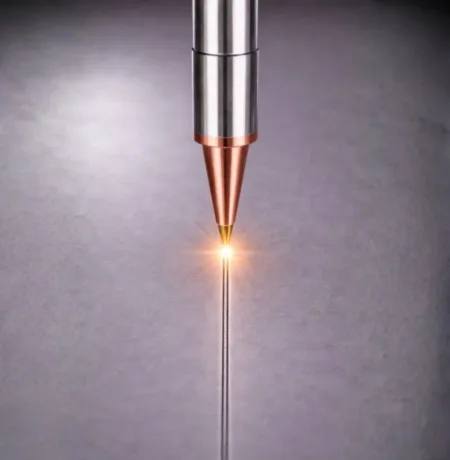

Single Laser Head – Multiple Functions

One of the core strengths of the system is the use of a single fibre laser head that performs:

- 1. Precision cutting of strip ends

- 2. Butt welding at controlled energy density

- 3. Localized pre-heating for post-processing

- 4. Laser notching for weld identification

All operations are software-controlled no mechanical repositioning required.

Precision Fixturing for Thin Materials

Inclined Fixture Concept

Instead of cutting the strip edges at an angle, the fixture itself is oriented at ±15°, while the

strips remain straight.

This provides:

- Higher dimensional accuracy

- Better repeatability

- Simplified alignment

Clamping & Alignment

- Pneumatically actuated clamps

- Spring-loaded anodized base for thermal stability

- Proximity sensors to confirm true butt contact

This ensures zero overlap and zero gap before welding.

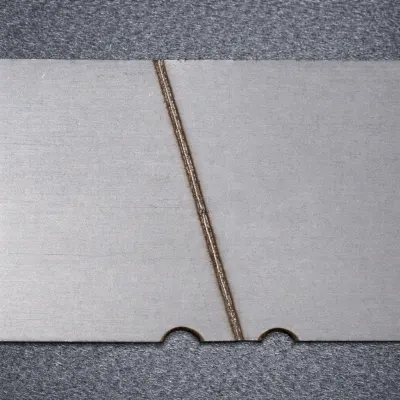

Post-Weld Conditioning: A Critical Advantage

Pre-Heating

Immediately after welding, the joint is locally pre-heated using the same laser head.

This softens the weld region and prepares it for flattening.

Pneumatic Hammering

- Low-force hammering (4–5 strokes)

- Hardened embossed support surface

- Final bead height ≤ 50% of base material thickness

This ensures:

- Smooth strip passage through rollers

- No interference in downstream processes

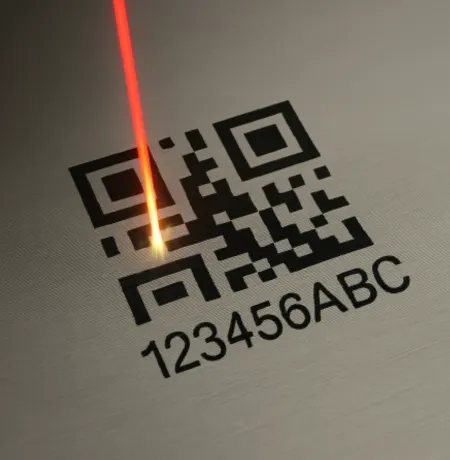

Laser Notching for Smart Identification

A unique feature of the system is laser-based notching at the strip edge:

- Semi-circular notch

- Marks the welded joint location

- Enables easy exclusion during final product cutting

This is particularly useful in transformer core manufacturing.

Performance Benefits

Operational

- Coil joining time < 30 seconds

- Reduced downtime

- Compact footprint

Quality

- Burr-free edges

- Minimal HAZ

- High mechanical integrity

- No degradation of magnetic properties

Flexibility

- Widths: 5 mm to 1045 mm

- Thickness: 30 µm to 3000 µm

- Coated & uncoated materials

Conclusion: Engineering Beyond Welding

Laser Cross Welding is not just a joining process it is a system-level engineering solution.

By integrating:

- Precision laser processing

- Intelligent fixturing

- Inline post-weld conditioning

Light Mechanics delivers a solution that solves real industrial challenges, especially in ultrathin material processing, where conventional technologies fail.

Article By: