Femtosecond Laser Technology: Redefining Ultra-Precision Manufacturing

As industries move toward miniaturization, manufacturing at the micro and nano scale

demands a level of precision that conventional machining and even standard laser processes

struggle to achieve. Heat input, material distortion, burr formation and tool wear often limit

accuracy and repeatability. Femtosecond laser technology addresses these challenges by

enabling true cold processing – making it a true game changing laser technology for nextgeneration manufacturing.

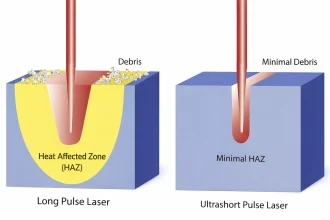

What Is Femtosecond Laser Technology?

Femtosecond (fs) lasers operate with pulse durations as short as 10⁻¹⁵ seconds, enabling

material removal to occur before heat can diffuse into the surrounding area. This phenomenon, known as cold ablation, eliminates thermal damage entirely.

- No melting

- No burrs

- No heat-affected zone (HAZ)

- No material distortion

- No burning

This makes femtosecond lasers ideal for high-value, heat-sensitive, and micro-scale applications where traditional processes fail.

Manufacturing Advantages of Femtosecond Laser Processing

Unlike thermal or mechanical methods, femtosecond laser processing delivers consistent

quality without compromising material integrity.

Key advantages include:

- Sub-micron machining accuracy

- Zero or near-zero heat-affected zone

- Burr-free edges and sharp feature definition

- Minimal taper and high vertical sidewalls

- No tool wear or mechanical stress

- Stable performance in high-density production environments

These advantages directly translate into higher component reliability and reduced

downstream processing.

Materials Enabled by Femtosecond Lasers

Femtosecond lasers offer material independence, making them suitable for applications

previously considered difficult or impossible to machine:

- Metals and metal alloys

- Glass and transparent substrates

- Technical ceramics

- Polymers and flexible films

- Composite materials

- Diamond and super-hard materials

This versatility enables a single platform to support diverse industries and product lines.

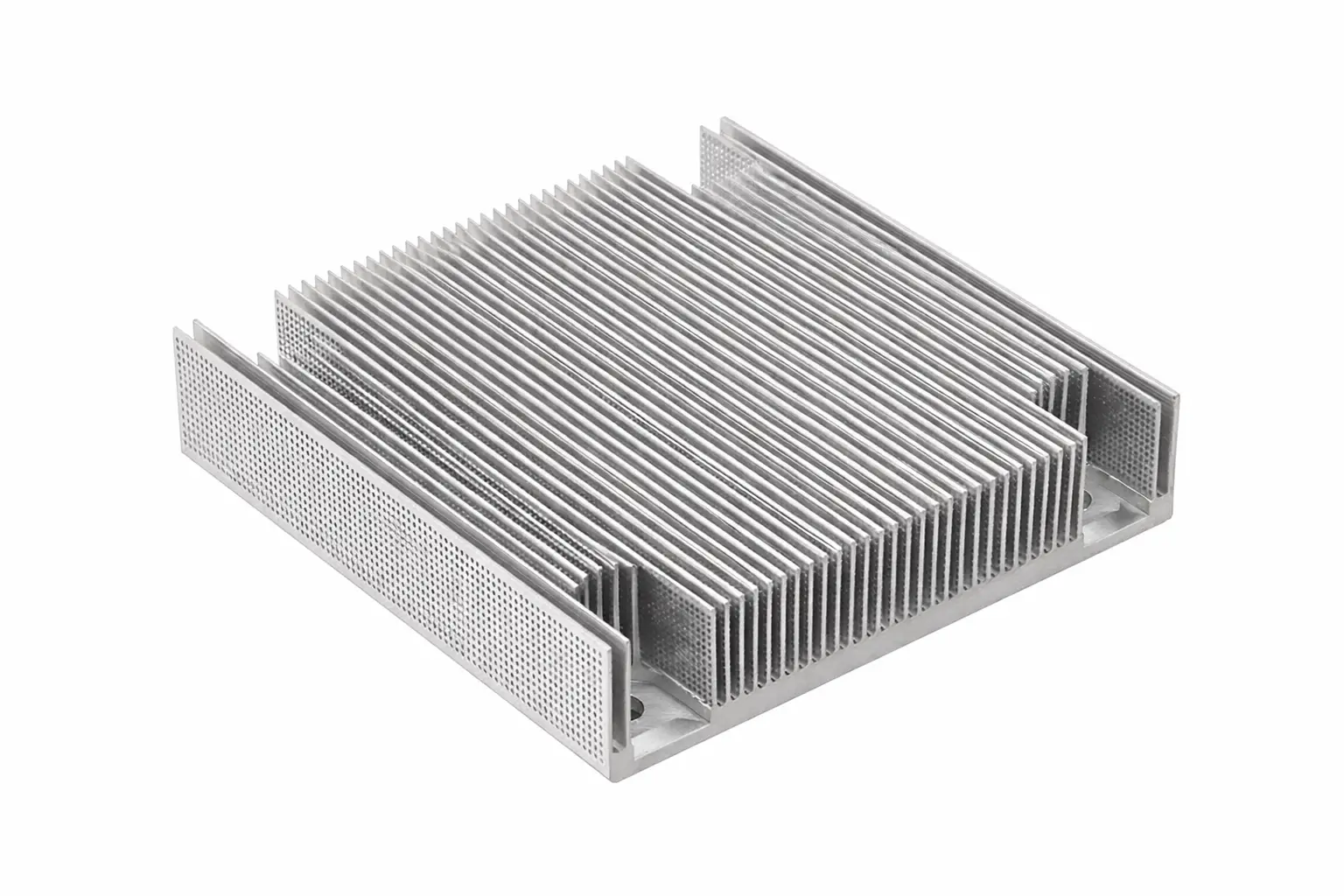

Technical Focus: Blind Hole Machining

Blind holes – features with controlled depth that do not fully penetrate a material – are

common in electronics, sensors and microfluidic systems. Achieving consistent depth, flat

bottoms, and vertical sidewalls is challenging with conventional methods.

Femtosecond laser machining enables:

- Micron-level depth control

- Near-zero sidewall taper

- Smooth, flat hole bottoms

- High repeatability in dense hole arrays

These capabilities are essential for high-performance micro-devices where geometry directly

impacts functionality.

Femtosecond Laser Applications

Electronics & Semiconductors

- Micromachining silicon carbide, creating micro-holes in chips.

- Manufacturing microfluidic devices and tiny electronic components.

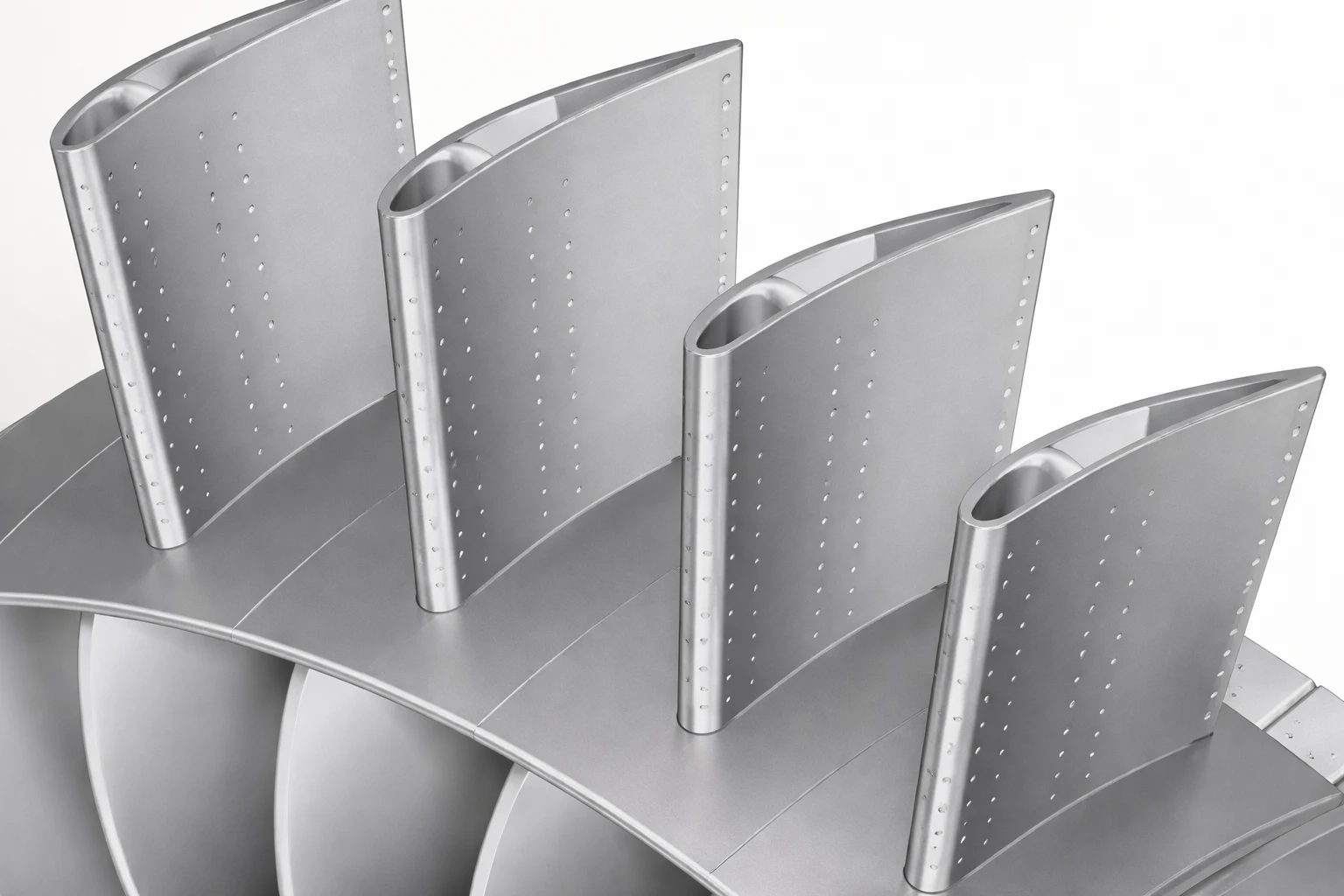

Automotive

- Precision drilling in turbine blades (cooling holes).

- Processing advanced ceramics, composites and high-temperature alloys.

Luxury Goods

- Creating intricate surface textures and patterns on metals replacing chemical etching.

Aerospace

- Micro-drilling and machining components for complex geometries.

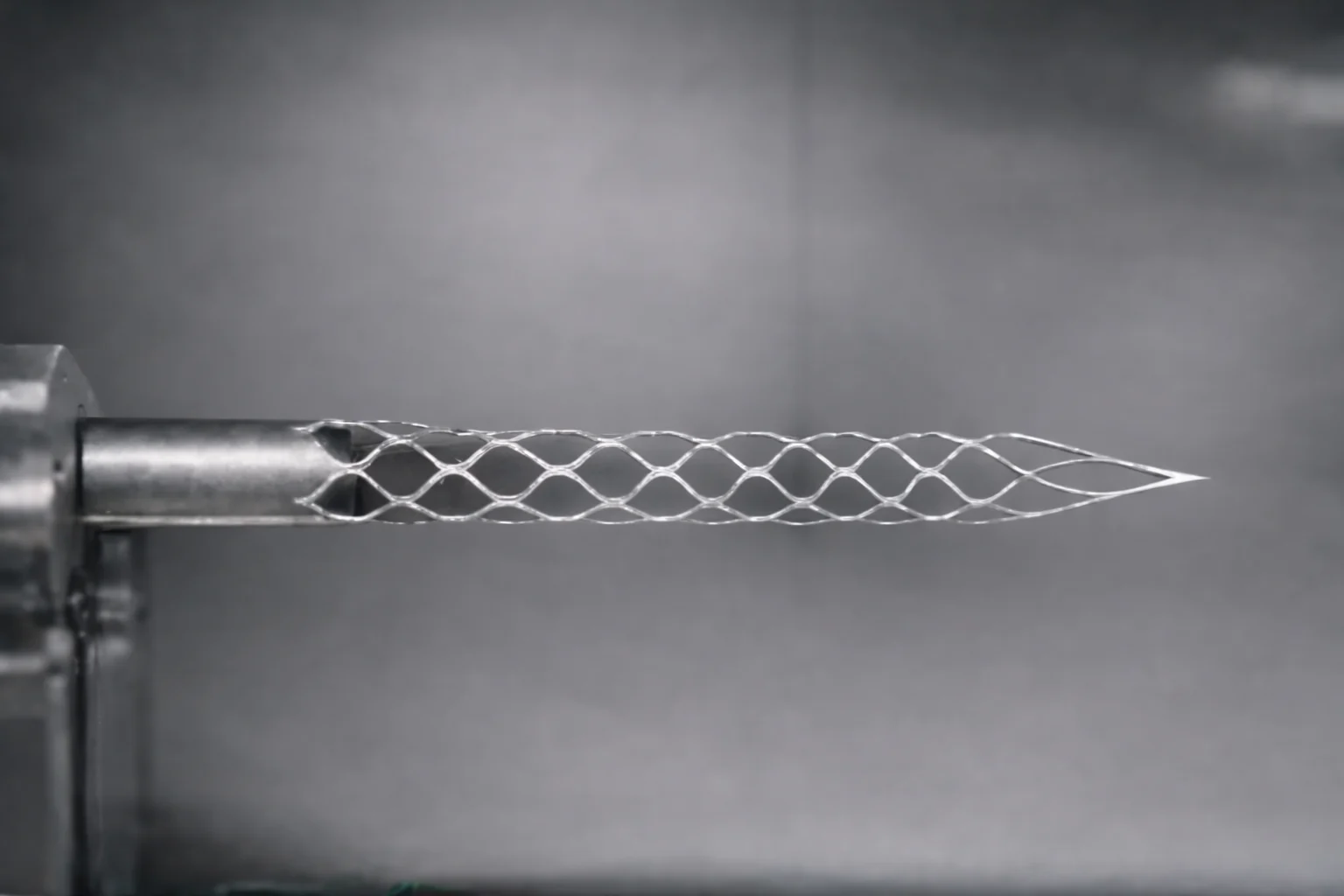

Medical Devices and Healthcare

- Distortion-free machining of micro-filters, neural electrodes, stents, implants and surgical tools

Research & Development

- Fundamental studies in physics, chemistry and material science.

Technical Focus: Blind Hole Machining

Femtosecond laser technology is not just an incremental improvement – it represents a

fundamental shift in how materials are processed at the micro scale. By removing thermal

limitations and enabling distortion-free machining, it opens new possibilities in product

design, material selection and performance.

With the introduction of femtosecond laser solutions, Light Mechanics is preparing to support advanced manufacturing needs across electronics, semiconductors, medical devices, automotive, aerospace, defence and microfluidics – delivering precision where it matters most.

With the introduction of femtosecond laser solutions, Light Mechanics is preparing to support advanced manufacturing needs across electronics, semiconductors, medical devices, automotive, aerospace, defence and microfluidics – delivering precision where it matters most.